High-torque continuously variable transmission

A technology of continuously variable transmission and continuously variable transmission unit, which is applied to belts/chains/gears, mechanical equipment, transmission devices, etc., and can solve problems such as the inability to meet the demand for high torque, and meet the demand for high power and high torque the effect of the demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

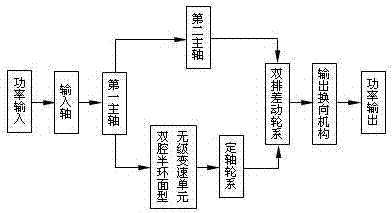

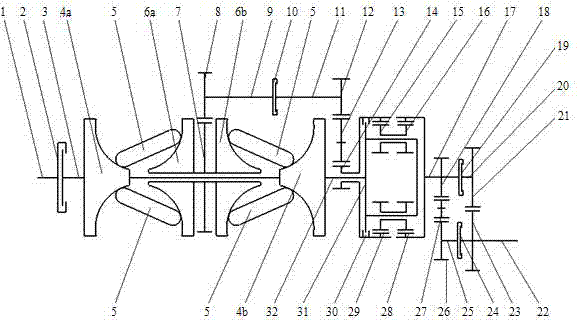

[0010] see figure 1 , 2 , High-torque continuously variable transmission, including traction-driven double-cavity semi-torusal continuously variable transmission unit, fixed-axis gear train, double-row differential gear train and output reversing mechanism. Among them, the double-cavity semi-torus type continuously variable transmission unit includes 2 input cones (4a, 4b), 2 output cones (6a, 6b) and 4 power transmission rollers (5), the input cone (4a ) and the output cone (6a) form a semi-annular cavity, in which two power transmission rollers (5) are symmetrically distributed; similarly, the input cone (4b) and the output cone (6b) A semi-annular cavity is formed, and two power transmission rollers (5) are symmetrically distributed in the cavity; the fixed-axis gear train consists of the first gear (7), the second gear (8), the first countershaft (9 ), the second clutch (10), the second countershaft (11), the third gear (12), the fourth gear (13), and the fifth gear (14)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com