Metal low-temperature film storage tank for liquid hydrogen storage

A storage tank and liquid hydrogen technology, applied in the field of refrigerated liquefied gas-liquid hydrogen low-temperature storage devices, can solve the problems of hydrogen volatilization, transportation and storage limitations, etc., to reduce evaporation rate, reduce requirements and construction requirements, and ensure storage. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

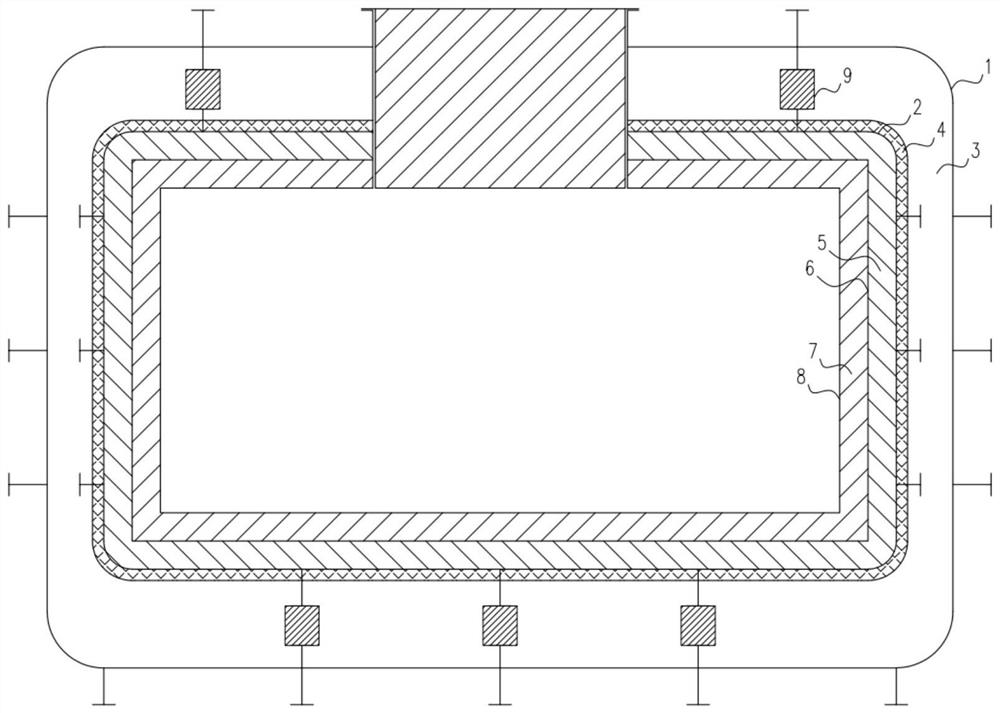

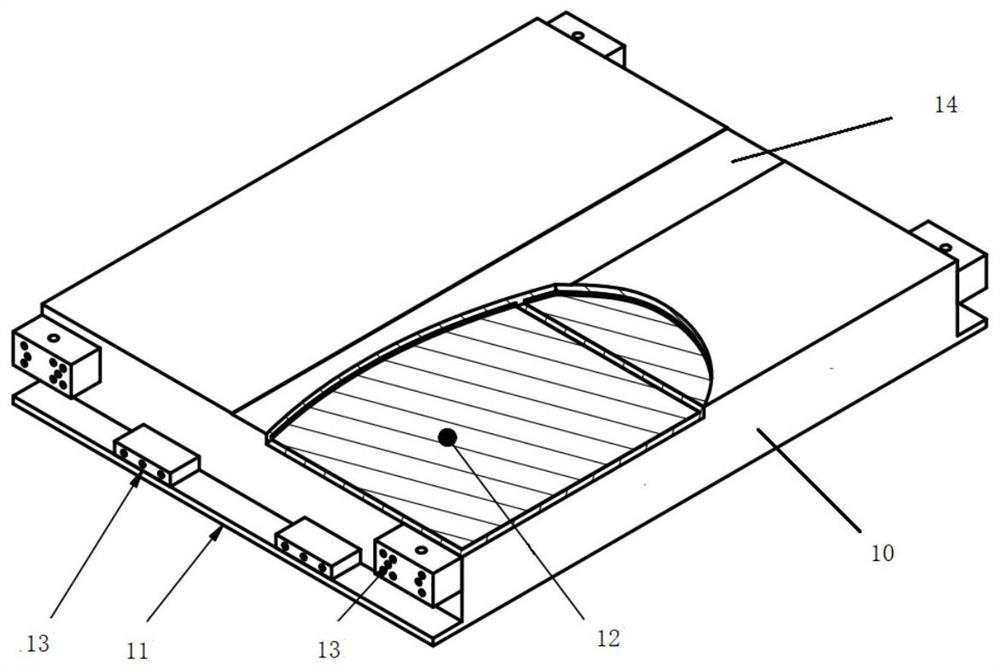

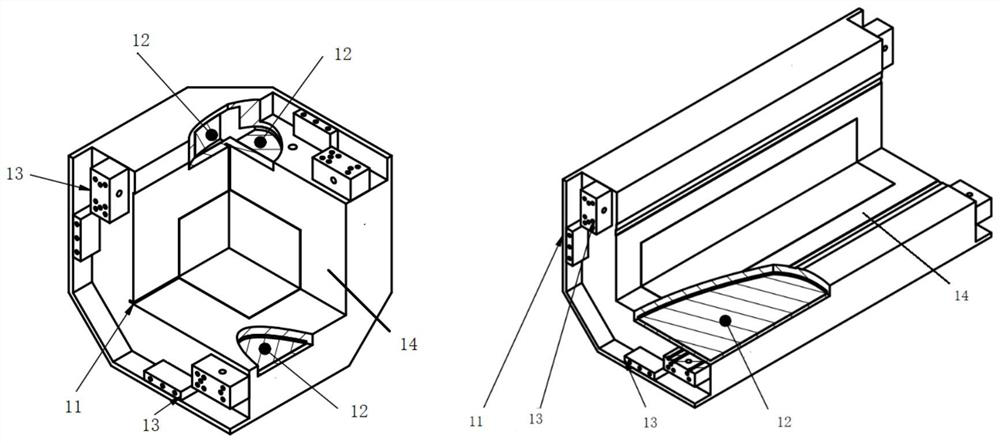

[0034] see Figure 1-6 , the invention is based on two layers of metal film and high vacuum insulation tank as the design basis, realizes a set of independent film shielding layer liquid storage system, and uses high vacuum insulation to improve the insulation and cold preservation performance of traditional film storage tanks, further Reduce the evaporation rate and increase the storage time of liquid cargo hydrogen in the storage tank; use a thin film shielding layer to hold liquid, further reducing the requirements for the material and construction of the inner and outer tanks; double-layer shielding and three-layer protection of the inner tank improve the hydrogen storage. Safety performance, the flexibility of the film ensures the integrity of the shielding in case of an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com