Oxygen top-blown converter flue gas purification and waste heat recovery system device

A waste heat recovery system and converter flue gas technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of ineffective use of wet dust, low waste heat recovery rate of flue gas, and high operating costs, and achieve saturated steam The effect of large volume, small resistance, and reduced fan energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

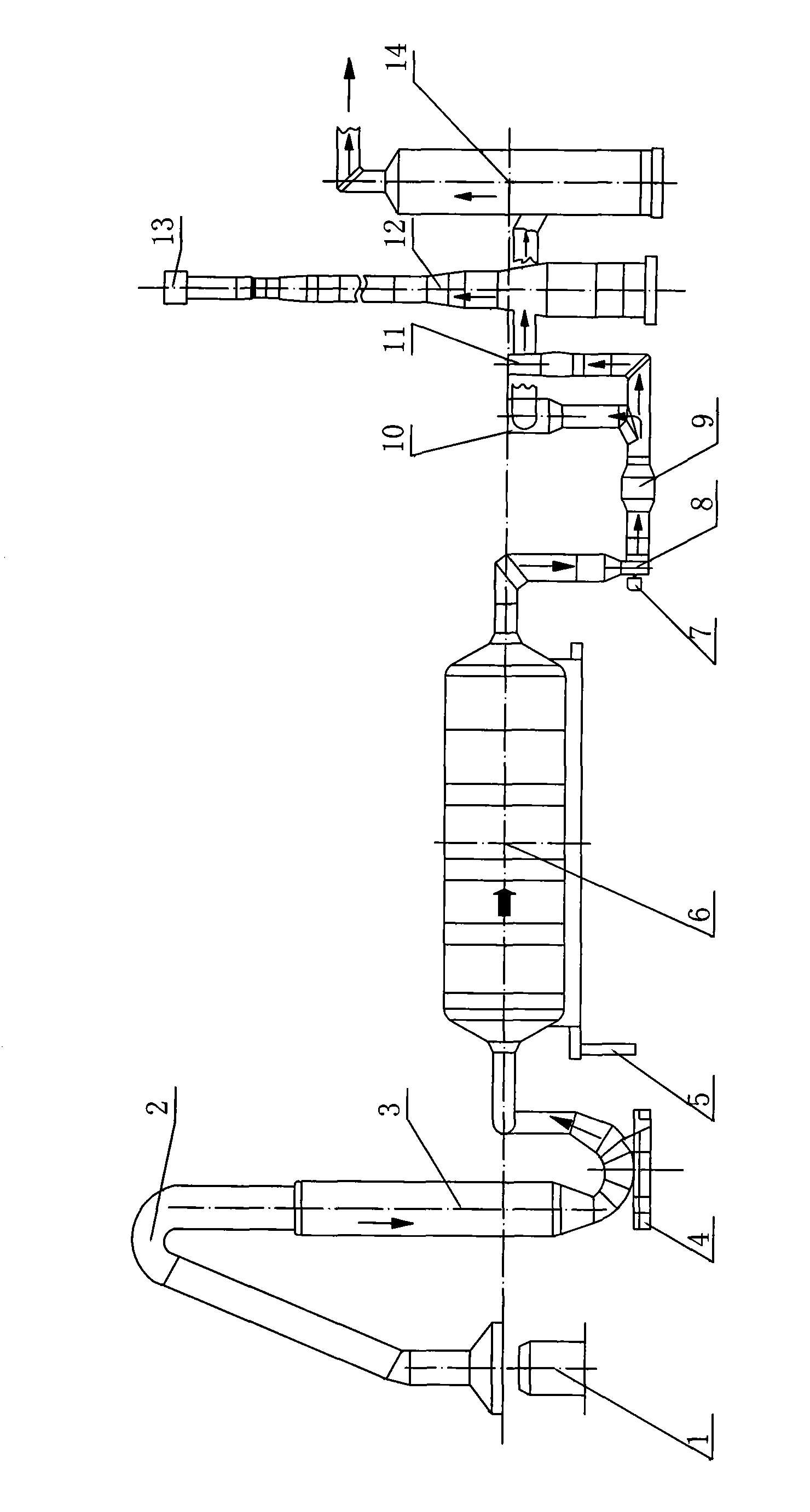

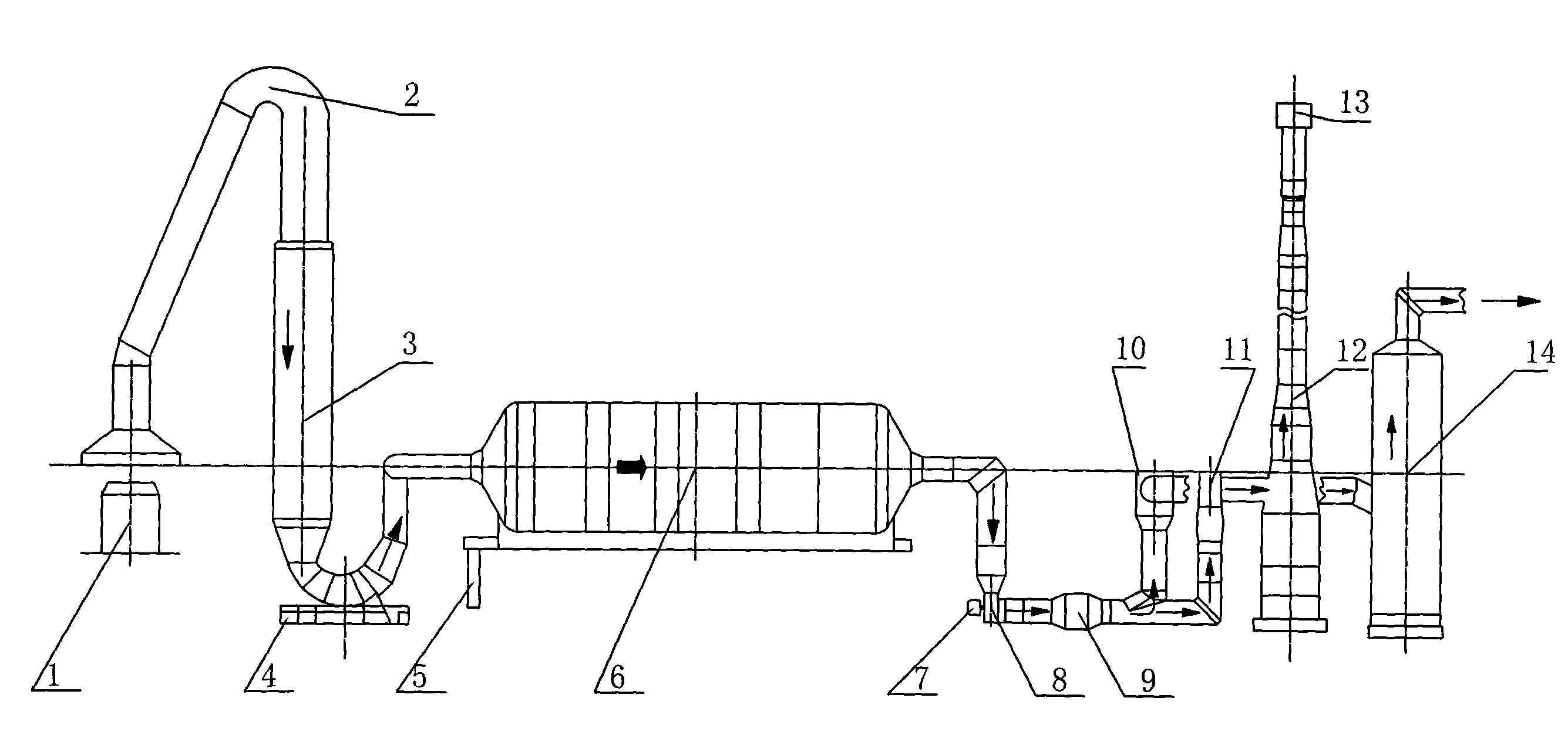

[0010] In the figure: the converter 1 is cylindrical, and the vaporization cooling flue 2 is arranged on the top of the converter 1, and the vaporization cooling flue 2 is connected with the evaporative cooling tower 3, and the evaporative cooling tower 3 is connected with the arc-shaped curved pipe, and the curved pipe The lower end is equipped with a coarse ash conveying system 4, and the evaporative cooling tower 3 is connected to the electrostatic precipitator 6 through an arc-shaped elbow. 8 are connected to the upper interface, the axial flow fan 8 is provided with a motor 7, the other end of the axial flow fan 8 is connected to the muffler 9, two vertical pipes are arranged on the muffler pipe, and the front vertical pipe is provided with a gas recovery cup valve 10 , the rear end vertical pipe is provided with a gas release cup valve 11, the gas recovery cup valve 10 pipeline is connected with the middle of the gas cooling tower 14, the gas release cup valve 11 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com