Nylon composite powder material for selective laser sintering

A composite powder and laser sintering technology, which is applied in the field of nylon composite powder materials, can solve problems that limit the application and development of SLS technology, and achieve excellent SLS molding effects, good dimensional stability, and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

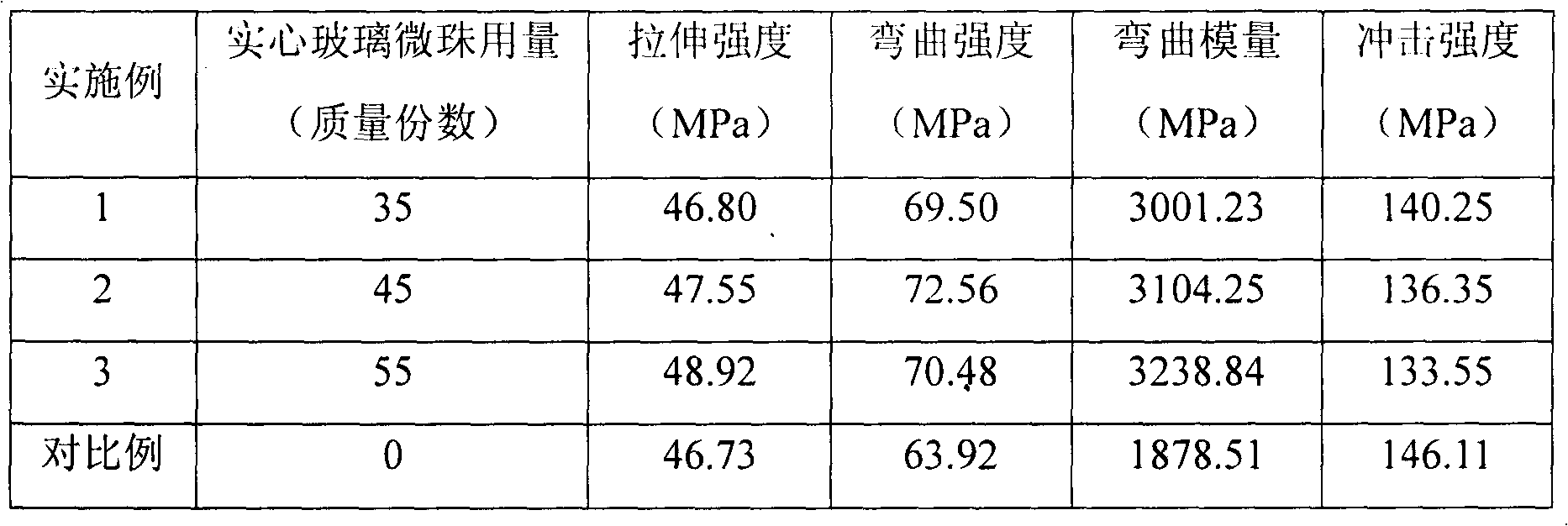

Examples

Embodiment 1

[0023] Get 300 grams of γ-aminopropyltriethoxysilane, dissolve it in 9700 grams of ethanol / water (mass ratio 95:2) mixed solvent to obtain a solution with a mass concentration of 2%; get 4000 grams of solid glass beads, add to the above solution, mixed evenly, dried at room temperature for 2 days, and then dried at 65°C for 2 hours, ball milled, and passed through a 250-mesh sieve to obtain solid glass beads with organic surface treatment;

[0024] Take 1750 grams of the above-mentioned glass microspheres and add them to the mechanical stirrer, then add 3250 grams of nylon 12 powder, 40 grams of flow aid, 40 grams of light absorber, and 40 grams of antioxidant to the stirrer, stir evenly, and pass 150 grams. Mesh sieve to obtain nylon composite powder material.

[0025] The nylon composite powder material obtained above was molded on SLS equipment, and the preparation process parameters were: laser power 12W, scanning speed 2000mm / s, sintering distance 0.1mm, sintering layer t...

Embodiment 2

[0027] Get 300 grams of γ-aminopropyltriethoxysilane, dissolve in 9700 grams of ethanol / water (mass ratio 95: 2) mixed solvent to obtain a solution with a mass concentration of 3%; get 4000 grams of solid glass beads, add to the above solution, mixed evenly, dried at room temperature for 2 days, and then dried at 65°C for 2 hours, ball milled, and passed through a 250-mesh sieve to obtain solid glass beads with organic surface treatment;

[0028] Take 2250 grams of the above-mentioned glass microspheres and add them to the mechanical stirrer, then add 2750 grams of nylon 12 powder, 45 grams of flow aid, 45 grams of light absorbing agent, and 45 grams of antioxidant to the stirrer, stir evenly, pass 150 Mesh sieve to obtain nylon composite powder material.

[0029] The nylon composite powder material obtained above was molded on SLS equipment, and the preparation process parameters were: laser power 12W, scanning speed 2000mm / s, sintering distance 0.1mm, sintering layer thickne...

Embodiment 3

[0031] Get 300 grams of γ-aminopropyltriethoxysilane, dissolve it in 9700 grams of ethanol / water (mass ratio 95:2) mixed solvent to obtain a solution with a mass concentration of 3%; get 4000 grams of solid glass microspheres, add to the above solution, mixed evenly, dried at room temperature for 2 days, and then dried at 65°C for 2 hours, ball milled, and passed through a 250-mesh sieve to obtain solid glass beads with organic surface treatment;

[0032] Take 2750 grams of the above-mentioned glass microspheres and add them to the mechanical stirrer, then add 2250 grams of nylon 12 powder, 45 grams of flow aid, 45 grams of light absorbing agent, and 45 grams of antioxidant to the stirrer, stir evenly, pass 150 Mesh sieve to obtain nylon composite powder material.

[0033] The nylon composite powder material obtained above was molded on SLS equipment, and the preparation process parameters were: laser power 12W, scanning speed 2000mm / s, sintering distance 0.1mm, sintering laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com