Totally-enclosed split type powder metallurgy soft magnetic tank

A powder metallurgy and assembled technology, applied in the manufacture of inductors/transformers/magnets, preventing/reducing unwanted electric/magnetic influences, electrical components, etc., can solve problems such as the inability to guarantee electromagnetic compatibility and magnetic flux leakage. Achieve the effect of saving equipment input cost, saving material cost, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

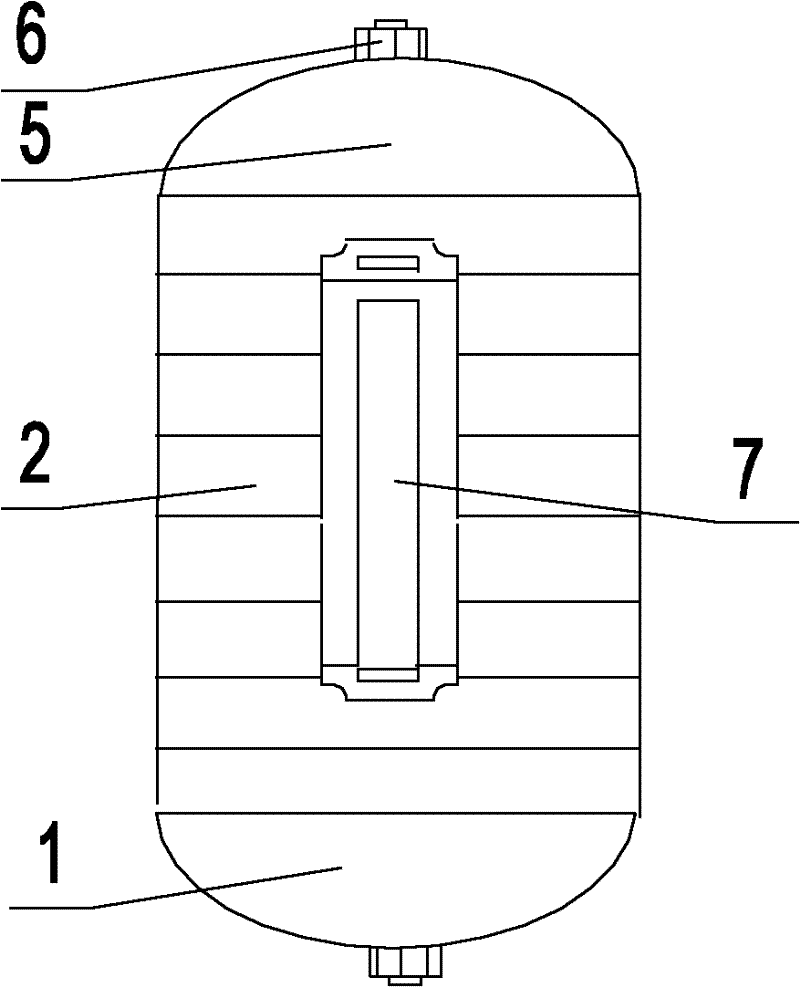

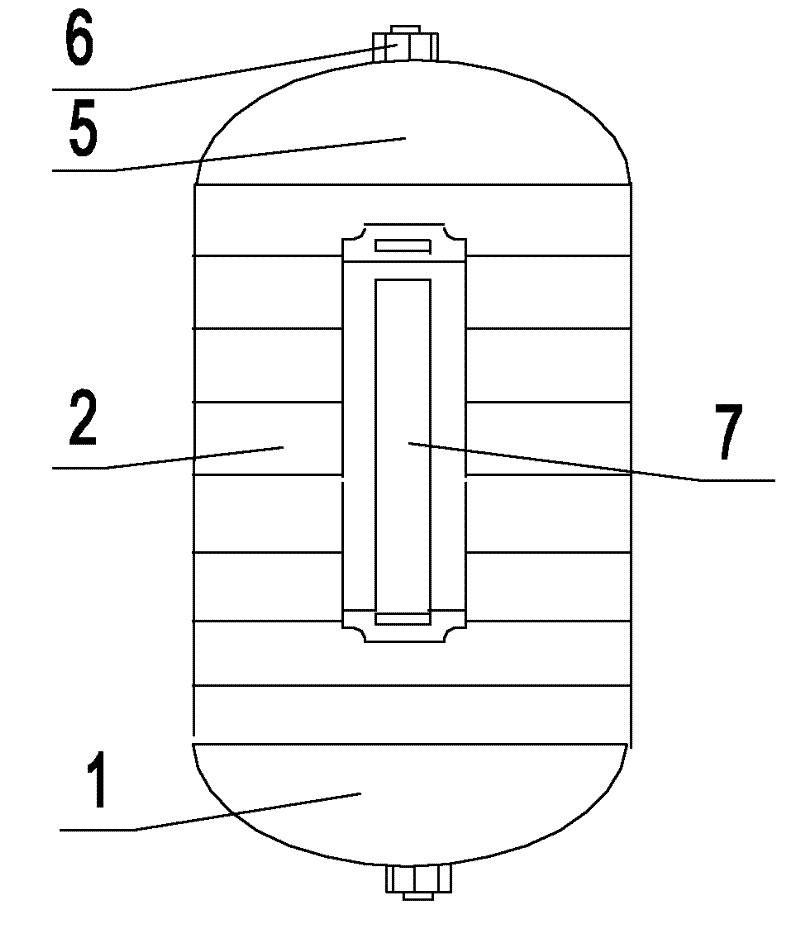

[0011] The present invention uses soft magnetic materials to make three parts in ring shape, semi-disc shape and column shape, and adopts an assembling method to bond the above parts into a tank shape with magnetically conductive glue. The ring-shaped