Solid oxide fuel cell structure and preparation method thereof

A solid oxide, fuel cell technology, used in solid electrolyte fuel cells, fuel cells, battery electrodes, etc., to achieve the effect of improving cathode performance, improving the ability to adsorb oxygen and the performance of dissociating oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

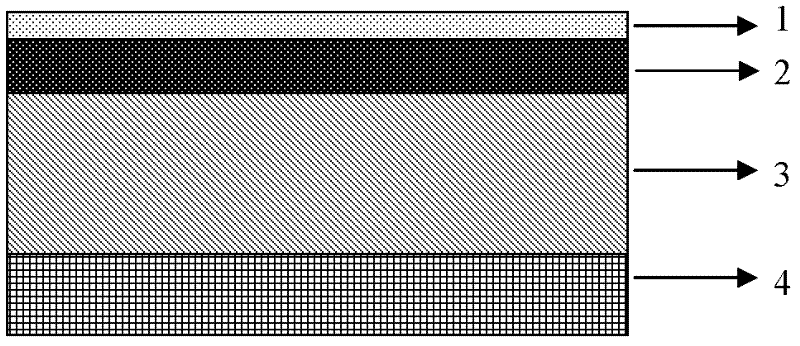

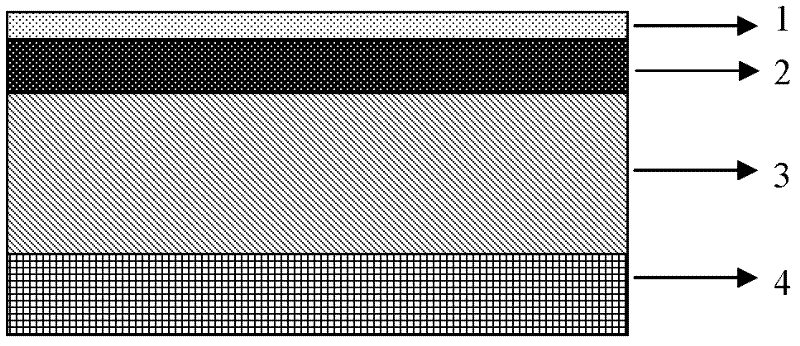

[0015] The battery structure is supported by the electrolyte layer 3, YSZ is used as the electrolyte material, and a layer of LSM (La 0.8 S 0.2 MnO 3 ) layer 2, the battery anode layer 4 made of Ni-YSZ is prepared on the other side of the electrolyte layer 3, and a thin layer of PrBaCo with a thickness of about 2 microns is prepared on the LSM layer 2 by magnetron sputtering technology 2 o 5 In layer 1, the thin film formed after magnetron sputtering is heat-treated at 800°C for 1 hour to form a solid oxide fuel cell with a new structure nuclear material system.

Embodiment 2

[0017] The battery structure is supported by the electrolyte layer 3, YSZ is used as the electrolyte material, and a layer of LSM (La 0.8 S 0.2 MnO 3 ) layer 2, on the other side of the electrolyte layer 3, the battery anode layer 4 whose material is Ni-YSZ is prepared, and a thin layer of PrBaCo with a thickness of about 3 microns is prepared by magnetron sputtering technology on the LSM layer 2 2 o 5 In layer 1, the thin film formed after magnetron sputtering is heat-treated at 700°C for 80 minutes to form a solid oxide fuel cell with a new structure nuclear material system.

Embodiment 3

[0019] The battery structure is supported by the electrolyte layer 3, YSZ is used as the electrolyte material, and a layer of LSM (La 0.8 S 0.2 MnO 3 ) layer 2, on the other side of the electrolyte layer 3, the battery anode layer 4 whose material is Ni-YSZ is prepared, and a thin layer of PrBaCo with a thickness of about 4 microns is prepared by magnetron sputtering technology on the LSM layer 2 2 o 5 In layer 1, the thin film formed after magnetron sputtering is heat-treated at 900°C for 50 minutes to form a solid oxide fuel cell with a new structure nuclear material system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com