Preparation method for directly drained blow molded transfusion soft bag

A technology of infusion soft bags and straight row type, which is applied in the field of medical supplies, and can solve problems such as bag blanks not being filled, products that cannot be formed, and infusion soft bags with a low pass rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

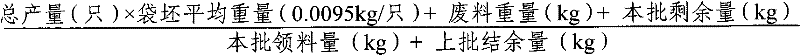

Image

Examples

Embodiment 1

[0021] The specification of inline blow molding infusion soft bag is: 100ml

[0022] Medical polypropylene particles are used as raw materials during the preparation of the straight row type blow-molded infusion soft bag. The preparation method is to prepare the bag blank by injection molding in an injection molding machine (the model of the injection molding machine is CJ380M3V) and put the bag blank into the blow molding machine (blowing machine). The plastic machine model is SUPRA-800MB10) and carry out two steps of bag blowing, each process parameter during preparation is as follows:

[0023] ① When preparing the bag blank by injection molding, the temperature of the main channel is controlled by the temperature controller to set the temperature at 210 ° C, and the temperature of the sub-runner is 320 ° C.

[0024] ②Relevant parameters of the injection molding machine are shown in Table 1

[0025] Table 1

[0026] Starting position(mm)

Pressure (Kpa)

s...

Embodiment 2

[0042] The difference from Example 1 is that the cylinder temperature is 180°C when the bag blank is injection molded, the blowing pressure is 1.6Mpa, the cooling water pressure is 0.2Mpa, and the cooling water temperature is 45°C.

[0043] According to statistics, the qualification rate of the inline infusion soft bag prepared by the method in this embodiment is 96%.

Embodiment 3

[0045] The difference from Example 1 is that the barrel temperature is 200°C when the bag blank is injection molded, the barrel temperature is 180°C when the bag blank is injection molded, the blowing pressure is 2.2Mpa when the bag is blown, the cooling water pressure is 0.5Mpa, and the cooling water pressure is 0.5Mpa. The water temperature is 50°C.

[0046] According to statistics, the pass rate of the inline infusion soft bag prepared by the method in this example is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com