Preparation method for multilayer copper/molybdenum structure composite plate

A composite plate and copper plate technology, applied in the direction of metal rolling, can solve the problems of low tensile strength, poor interface bonding, low yield strength, etc., and achieve the effect of increasing bonding strength, high yield, and improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

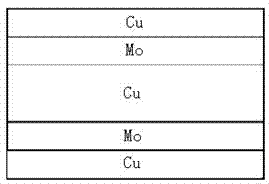

[0027] Embodiment 1: the preparation of five-layer copper / molybdenum composite board

[0028] see figure 1 As shown in Figure 3(a), this example presents a method for preparing a five-layer copper / molybdenum composite board. The structure of the fabricated copper / molybdenum five-layer composite board is copper / molybdenum / copper / molybdenum / copper, specifically Follow these steps to implement:

[0029] 1. Preparation of molybdenum plate and copper plate

[0030] Use industrial pure molybdenum blanks at 1000°C to 1350°C to roll them into molybdenum plates with a thickness of 0.5mm to 6mm, and treat them for 1.5 hours according to the conventional heat treatment process conditions, and then cool with the furnace;

[0031] Take the industrial pure copper plate, the thickness of the copper plate is: 1.0 ~ 10.0mm, put it in the annealing furnace, anneal at 600 ℃ for 1h ~ 1.5h, and cool with the furnace;

[0032] Grinding the surface of the above-mentioned molybdenum plate and copp...

Embodiment 2

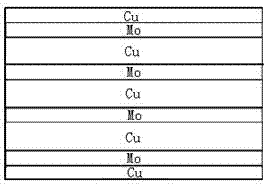

[0039]Embodiment 2: the preparation of nine-layer copper / molybdenum composite board

[0040] Prepare according to the five-layer copper / molybdenum / copper / molybdenum / copper multilayer structure composite board prepared in Example 1, repeat the operation from the grinding operation in Step 1 to Step 6 in Example 1, and carry out the accumulation of 3 to 6 passes Composite rolling, and the heat treatment of step 7 is carried out to obtain a composite plate with nine layers of copper / molybdenum / copper / molybdenum / copper / molybdenum / copper / molybdenum / copper structure (the thickness ratio of copper plate and molybdenum plate is 1:1:2: 1:2:1:2:1:1), as shown in Figure 3(b).

[0041] After testing, the tensile strength of the copper / molybdenum composite board prepared in the above embodiment is 390-620 MPa, the yield strength is 200-300 MPa, and the elongation is 25%-30%. Subsequent selective rolling or shearing can be done according to the required size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com