Preparation method of cathode material for high-power alkaline manganese battery

A technology of alkaline manganese batteries and positive electrode materials, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory performance, small discharge capacity of medium and high voltage sections, and low load voltage, so as to improve deep discharge capacity, The effects of stable lattice structure and increased discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

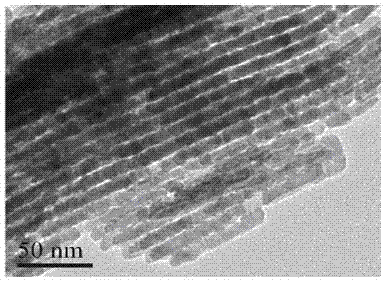

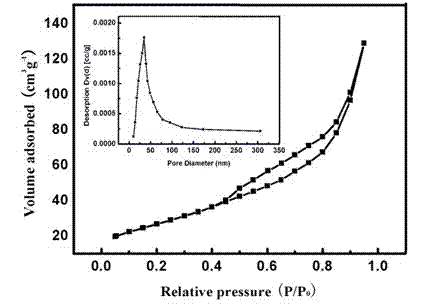

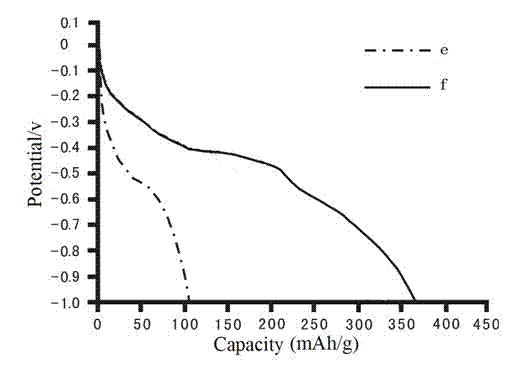

[0021] Embodiment 1: adopt the preparation method of the present invention to prepare a kind of positive electrode material that is used for high-power alkaline manganese battery, take manganese nitrate as raw material, take mesoporous silica as template agent, take bismuth salt as dopant, according to manganese Salt solution, bismuth salt solution and the ratio of the mass parts of template agent is 1: (0.01~0.5): (2~10), weigh 2 parts of manganese nitrate solution, add 50 parts of distilled water, add 1 part of bismuth nitrate, mix After uniformity, add 20 parts of mesoporous silica template, stir evenly, make the manganese salt adhere to the template by liquid phase impregnation method, and then dry; calcinate the dried mixture at 100°C for 8 hours (hours) to oxidize the manganese salt The reduction reaction produces bismuth-doped mesoporous manganese dioxide, and a dark brown substance is obtained. According to the mass fraction of bismuth-doped mesoporous manganese dioxid...

Embodiment 2

[0023] Embodiment 2: Adopt the preparation method of the present invention to prepare a kind of positive electrode material for high-power alkaline manganese battery, take 1 part of manganese chloride solution according to the ratio of mass and number, add 50 parts of distilled water, add 0.1 part of bismuth nitrate solution, mix well Finally, add 8 parts of mesoporous silica template, stir evenly, make manganese salt adhere to the template by liquid phase impregnation method, and then dry; calcinate the dried mixture at 1000°C for 2 hours to obtain a dark brown substance, according to the method of bismuth-doped mesoporous The mass fraction of manganese dioxide and sodium hydroxide solution is 1: (10~100) ratio, 10 parts of 1mol / L sodium hydroxide solution is used to remove the silicon template, and the obtained black precipitate is separated by filtration and washed with distilled water. , after drying at a temperature of 80°C, a bismuth-doped mesoporous manganese dioxide ele...

Embodiment 3

[0024] Embodiment 3: adopt the preparation method of the present invention to prepare a kind of positive electrode material for high-power alkaline manganese battery, take 2 parts of manganese sulfate solution according to the ratio of mass and number, add 50 parts of distilled water, add bismuth nitrate 0.5 solution, after mixing uniformly, Add 8 parts of mesoporous silica template, stir evenly, attach the manganese salt to the template by liquid phase impregnation method, and then dry it; calcinate the dried mixture at 800°C for 2 hours to obtain a dark brown substance. The mass fraction of manganese oxide and sodium hydroxide solution is 1: (10~100), use 50 parts of 0.5mol / L sodium hydroxide solution to remove the silicon template, filter and separate the obtained black precipitate, and wash the precipitate with distilled water , after drying at a temperature of 80°C, a bismuth-doped mesoporous manganese dioxide electrode material product was obtained, with a discharge capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com