A method for producing low-silicon flux pellets with a large-scale belt roaster

A belt-type roaster and flux-based technology, which is applied in the fields of iron and steel smelting and pellet production, to achieve the effects of reducing slag ratio, improving furnace grade, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

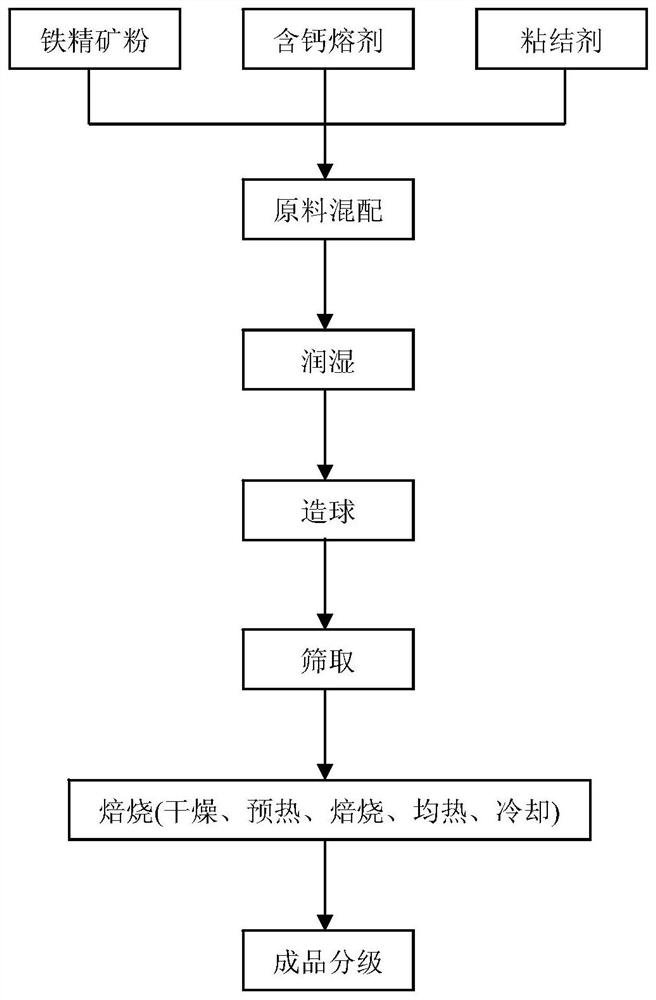

[0024] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0025] The prepared raw materials (including iron concentrate powder, calcium-containing flux, and binder) are compounded, wetted, pelletized, roasted, and classified to obtain finished low-silicon flux pellets. Specific steps are as follows:

[0026] a. Raw material preparation: iron concentrate powder (TFe 69.65%, SiO 2 1.76%, particle size-200 mesh 83.30%), slaked lime powder (CaO 64.73%, particle size-200 mesh 91.26%), bentonite (SO 2 51.23%, blue absorption 31.27%, expansion multiple 19.61, water absorption 467.85);

[0027] b. Compounding: Mix 96.4% of iron concentrate powder, 3.5% of slaked lime powder, and 0.4% of bentonite in proportion, and mix them evenly in a powerful mixer with a mixing efficiency >98%;

[0028] c. Wetting: add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com