Ink composition and method for producing dyed polyamide-based fiber

An ink composition, polyamide technology, applied in the direction of dyeing method, copying/marking method, ink, etc., to achieve the effects of excellent ejection stability, good fixation, and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

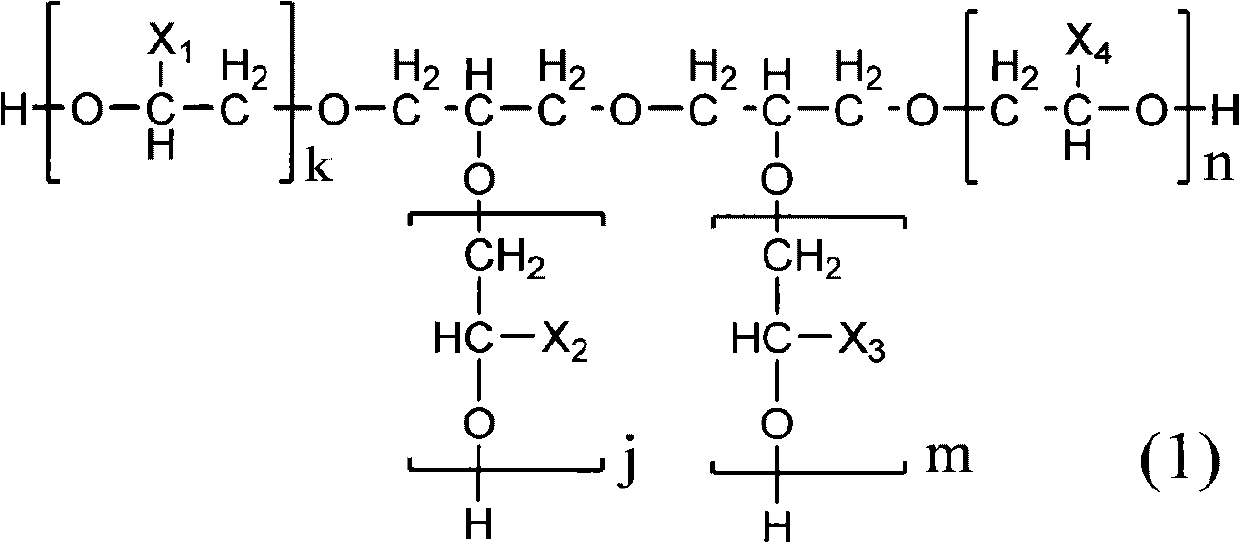

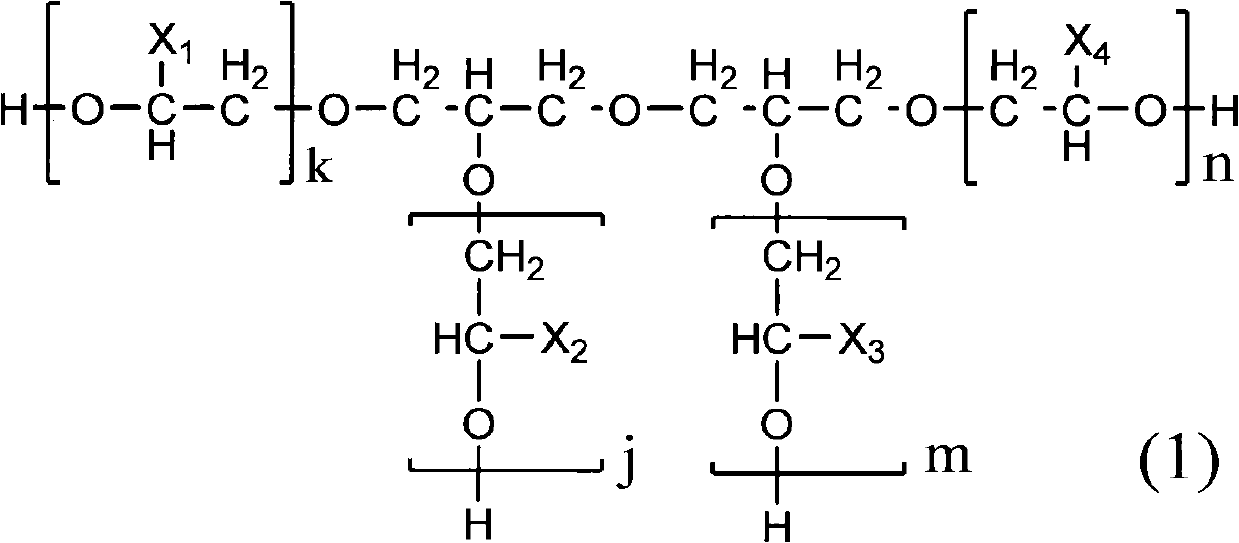

Method used

Image

Examples

preparation example Construction

[0098] The water used for the preparation of the ink is usually preferably purified water.

