Testing method for monitoring automotive ABS (Antilock Braking System) performance based on hub type intelligent sensing self-adaptive variable-frequency sampling

A technology of intelligent sensing and frequency conversion sampling, which is applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc. It can solve the problem of increasing the computational burden of the processor, wasting energy consumption of wireless communication, and not adopting adaptive frequency conversion sampling, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose, technical solutions and advantages of the present invention clearer, the implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings:

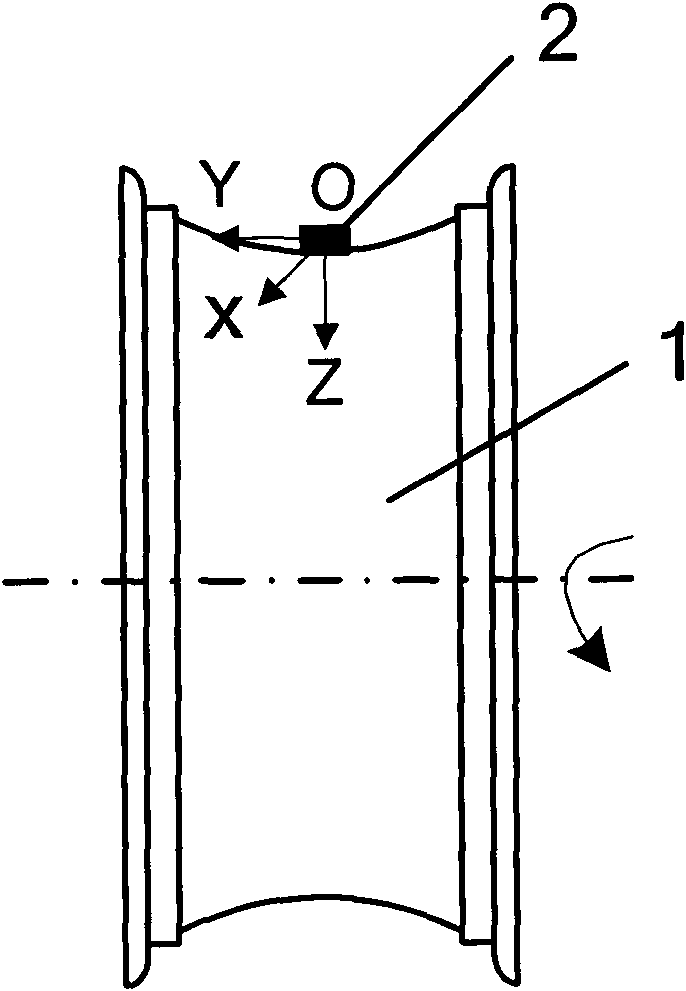

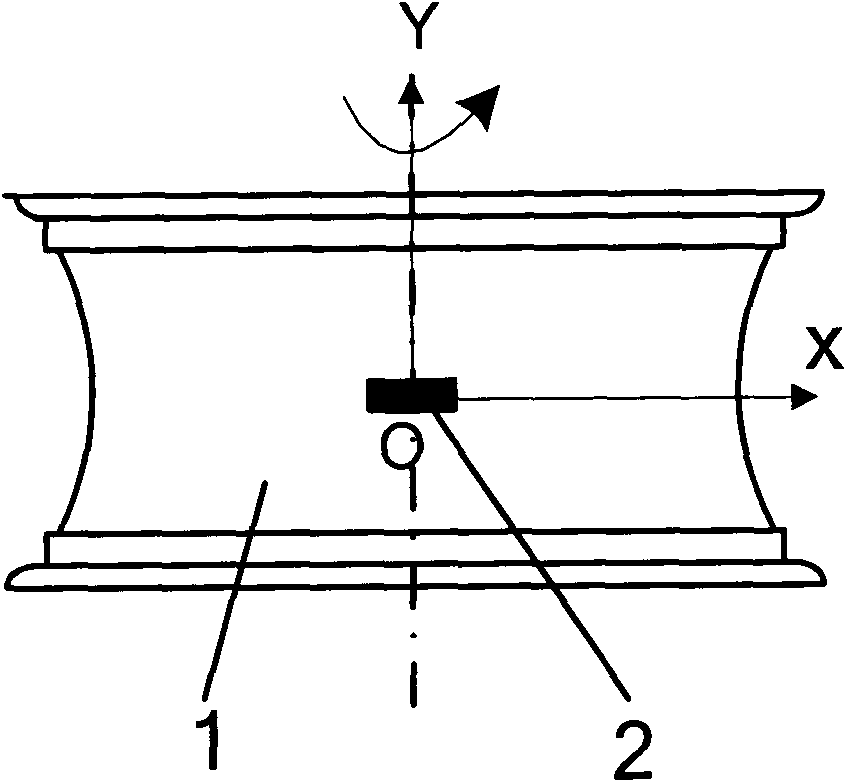

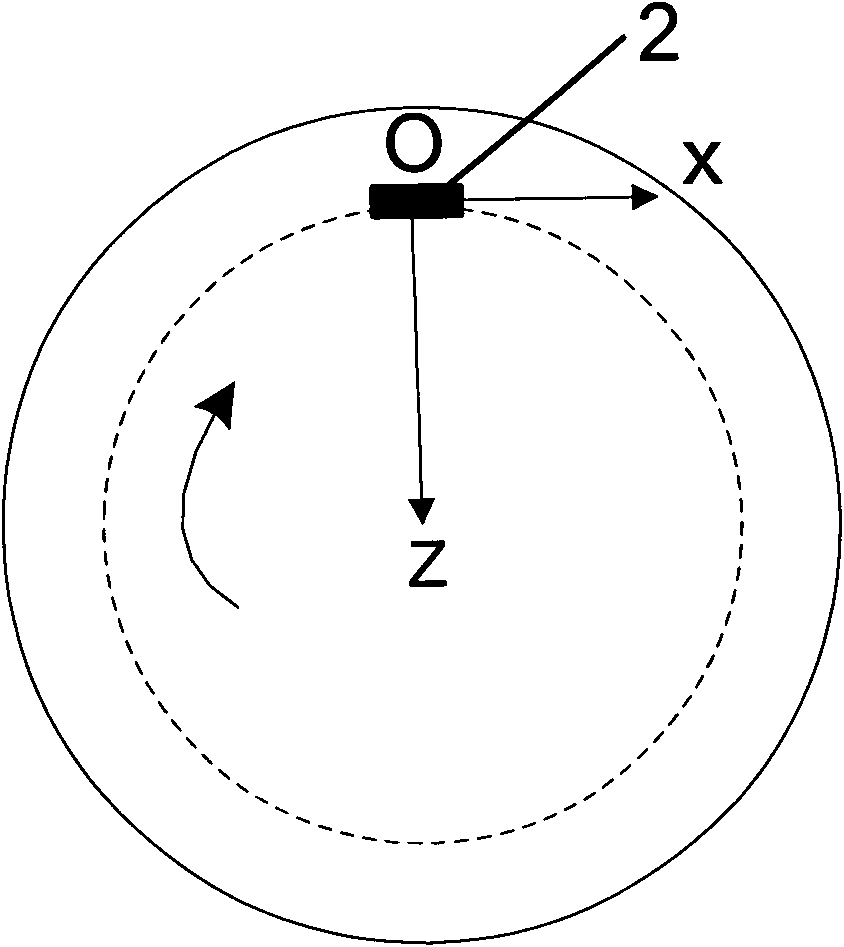

[0030] refer to figure 1 , figure 2 with image 3 The wheel-mounted intelligent sensor wheel ABS (Anti-Lock Braking System anti-lock braking system) braking performance test module is shown in the side view of the wheel, the top view of the wheel and the front view of the wheel respectively. The wheel intelligent sensor module 2 is installed in On the surface of the equatorial plane of the hub of wheel 1, the installation requirements of the module: the three sensitive axes X axis, Y axis and Z axis of the acceleration sensor point to the tangential direction of the hub, the lateral direction of the hub, and the direction of the axis of the hub; the left side is Oxyz is an orthogonal right-handed coordinate system.

[0031] Figure 4a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com