Low temperature optical system support device with high heat insulation efficiency and small thermal stress influence

A technology of thermal insulation efficiency and optical system, applied in the field of low-temperature optics of aerospace optical remote sensors, can solve the problems of low-temperature optical system deformation, affecting imaging quality, difficult to achieve support, etc., and meeting the requirements of improving thermal insulation efficiency, ensuring accuracy, and ensuring accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

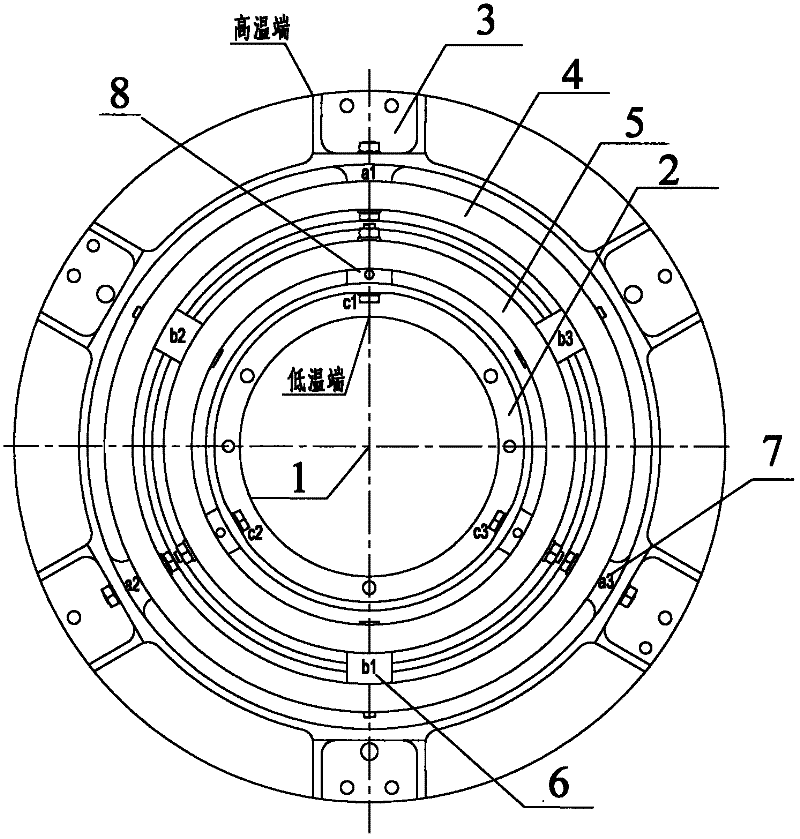

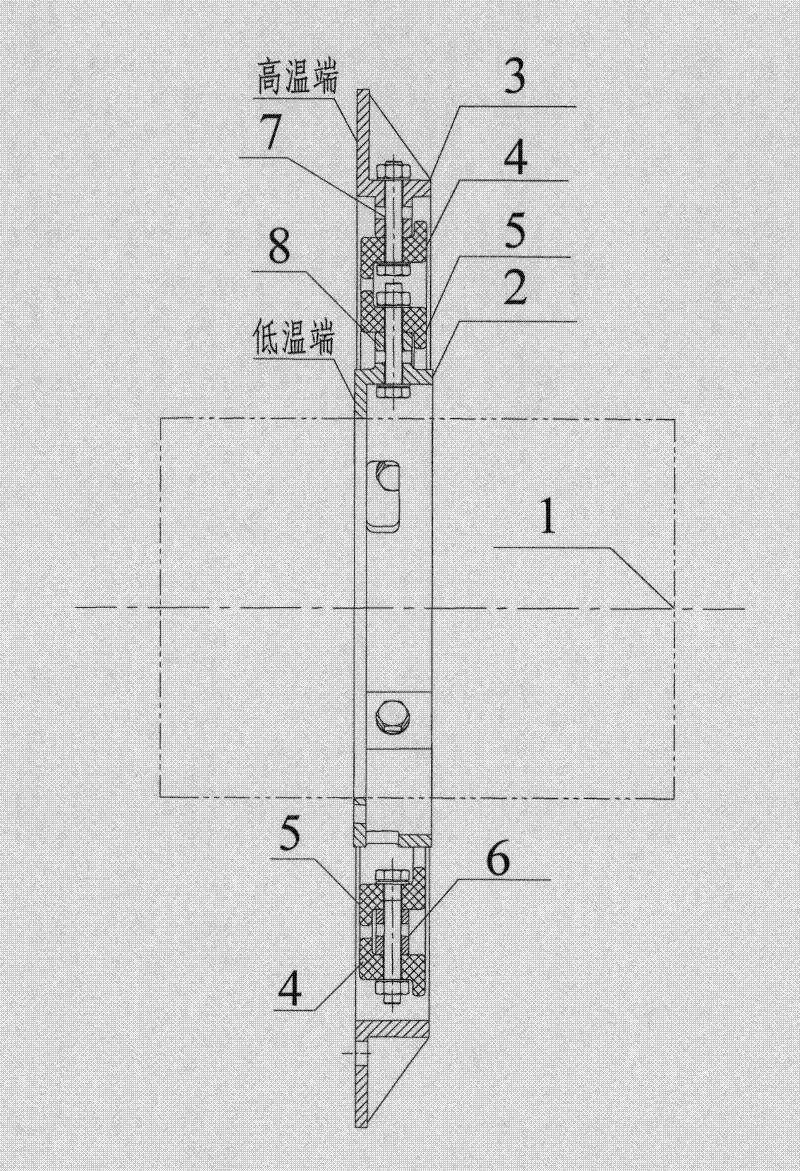

[0020] Such as figure 1 Shown is a schematic diagram of the structure of the low-temperature optical system supporting device of the present invention, figure 2 Shown is a cross-sectional view of the structure of the low-temperature optical system support device of the present invention. It can be seen from the figure that the support device includes a support inner ring 2, a support outer ring 3, a first heat insulation ring 4, a second heat insulation ring 5, and three transition blocks 6 , three first support blocks 7 and three second support blocks 8, wherein the optical system 1 is placed inside the support inner ring 2 and connected to the support inner ring 2, and the support inner ring 2 and the second heat insulation ring 5 pass through the uniform distribution Three second support blocks 8 ( figure 1 c1, c2, c3) in the fixed connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com