Filter for sea water desalination pretreatment

A pretreatment and filter technology, which is used in seawater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. The filter beam is not level and other problems, to achieve the effect of strong pollution capacity, low investment in infrastructure, and long recoil cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

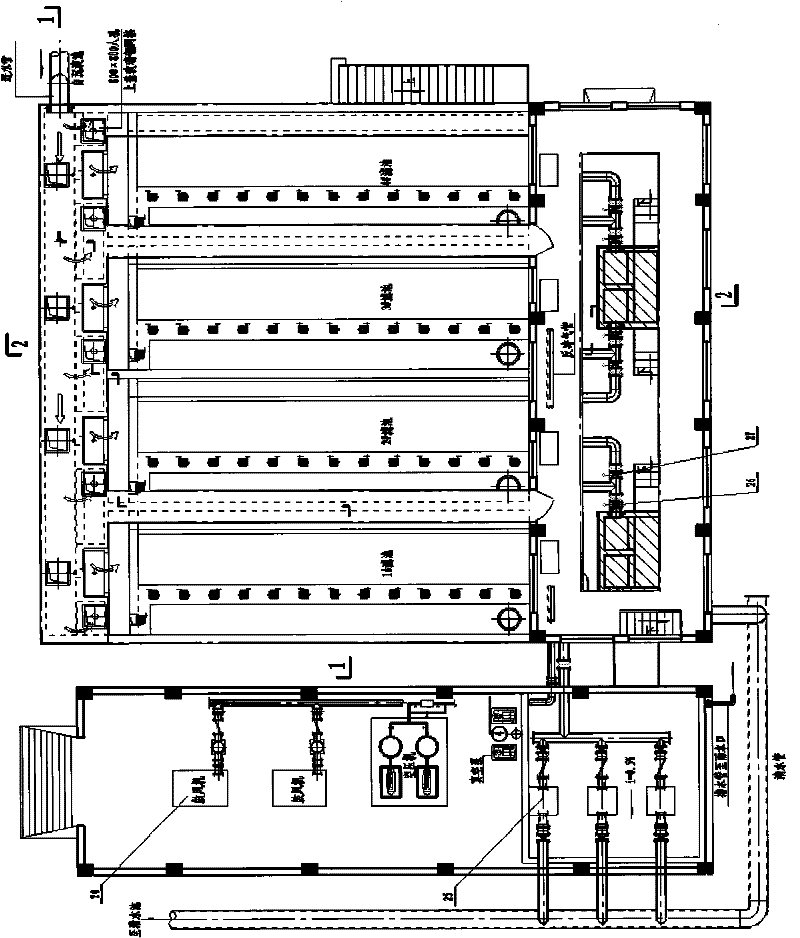

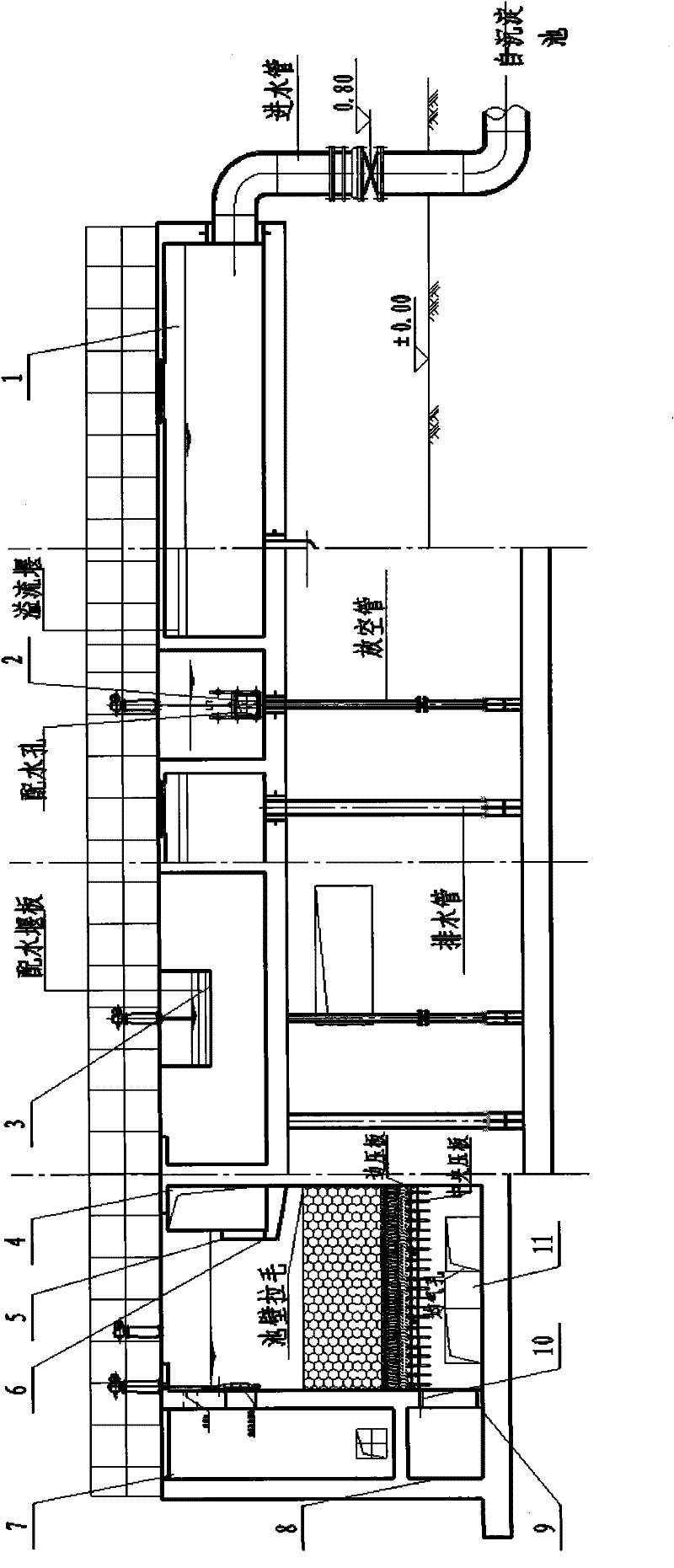

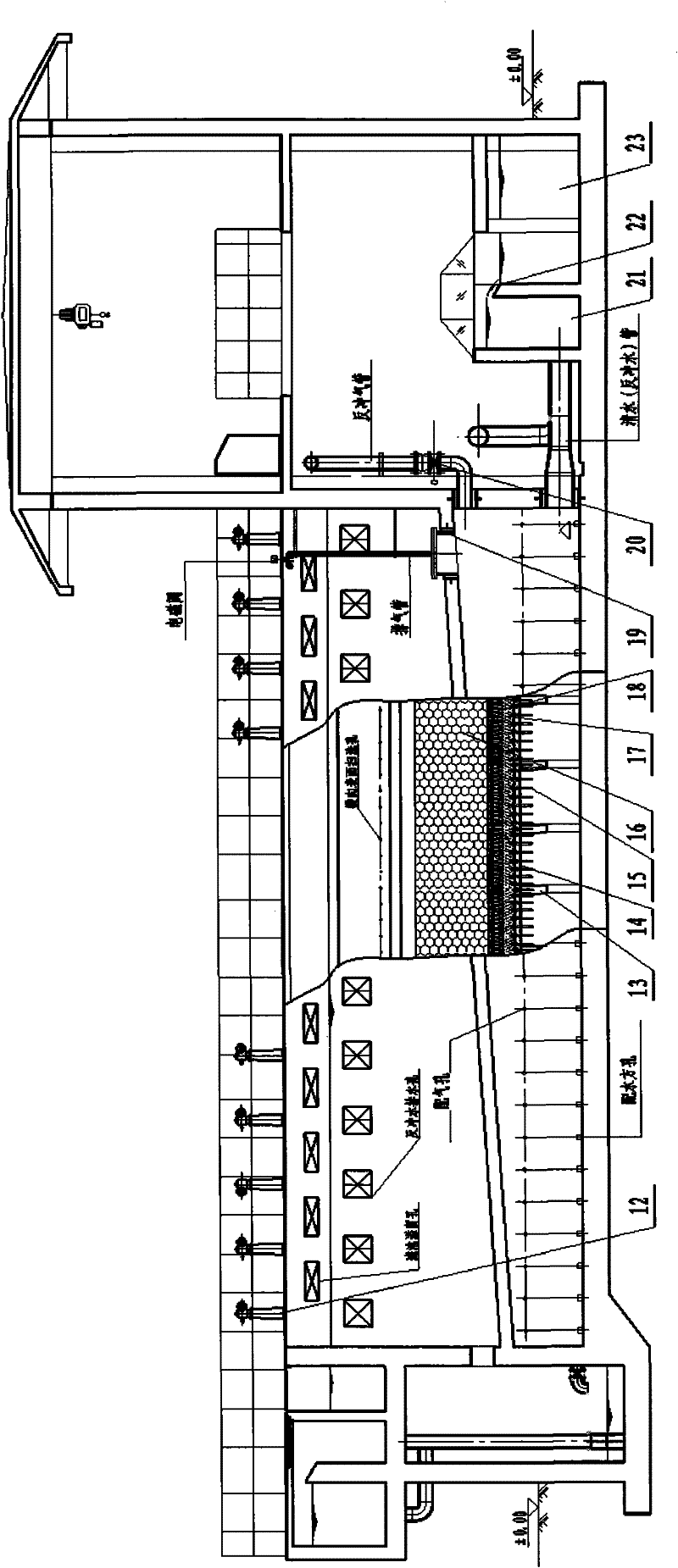

[0032] As shown in the figure: a filter tank for seawater desalination pretreatment, the main body of the filter tank adopts a reinforced concrete structure. Since the inside and outside of the filter tank are in the seawater corrosive medium environment, it is corrosive to concrete and internal steel bars. In order to improve the durability of the filter, add seawater corrosion-resistant RMA preservative to the concrete; the inner surface of the concrete in contact with seawater is painted with seawater-resistant anticorrosion paint; the steel bars in the concrete are painted with steel bar rust remover; All metal materials are made of high-alloy duplex stainless steel S32205 (ASTM), and non-metal materials are made of seawater corrosion-resistant materials such as FRP glass fiber reinforced plastics, ABS engineering plastics and EPDM rubber.

[0033] According to the flow characteristics of the fluid, in order to ensure the uniform distribution of air and water on the filter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com