Method for drawing grin lens fiber

A lens fiber and prefabricated technology, applied in glass fiber drawing devices, lenses, glass fiber products, etc., can solve the problems of loss, disconnection, long time, etc., and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

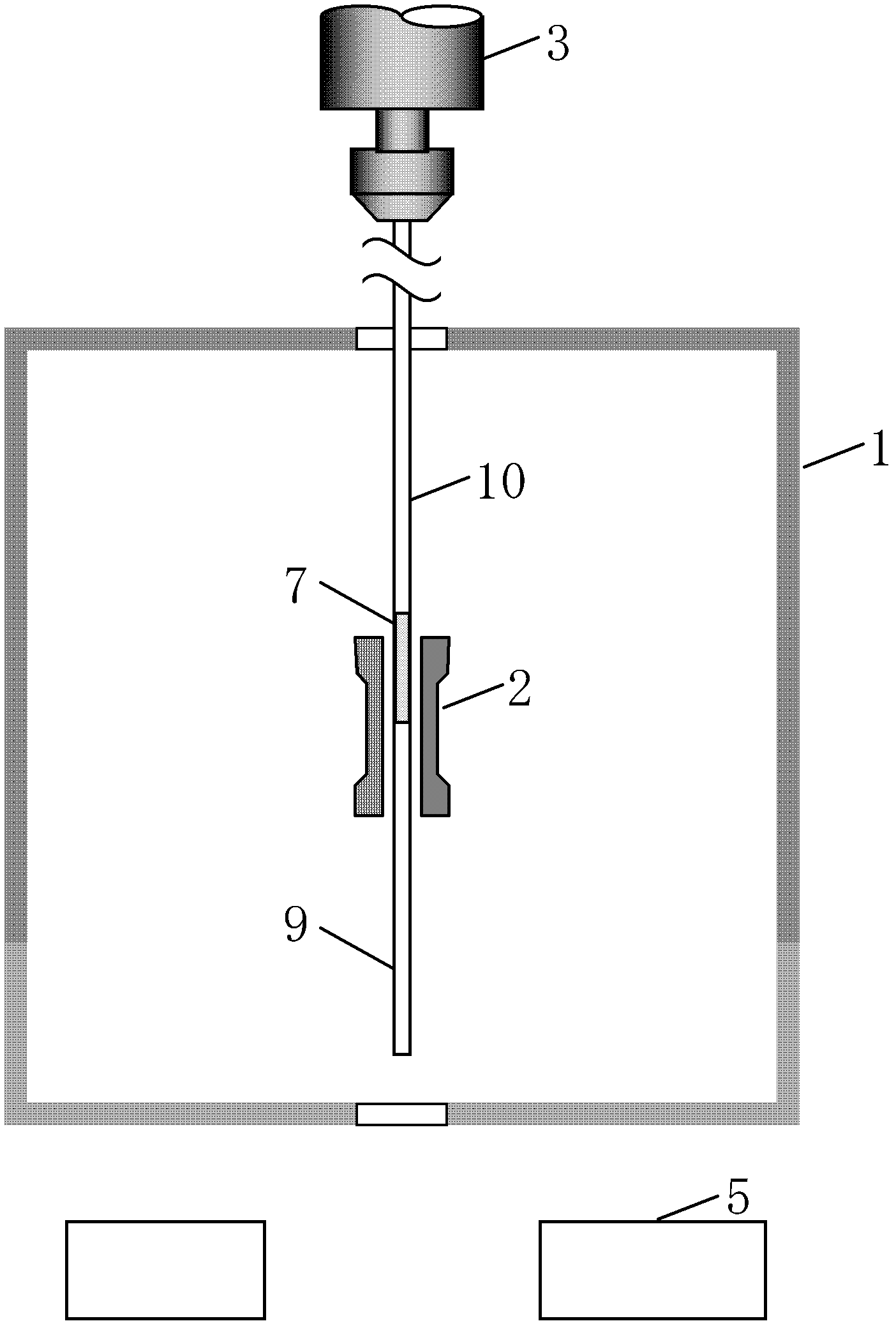

[0042] figure 1 with 4 Shown is the GRIN lens fiber drawing device. The wire drawing device has a heating furnace 1, a heater 2, a lifting device 3, a reel 4, a wire diameter measuring instrument 5 and an automatic control device 6.

[0043] The heating furnace 1 is an ultra-high temperature vertical tubular furnace capable of heating up to 2100°C.

