U-shaped switched reluctance motor

A switched reluctance and motor technology, applied in the field of motors, can solve problems such as steep price rise, demagnetization, reduction of motor power and efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

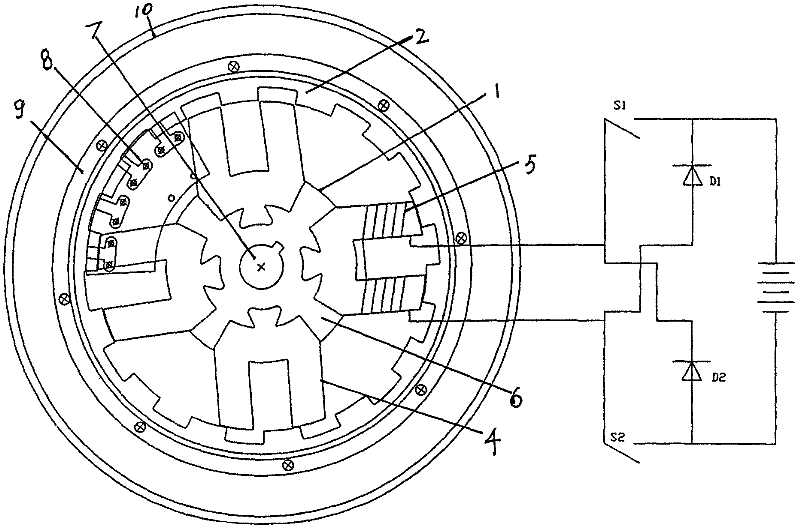

[0015] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0016] see Figure 1-Figure 8 , a U-shaped switched reluctance motor, which includes a stator 1, a rotor 2 and a side cover 3, the opposite salient poles in the stator are respectively provided with windings 5, the windings 5 of radially adjacent poles are connected in series to form a phase, and the two windings 5 each Connect switch S1, diode D2 and switch S2, diode D1 to connect the positive and negative poles of the power supply respectively. The stator 1 is composed of a magnetic spacer 6, a central shaft 7, a position plate 8 and a U-shaped salient pole 4. The central shaft 7 is embedded in the center of the magnetic spacer 6. , The position plate 8 is installed on the spacer magnet 6, four sets of U-shaped salient poles 4 are evenly embedded in the spacer magnet 6, and the U-shaped salient poles 4 have opposite salient poles.

[0017] see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com