Scraper knife blade purposed steel with Brinell hardness of 470-520 and production method thereof

A technology of Brinell hardness and cutting edge, applied in the field of wear-resistant steel, can solve the problems of low production cost, poor cold bending performance of steel plate, different hardness levels, etc., and achieve stable production process, good welding performance and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

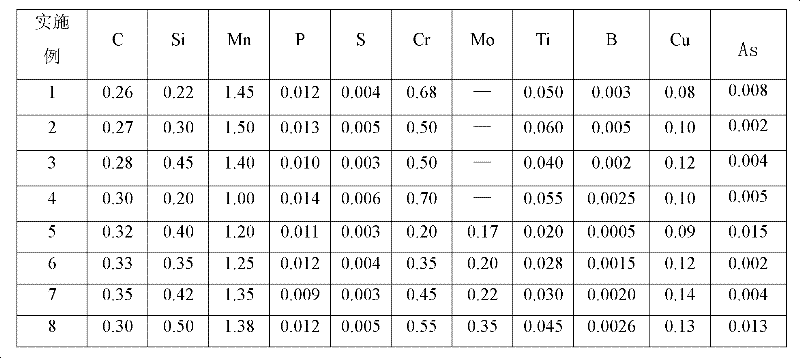

[0025] The steel composition of the embodiment of the present invention is shown in Table 1, and its production technology is carried out according to the following steps:

[0026] 1) Smelting: Desulfurization of molten iron, compound blowing at the top and bottom of the converter, RH vacuum degassing treatment and composition fine-tuning, the whole process is protected and poured into a chemical composition and weight percentage: C 0.26-0.35%, Si≤0.20-0.50%, Mn 1.0~1.50%, P≤0.020%, S≤0.015%, Cr 0.20~0.70%, Ti 0.020~0.06%, Mo: ≤0.35%, B 0.0005~0.0050%, Cu≤0.3%, As≤0.018%, The rest is continuous casting slabs of Fe and unavoidable impurities;

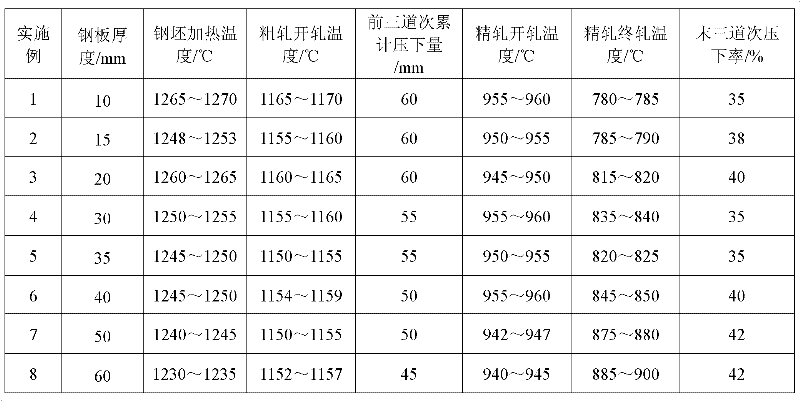

[0027] 2) Heating the continuous casting slab and fully austenitizing it at 1230-1270°C;

[0028] 3) Preliminary rolling is carried out, the rolling start temperature is controlled at 1150-1170°C, and the cumulative reduction in the first three passes is controlled at 45-60mm;

[0029] 4) Finish rolling, the starting rolling temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com