[0099] Water or the like that has not been purified contains metal ions such as calcium ions and magnesium ions. Therefore, when such water or the like is used in the preparation of the ink composition, a trace amount of the metal ions or the like may be mixed into the ink composition. Therefore, it is preferable to use water with less inorganic impurities, such as distilled water or ion-exchanged water, to prepare the ink composition of the present invention.

[0100] Hereinafter, in this specification, for the sake of convenience, the inorganic salts mixed in the aforementioned dyes and the metal ions derived from the water used in the preparation of the aforementioned inks are collectively referred to as "inorganic impurities".

[0101] These inorganic impurities not only significantly deteriorate the solubility of the dye in the water-based ink solvent and the storage stability of ...

Embodiment 1~10

[0183] The components described in each of the following Examples were mixed and stirred for about 1 hour until the solid content was dissolved, whereby each ink composition was obtained. After that, it was filtered using a 0.45 μm membrane filter (trade name: cellulose acetate filter paper, manufactured by Advantec Toyo Co., Ltd.), thereby preparing an ink for the test. The preparation of the ink is respectively referred to as Examples 1-10.

[0184] In addition, each dye used as a pigment in each ink is manufactured by Nippon Kayaku Co., Ltd. The terms "acid", "direct" and "reactive" described immediately after "C.I." in each dye are known to mean "acid dye", "direct dye" and "reactive dye", respectively.

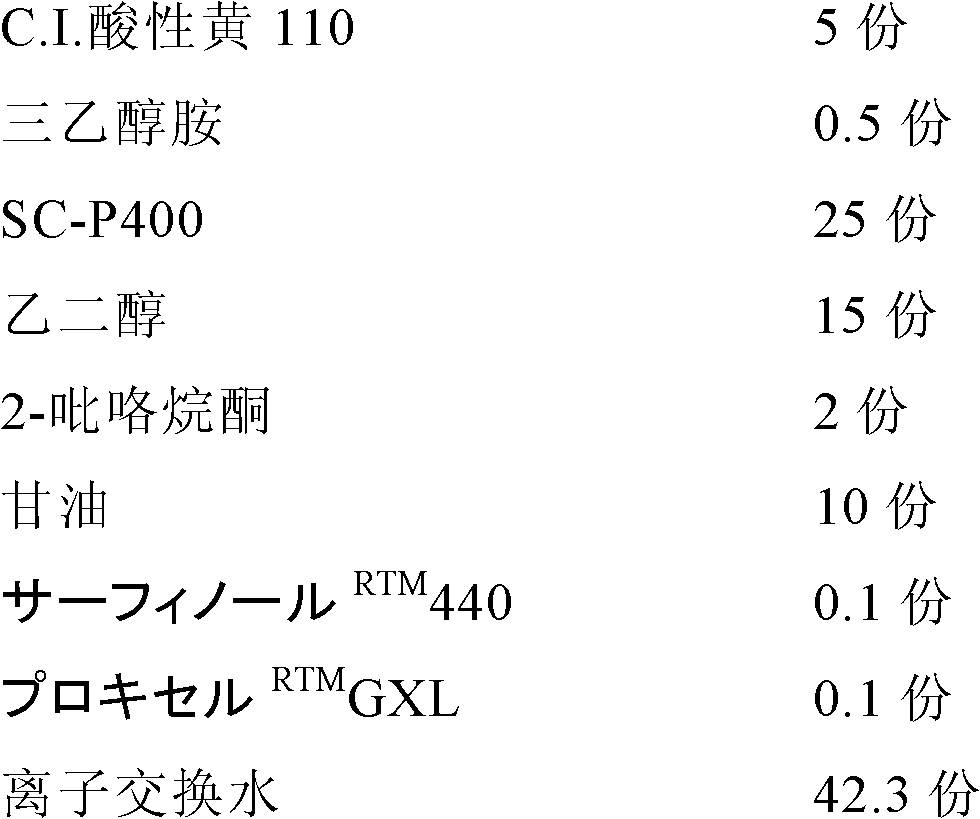

Embodiment 1

[0186] [Example 1 (yellow ink)]

[0187]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com