Milling machine dual-purpose gearbox

A gear box, dual-purpose technology, applied in milling machine equipment, details of milling machine equipment, large fixed members, etc., can solve the problems such as the inability to quickly realize the switching between vertical and horizontal milling, the labor intensity of workers, and the loss of spindle accuracy. , to achieve the effect of shortening auxiliary processing time, low labor intensity and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

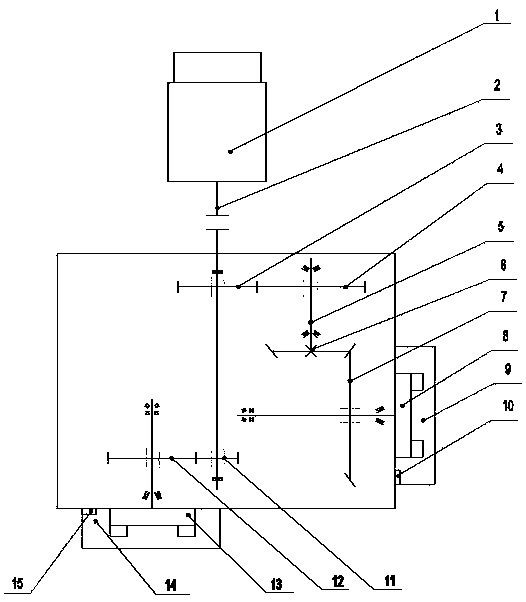

[0012] A milling machine dual-purpose gearbox, such as figure 1 As shown, it includes: a motor 1 and a gear box, the motor 1 is installed outside the gear box, the motor 1 and the gear box are connected through the input shaft 2, and the gear box is installed inside Shaft 5, horizontal driving gear 3, horizontal driven gear 4, driving arc bevel gear 6, driven arc bevel gear 7, vertical driving gear 11, vertical driven gear 12, the input shaft 2 The horizontal driving gear 3 and the vertical driving gear 11 are installed on the shaft 5, the horizontal driven gear 4 and the driving arc bevel gear 6 are installed on the shaft 5, and the horizontal driving gear 3 and the horizontal driving gear 6 are installed on the shaft 5. The driven gear 4 is meshed, the vertical driving gear 11 is meshed with the vertical driven gear 12, the driving circular arc be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com