Method for synthesizing nitrile from aldoxime

An aldoxime and compound technology, applied in the field of synthesizing nitrile, can solve the problems of large amount, unsuitable for mass production, expensive palladium catalyst and the like, and achieves the effects of high yield, easy availability of raw materials and strong atom economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

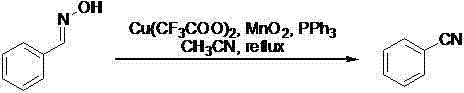

[0016] 1. Reaction formula:

[0017]

[0018] 2. Raw materials and properties of each raw material:

[0019] substance molecular weight millimoles Mass / g Volume / mL Benzaldehyde oxime 121 200 24.2 copper trifluoroacetate 289.6 2 0.58 manganese dioxide 87 6 0.52 Triphenylphosphine 262 8 2.10 Acetonitrile 400

[0020] 3. Operation process:

[0021] Add benzaldoxime, copper trifluoroacetate, manganese dioxide, triphenylphosphine, and acetonitrile in sequence in a 1 L round bottom flask, connect the reflux condenser, and stir under reflux (81°C) (the amount of feed is shown in the table above ). The reaction solution gradually turned yellow. The reaction was monitored by thin-layer chromatography (developing solvent: petroleum ether / ethyl acetate 6:1). The reaction was completed after 12 h, and the distillation device was connected for distillation, and the solvent acetonitrile (79-81 ℃...

Embodiment 2

[0023] 1. Reaction formula:

[0024]

[0025] Other aldoximes are used to replace benzyl aldoxime, and other conditions are the same as in Example 1, and the experimental results are shown in the following table.

[0026]

[0027] Numbering R Yield(%) 1 p -MeC 6 h 4 95 2 p -MeOC 6 h 4 91 3 p-HOC 6 h 4 88 4 p -Bu t C 6 h 4 71 5 4-Me 2 NC 6 h 4 74 6 p -ClC 6 h 4 72 7 p -BrC 6 h 4 84 8 m-BrC 6 h 4 61 9 m-NO 2 C 6 h 4 70 10 E -C 6 h 5 CH=CH 70 11 C 7 h 15 96

[0028] It can be seen from the above table that this reaction has a wide range of applications, and no matter aromatic aldoxime, alkyl aldoxime or cinnamyl aldoxime can be easily converted into nitriles.

Embodiment 3

[0030] solvent Adiponitrile Dimethyl sulfoxide N, N-Dimethylformamide Product yield (%) 61 47 52

[0031] Replace acetonitrile with other solvents, other conditions are the same as Example 1, and the experimental results are shown in the table above.

[0032] As can be seen from the above table, the reaction can be carried out in polar solvents, among which the best effect is in acetonitrile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com