Method for pre-dressing low-grade single molybdenum ore body molybdenite in advance

A low-grade molybdenite technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of high grinding costs and increased consumption of flotation agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Taking a concentrator with a daily processing capacity of 10,000 tons and an ore grade of 0.07% as an example, a comparative analysis of the economic benefits of production using general-purpose technology and patented technology is shown in Table 1.

[0017] Table 1 Economic benefit comparison table

[0018] serial number

[0019] It can be seen from Table 1 that the annual economic benefit of this patented technology can reach 9.03 million yuan compared with the conventional general-purpose technology. The implementation of this patented technology only needs to add a section of screening operation to the original process, which is low in investment and easy to implement. The payback period is only 1.06 months.

Embodiment 2

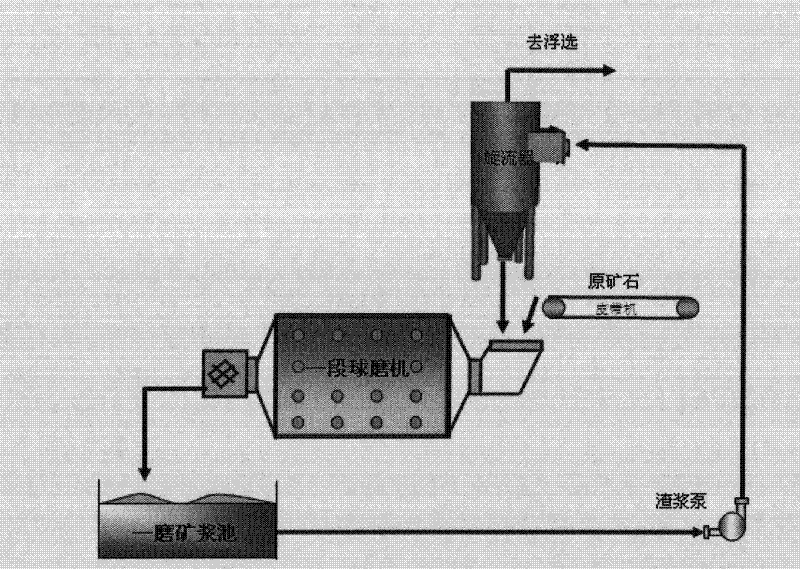

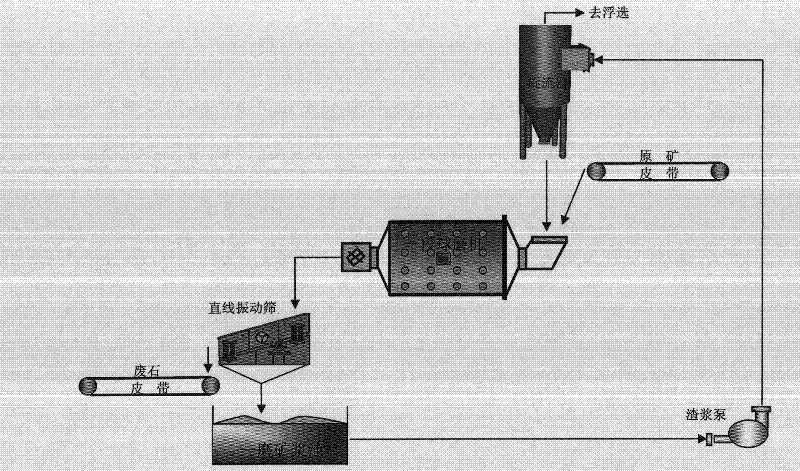

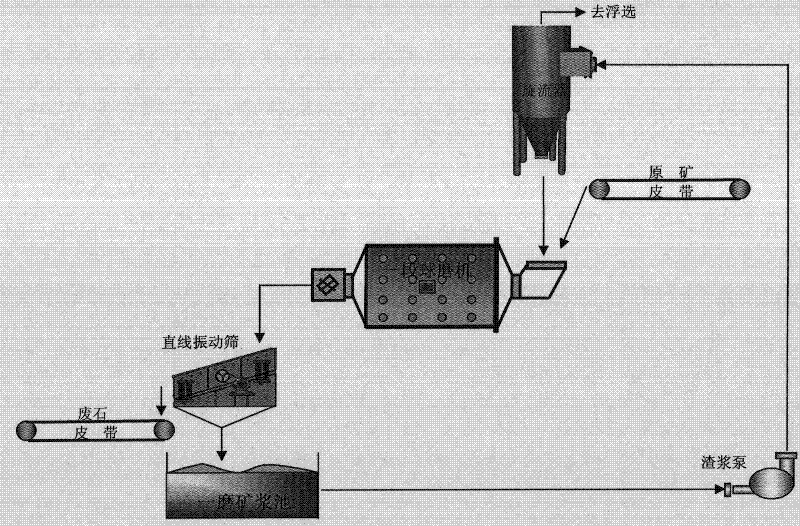

[0021] The original ore grade of a tuff-type molybdenum ore is Mo0.054%, and the original process flow of on-site grinding and grading is shown in Figure 1. After the raw ore enters the ball mill, the ground product is transported to the classifier (hydrocyclone) by the pump, the underflow of the classifier returns to the ball mill, and the overflow of the classifier enters the subsequent sorting operation. For the preferential dissociation characteristics of molybdenite minerals in the molybdenum ore grinding process, on the basis of the process flow shown in Figure 1, the pre-selection process of the present invention shown in Figure 2 is adopted, and a linear vibrating screen is added behind the ball mill. The material is discarded as waste sand, and is transported to the waste sand storage yard by the belt, the underscreen material is transported to the classifier by the pump, the underflow of the classifier returns to the ball mill, and the overflow of the classifier enter...

Embodiment 3

[0028] The molybdenum grade of a tuff-type molybdenum ore is 0.081%.

[0029] Feed concentration of high-frequency vibrating sieve: 43%, mesh size of high-frequency vibrating sieve: 8mm.

[0030] Adopt the pre-selection process index of the present invention to see Table 3.

[0031] Table 3 Pre-selection results of high-frequency vibrating screen (8mm) for ball mill discharge

[0032] product name

Yield / %

Grade / %

Recovery rate / %

+8mm

8.36

0.025

2.58

-8mm

91.64

0.086

97.42

100.00

0.081

100.00

[0033] Adopt the pre-selection process of the present invention, adopt 8mm sieve hole vibrating screen, the Mo grade of under-sieve particle size (-8mm) is raised to 0.086% by 0.081%, waste sand (+8mm) grade is reduced to 0.025%, and throwing away rate reaches 8.36% %, the loss rate of molybdenum in waste sand is 2.58%. The above results show that a large amount...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com