Heat-removal LED (light-emitting diode) integrating SiC substrate and diamond film

A diamond film and diamond technology, applied in the field of LED particle manufacturing and packaging, can solve problems such as affecting the life of LEDs, poor thermal conductivity and heat dissipation performance of silicon wafers, and achieve the effects of improving heat dissipation, reducing heat generation, and improving lifespan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

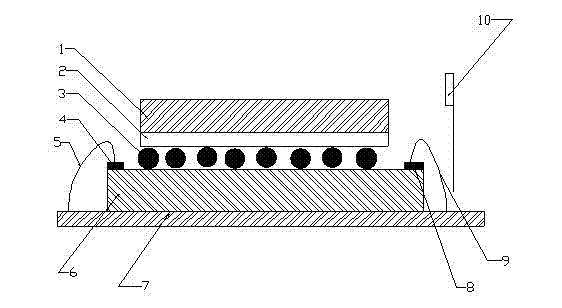

[0016] Such as figure 1 shown.

[0017] An LED that integrates a SiC substrate and a diamond film for heat dissipation, it includes a PCB board 7, the heating surface of the PCB board 7 is in contact with the bottom surface of the diamond substrate 6, and the diamond substrate 6 can be conductively doped Diamond is prepared by hot wire CVD deposition method. In order to increase the heat dissipation area, a fine structure that can increase the heat dissipation area, such as a continuous concave-convex structure, can be provided on the side of the diamond substrate 6 that is in contact with the PCB board 7 . The upper bottom surface of the diamond substrate 6 is connected to the active layer 2 through the flip chip layer 3, and the active layer 2 is grown on the SiC epitaxial substrate 1; the P-type electrode 4 and the N-type electrode 8 that control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com