Conical damping hole type buffer for undercarriage of passenger plane

A technology of damping holes and buffers, which is applied in the direction of shock absorbers, shock absorbers, mechanical equipment, etc., to achieve the effects of continuous and uniform load distribution, simple structure, and full shock absorbing stroke curve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

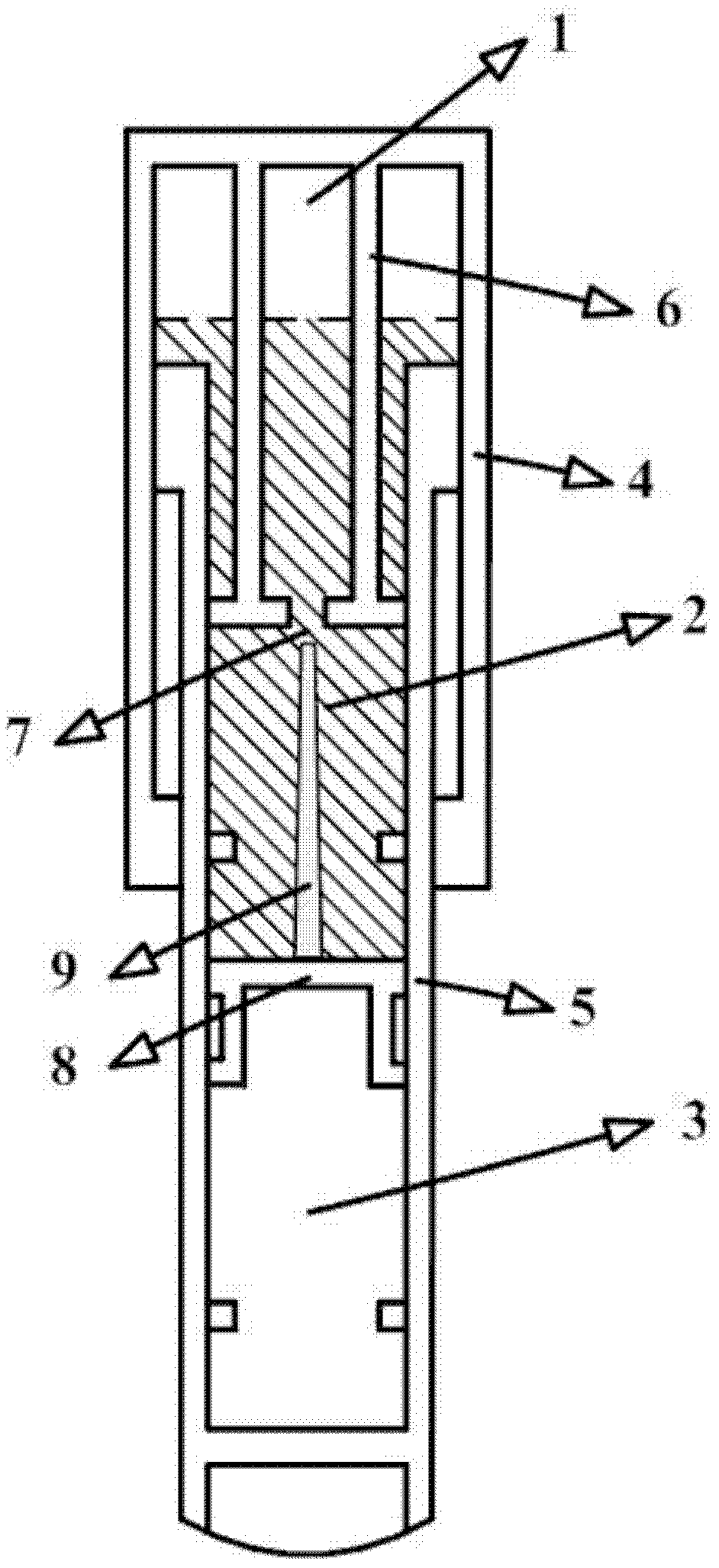

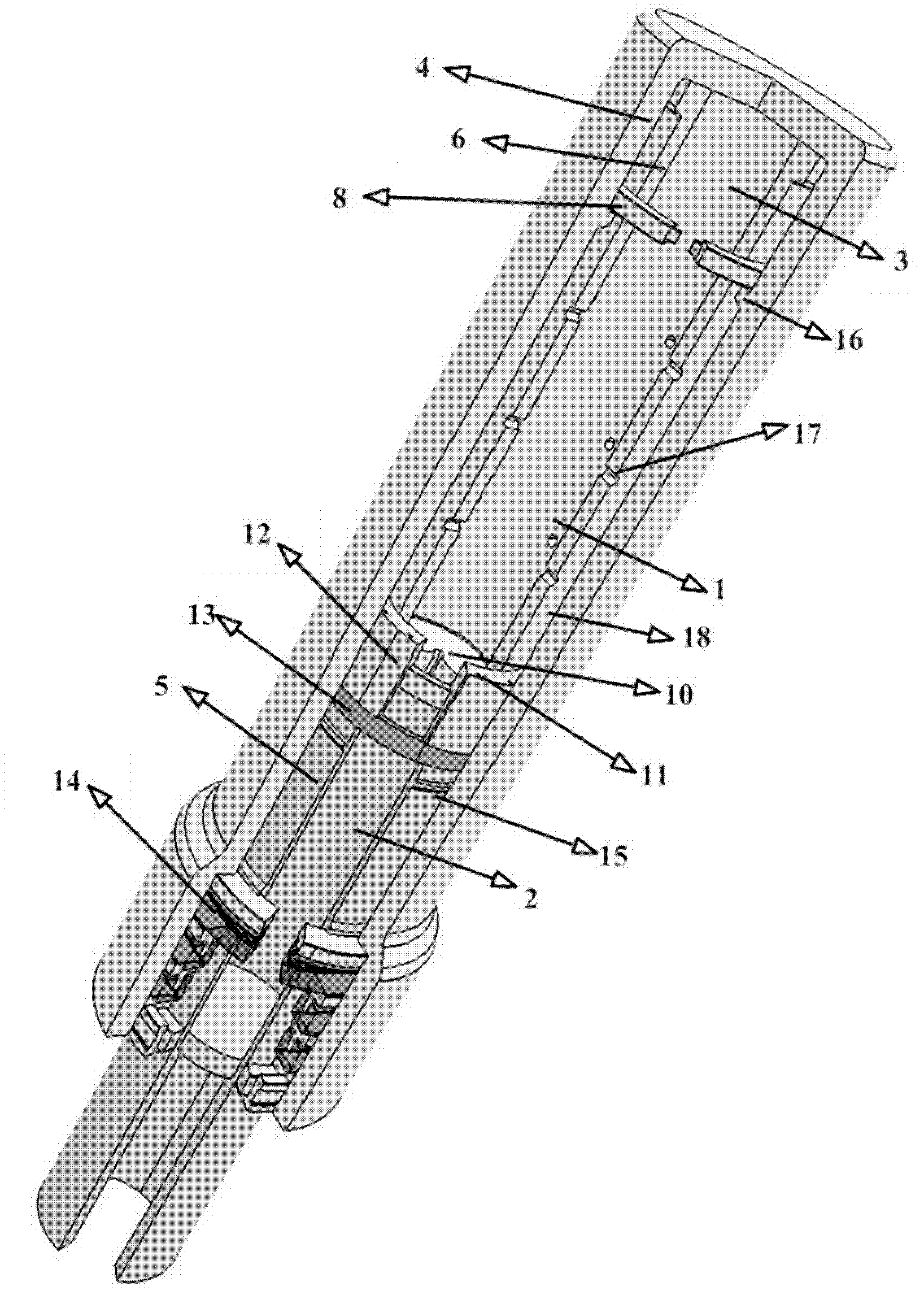

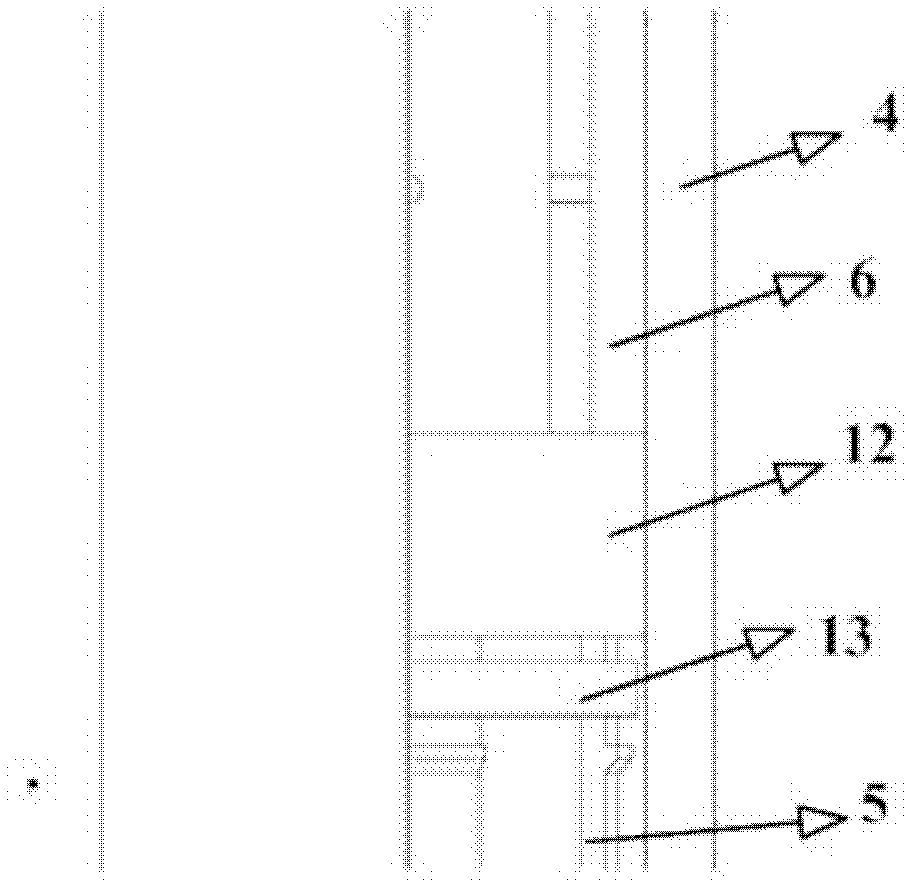

[0024] The present invention proposes a kind of conical damping hole type buffer of passenger aircraft landing gear, such as figure 2 , Figure 3-A and Figure 3-BAs shown, it includes an external fixed assembly, an internal moving assembly and a separation part; wherein the external fixed assembly includes an external actuator 4, a stroke plunger 6 and a sealing device structure 14, and the internal moving assembly includes an internal actuator 5 and a damping piston Head 12, separate components including damping brake valve 13 and air chamber diaphragm piston 8. The bottom of the inner cavity of the outer actuator 4 is provided with an inner actuator 5, and a sealing device structure 14 is arranged between the outer wall of the inner actuator 5 and the inner wall of the outer actuator 4 for sealing, and the The sealing device structure 14 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com