Method for distillation synthesis of biodiesel by acid-catalyzed reaction

A technology of reactive distillation and synthetic biology, which is applied in the fields of biofuel, fatty acid esterification, petroleum industry, etc., can solve problems such as limiting the scope of use, and achieve the effects of increasing the scope of application, reducing energy consumption, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

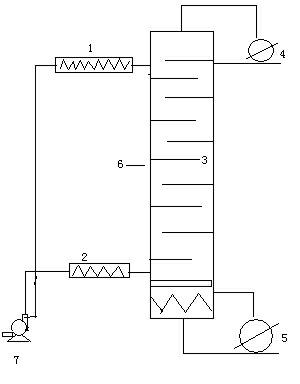

Image

Examples

Embodiment 1

[0026] The oil raw material is refined fatty acid with an acid value of 196mgKOH / g. After heating and melting, it is mixed with sulfuric acid accounting for 1% of the weight of the oil raw material and methanol accounting for 5% of the weight of the oil raw material. , while the remaining methanol is preheated to 70°C and enters the bottom of the reactor, and is heated to overboiling (90-100°C) by the bottom heater to ensure that the methanol vapor can rise to the top of the tower. The methanol flow rate is controlled to 22.5g / h, and the oil flow rate is 150g / h (including 7.5g methanol and 1.5g sulfuric acid), most of the water and catalyst sulfuric acid produced by the reaction are separated from the bottom of the tower, and a small amount of unreacted methanol and water are separated from the top of the tower, and the methanol is recycled after rectification. The crude methyl ester of the semi-finished product whose acid value is less than 2mgKOH / g is sent to the post-treatme...

Embodiment 2

[0028] The raw material of oil is waste oil with an acid value of 78mgKOH / g. After vacuum dehydration, it is mixed with methanol accounting for 4% of the weight of the oil raw material and sulfuric acid accounting for 1.5% of the weight of the oil raw material, and then enters the preheater, and is heated at 85-90°C and enters the upper part of the reactor. The remaining methanol is preheated to 70°C and enters the bottom of the reactor, and is further heated to overboiling by the bottom heater to ensure that the methanol vapor can rise to the top of the tower. Control the flow rate of methanol to 24g / h, and the flow rate of oil to 150g / h (including 6g methanol and 2.25g sulfuric acid); the glycerin, water, catalyst sulfuric acid and a small amount of methanol generated by the reaction are separated from the bottom of the tower, and a small amount of methanol and water are separated from the top of the tower , Methanol is recovered for recycling after rectification. The acid v...

Embodiment 3

[0030] The oil raw material is vegetable oil with an acid value less than 2mgKOH / g, mixed with 4% methanol and 2% sulfuric acid by weight of the oil raw material, then enters the preheater, heats to 85-90°C and enters the upper part of the reactor, and the remaining methanol is preheated. It is heated to 70°C and enters the bottom of the reactor, and is further heated to overboiling by the bottom heater to ensure that the methanol vapor can rise to the top of the tower. Control the flow rate of methanol to 24g / h, and the flow rate of oil to 150g / h (including 6g methanol and 3g sulfuric acid); the glycerin, catalyst sulfuric acid and a small amount of methanol generated by the reaction are separated from the bottom of the tower, and the methanol at the top of the tower can be directly returned to the cycle. The semi-finished product is sent to post-treatment after testing that the residual glycerin is less than 0.5%, and the biodiesel product that meets the standard is obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com