[0044] The reel 4 has a transverse movement mechanism to prevent the fibers from overlapping. In this embodiment, the drawn GRIN lens fiber is directly wound on the reel 4, and the drawing speed is controlled by controlling the reel rotation speed. You can also set a guide wheel in front of the reel to control the drawing speed by controlling the speed of the guide wheel.

[0045] A lifting device 3 is provided above the heating furnace 1 to hold and lift the preform 7.

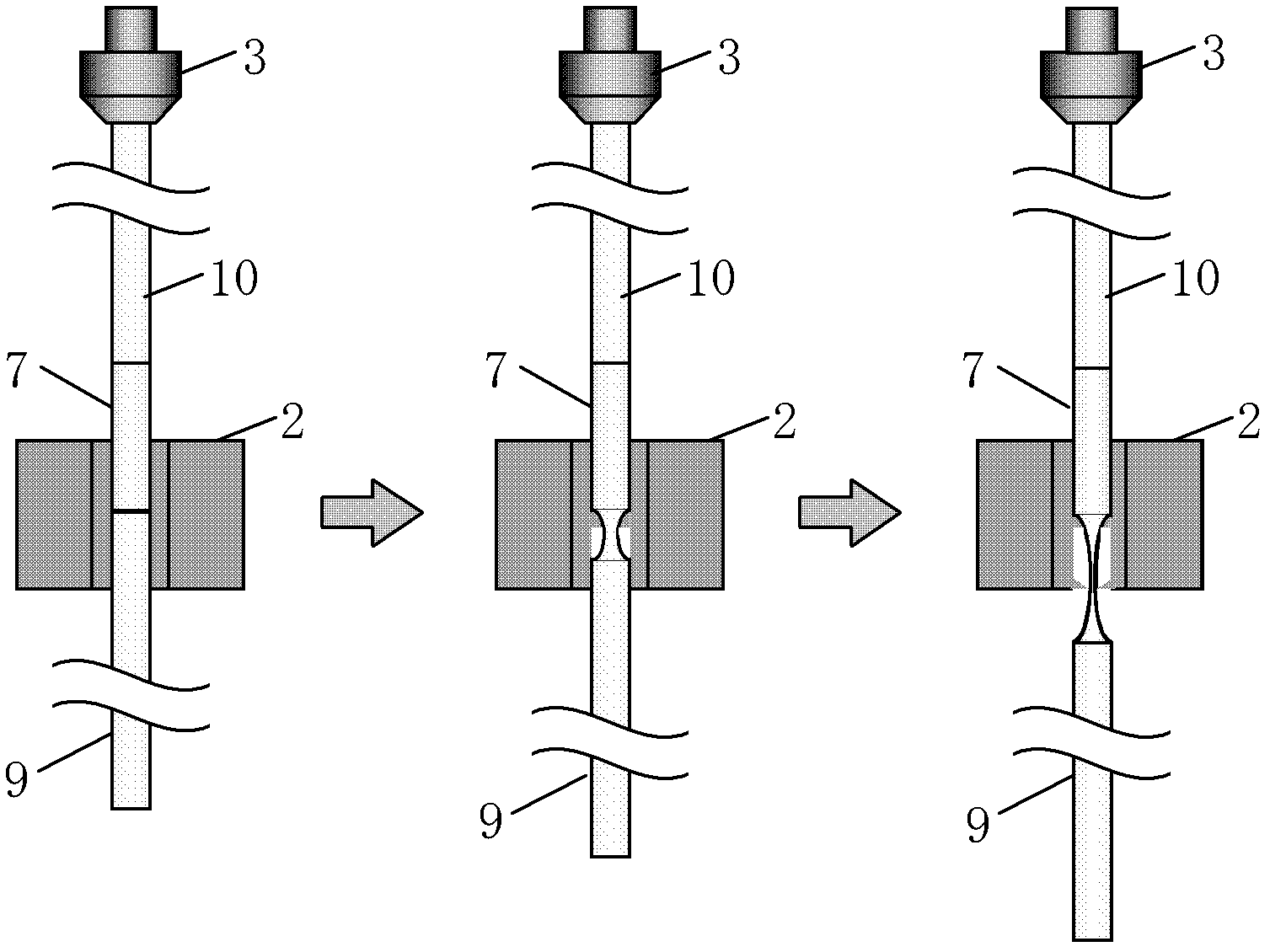

[0046] A quartz rod 10 is welded to one end (upper end) of the preform 7, and a weight 9 is welded to the other end (lower end). The quartz rod 10 is a rod-shaped ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com