Heat treatment system used for producing ultrahigh strength steel

A heat treatment system and ultra-high-strength steel technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as low temperature, failure to meet carbon distribution process requirements, high local temperature, etc., to achieve uniform furnace temperature and good plate shape , the effect of uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

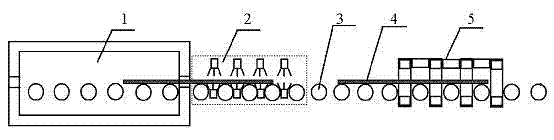

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

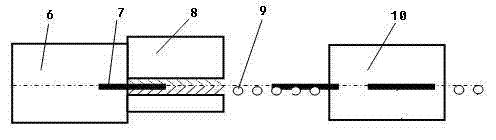

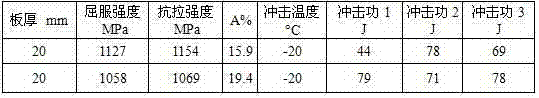

[0023] Such as figure 2 As shown, the equipment layout of the steel plate Q+P heat treatment system of the present invention is as follows: roller hearth quenching furnace 6, steel plate 7, roller quenching machine 8, transport roller table 9, open fire roller hearth tempering furnace 10. The roller hearth quenching furnace adopts the radiant tube non-oxidation roller hearth furnace. Before entering the furnace, the steel plate is shot peened first. Because of the N2 protection in the furnace, the surface of the steel plate is free from oxidation and scratches, so as to meet the high surface quality requirements; The type quenching machine is to adjust the roll gap between the upper frame roll and the lower frame roll to a plate thickness of +2~3mm, and the steel plate moves between the rolls. Quenching in the front movement; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com