Tertiary optical detection machine for IC (integrated circuit) strips and operating method thereof

A material strip and optical inspection technology, which is applied in the direction of analyzing materials, conveyor objects, and optical testing for flaws/defects, etc., can solve the problems of inspection efficiency and quality that manual inspection has no obvious advantages, low work efficiency, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

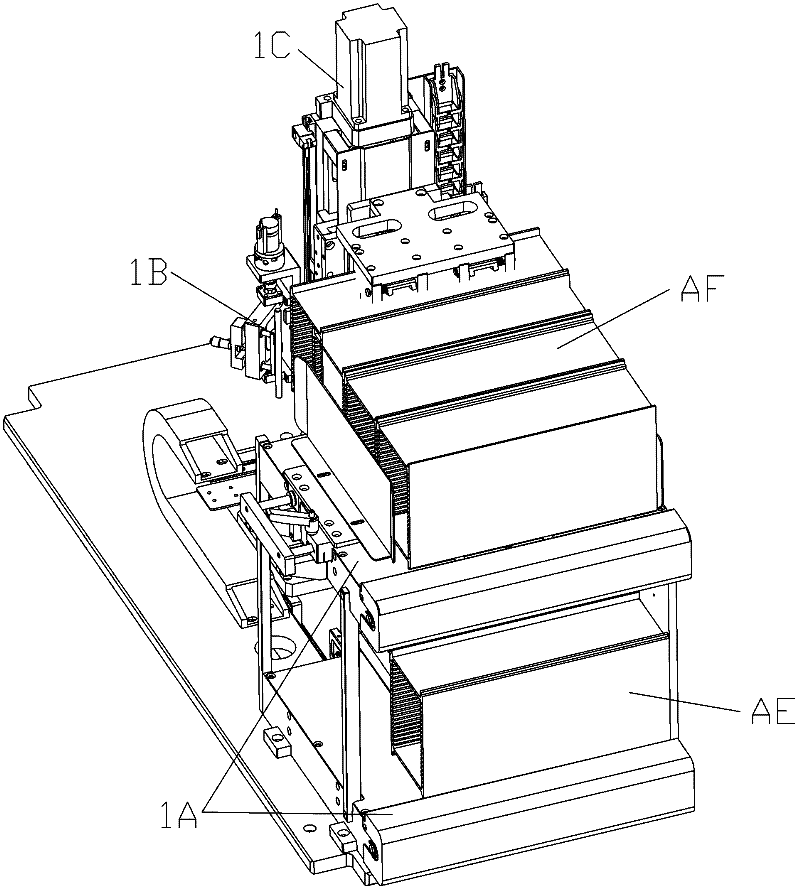

[0037] Commonly used material boxes include trough-type material boxes and stacked-type material boxes. There are slots for inserting strips arranged from top to bottom in the trough-type material boxes. The side and the right side have left and right openings respectively for inserting and extracting strips. The material box that the present invention relates to is above-mentioned trough type material box, and the material box that is equipped with the material strip that waits for light inspection and light inspection is respectively called upper material box and lower material box, in addition, as image 3 As shown, the full-loaded material box waiting for light inspection or the light-inspected strip is called the material box AF, and the empty material box is called the empty material box AE.

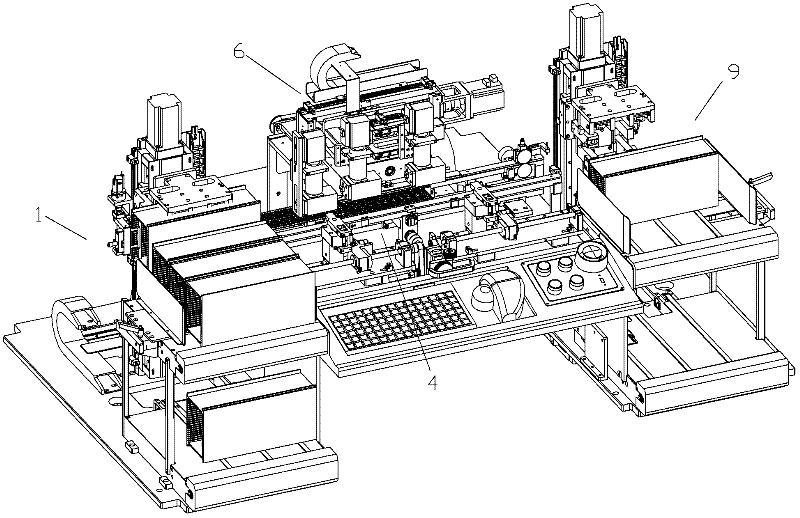

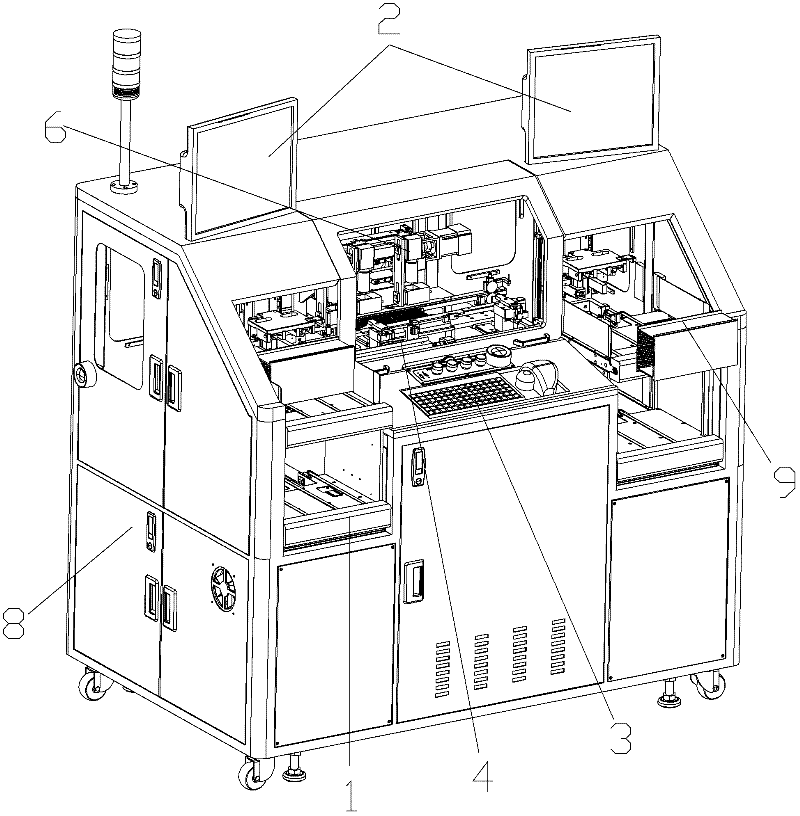

[0038] The three-time optical inspection machine for IC strips of the present invention mainly includes such as figure 1 with 2 Shown strip conveying system 4 and photodetection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com