Organic polymer-silica nanocomposite material and its preparation method

A nano-composite material and organic polymer technology, applied in the field of materials, can solve the problems of many reaction steps, cumbersome operations, complicated processes, etc., and achieve the effect of good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1, the preparation of the silica composite material with hydrophilic polyethylene glycol (PEG) on the surface

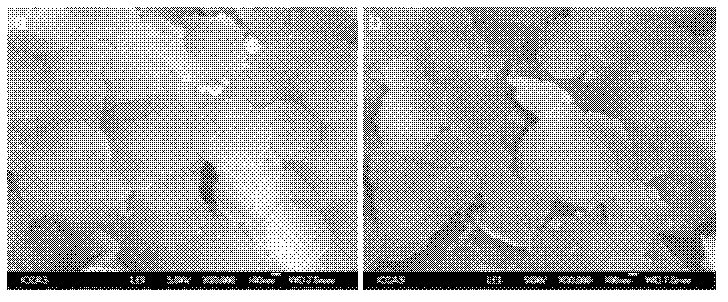

[0054] 10mL concentration is 10mg / mL block copolymer shown in formula I polyethylene glycol-polylysine (PEG 45 -b-PLL 100 ) (wherein, R is -H, m is 45, n is 100) and 2 mL of sodium phosphate buffer solution with a concentration of 0.1 M and a pH value of 7.5 are mixed, and 12 mL of the mixture is taken, and 5 mL of the obtained solution is added to it Silicic acid oligomer (the silicic acid oligomer is obtained by mixing 1.5mL of TMOS and 8.5mL of dilute hydrochloric acid with a concentration of 1mM for 5 minutes until uniform) and mix well, and react at 25°C for 2 minutes to obtain a white The turbid liquid is freeze-dried to remove moisture to obtain the silicon dioxide composite material provided by the invention with hydrophilic polyethylene glycol (PEG) on the surface.

[0055] The composite material is composed of polylysine block copolymer ...

Embodiment 2

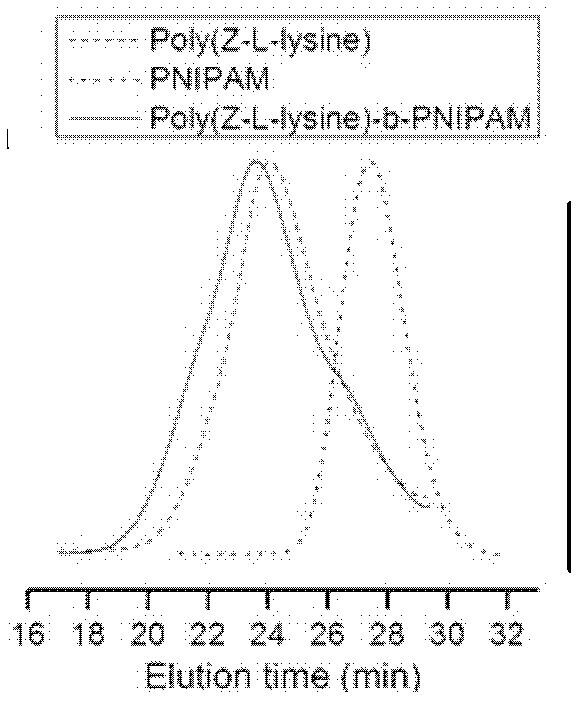

[0057] Example 2, Preparation of silica composite material with hydrophilic and temperature-responsive poly-N-isopropylacrylamide (PNIPAM) molecular chains on the surface

[0058] 10mL concentration is 10mg / mL poly-N-isopropylacrylamide-polylysine (PNIPAM) shown in formula II 35 -b-PLL 100 ) (wherein R is -NHCH(CH 3 ) 2 , m is 35, n is 100) aqueous solution and 2mL concentration is 0.1M, after the sodium phosphate buffer solution that pH value is 7.5 is mixed, take 12mL of this mixed solution, then add 5mL gained silicic acid oligomer (the The silicic acid oligomer is obtained by mixing 1.5mL of TMOS and 8.5mL of dilute hydrochloric acid with a concentration of 1mM for 5 minutes until homogeneous), and mixing well, and reacting at 25°C for 2 minutes to obtain a white turbid liquid, freeze-dried, and removed Water is removed to obtain the silicon dioxide nanosheet composite material with hydrophilic and temperature-responsive poly-N-isopropylacrylamide (PNIPAM) molecular cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com