parts are used to form the outer shell, the cylindrical parts are used to form the inner core, and the semi-disc-shaped parts form the upper and lower bottom plates of the product. The shell of the tank is not only the protective shell of the product but also the magnetic circuit, which forms the product shell together with the internal magnetic column and the upper and lower bottom plates, thus forming a closed magnetic circuit. The tank is a fully enclosed tank except for the wire outlet, which minimizes the possibility of magnetic flux leakage.

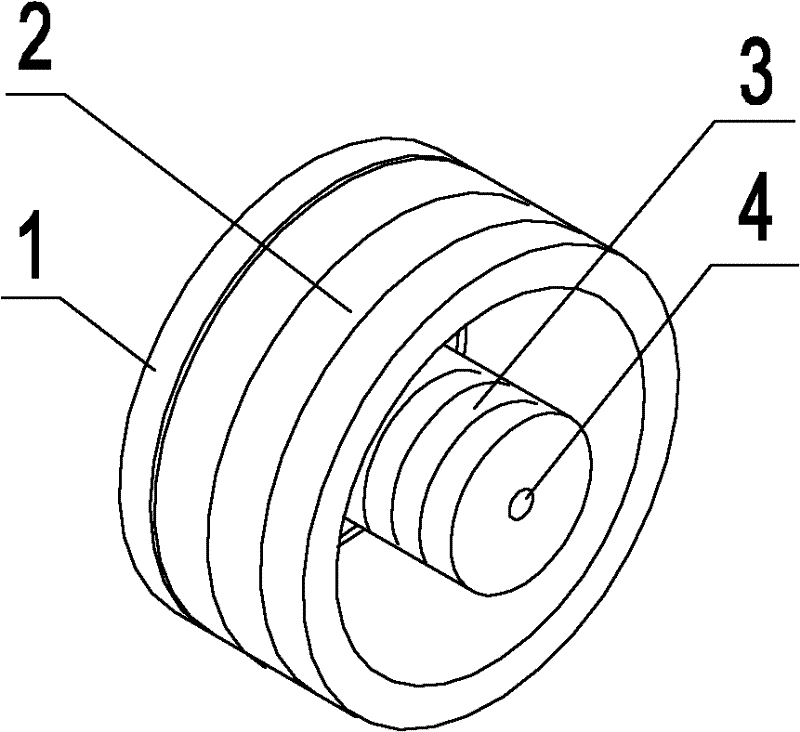

[0012] See the specific structure figure 1 , 2 shown. Depend on figure 1 , 2 It can be seen that the magnetic tank body is composed of a magnetic core 3, a magnetic ring shieldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com