Concatenated multilevel inverter circuit capable of realizing energy feedback and control method

A technology of cascading multi-level and inverter circuits, which is applied in the field of power electronics, can solve problems such as increased cost, increased complexity of system control, and adverse effects on system reliability, and achieves reduced number of uses, simplified design requirements, and high economy value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific implementation.

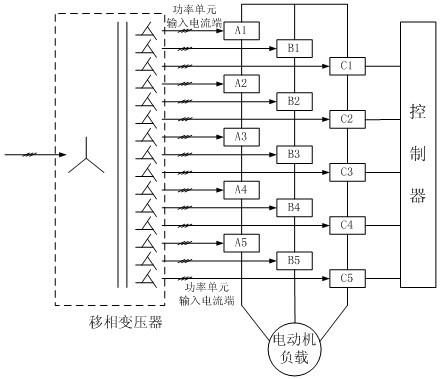

[0024] figure 1 It is the topological structure diagram of the traditional cascaded high-voltage inverter. The traditional cascaded high-voltage inverter is composed of a phase-shifting transformer, a power unit and a controller. Each power unit A1, A2, A3, A4, A5, B1, B2, B3, B4, B5, C1, C2, C3, C4, C5 provides a three-phase power supply, and the output voltage of each power unit is superimposed in series to form a three-phase power supply. phase sine wave to supply power to the motor load.

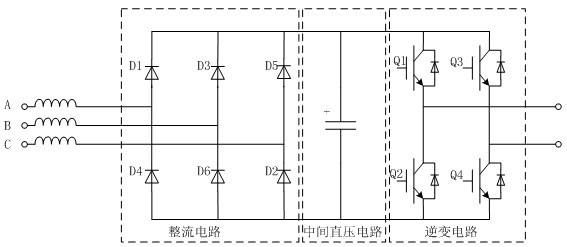

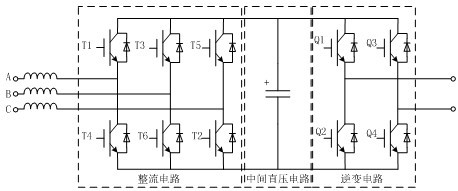

[0025] The power unit in the prior art includes a power unit based on a three-phase uncontrolled rectifier circuit and a power unit based on a three-phase PWM rectifier circuit, respectively as figure 2 and image 3 As shown, the power unit based on the three-phase uncontrolled rectifier circuit and the power unit based on the three-phase PWM rect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com