Starch-based graft copolymer coal water slurry dispersant and preparation method thereof

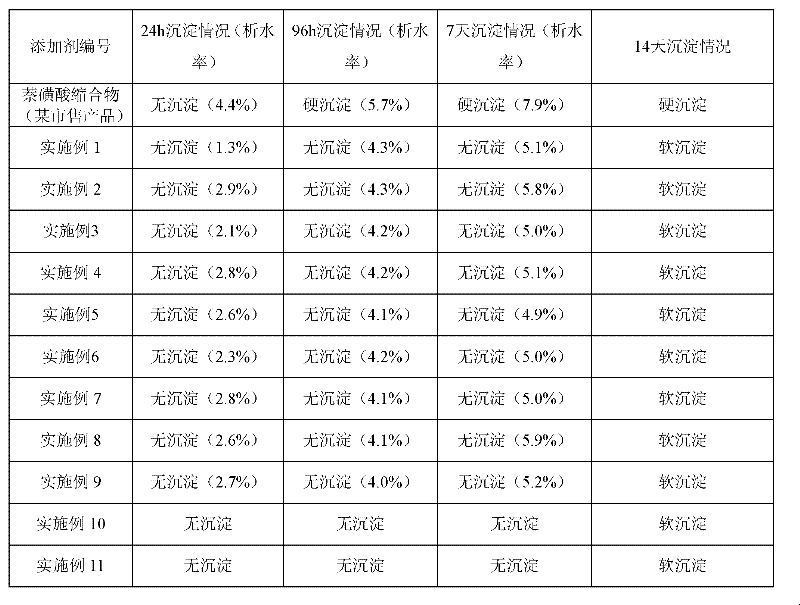

A technology of graft copolymer and coal water slurry, which is applied in the field of starch-based graft copolymer coal water slurry dispersant and its preparation, can solve the problems of high water separation rate, poor stability of coal water slurry, toxicity, etc., and achieve dispersion Good performance, improved storage stability and long stable period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Water and starch are added into the reactor to make a starch aqueous suspension with a mass fraction of 12%. The starch is saponin starch, and the starch aqueous suspension is heated to 34° C. after stirring, and then 1.8% of the starch mass is added to oxidize it. 26min, the oxidant is potassium sulfate, after the oxidation is completed, the temperature is raised and gelatinized at 84°C for 30min, and the temperature is lowered to 50°C after the heat-insulated gelatinization, and the mixed monomer and initiator are added dropwise after cooling to obtain a reaction system. Starch and mixed monomer The mass ratio of the monomer is 1: 1.2, and the addition amount of the initiator is 4% of the total mass of the starch and the mixed monomer. The reaction system is heated up and reacted at 84°C for 50min, then cooled to 26°C and used with a mass fraction of 7% The sodium hydroxide aqueous solution adjusts the pH to be 8, the mixed monomer is sodium methacrylate, and the initi...

Embodiment 2

[0019] Water and starch are added into the reactor to make a starch aqueous suspension with a mass fraction of 15%, the starch is potato starch, the starch aqueous suspension is heated up to 42°C under stirring, and then an oxidant with 3% of the starch mass is added to oxidize for 42min , the oxidizing agent is sodium persulfate. After oxidation, heat up and gelatinize at 90°C for 45 minutes, then cool down to 62°C after heat-insulating gelatinization. The mass ratio of the monomer is 1: 1.1, and the addition amount of the initiator is 3% of the total mass of the starch and the mixed monomer. The reaction system is heated up and reacted at 90°C for 95min, then cooled to 35°C and used with a mass fraction of 6%. Sodium hydroxide aqueous solution adjusts pH to be 8, and described mixed monomer is the mixture of styrene and acrylic acid, and the mass ratio of styrene and acrylic acid is 1: 5, and described initiator is sodium persulfate, potassium persulfate, ammonium persulfate ...

Embodiment 3

[0021] Water and starch are added into the reactor to make a starch aqueous suspension with a mass fraction of 20%. The starch is tapioca starch, and the starch aqueous suspension is heated up to 50°C under stirring, and then an oxidant with 5% of the starch mass is added to oxidize for 60min. , the oxidizing agent is potassium persulfate. After oxidation, heat up and gelatinize at 95°C for 60 minutes, then cool down to 70°C after heat-insulating gelatinization, and then drop the mixed monomer and initiator at the same time to obtain a reaction system. The mass ratio of the monomer is 1: 1.5, and the addition amount of the initiator is 5% of the total mass of the starch and the mixed monomer. The reaction system is heated up and reacted at 95°C for 120min, then cooled to 40°C and used with a mass fraction of 10% Sodium hydroxide aqueous solution adjusts pH to be 9, and described mixed monomer is acrylic acid, and described initiator is potassium persulfate, and described initia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com