Loaded alpha-palladium diimine and method for preparing hyperbranched polyethylene by catalyzing with same

A diimide palladium, supported technology, applied in chemical instruments and methods, organic chemistry, production of bulk chemicals, etc., can solve the problems of low catalytic activity of α-diimide palladium catalyst, and reduce the impact and cost. , the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

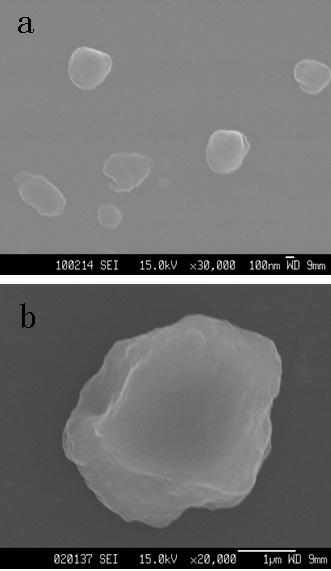

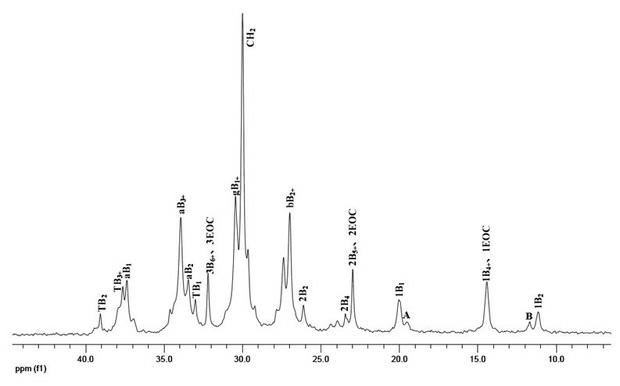

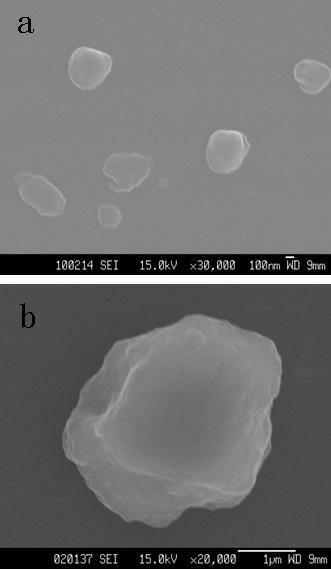

Image

Examples

Embodiment 1

[0033] Example 1: alpha -Preparation of diimine palladium complexes

[0034] Put 2.10 g (25.0 mmol) of diacetyl, 8.87 g of 2,6-diisopropylaniline (50 mmol) into a dry 150 ml round bottom flask, add 50 ml of EtOH and a small amount of acetic acid, heat to 40 ° C, and react After overnight, stop heating, cool, filter, and drain the filtrate, and then repeatedly recrystallize and drain to obtain 7.50 g of yellow crystals, which is the α-diimine ligand. The yield is 92.7%.

[0035]N 2 Under protection, put 2.10 g (5.2 mmol) of α-diimine ligand and 1.33 g (5.0 mmol) of (COD) PdMeCl into a dry Schlenk bottle with a stirring bar, add 70 ml of ether, and place under N 2 After stirring and reacting at room temperature (25 °C) for 30 hours under protection, the insoluble matter was filtered to obtain the filtrate, and the solvent was drained. The solid product was washed three times with n-hexane and dried in vacuo to obtain an orange-yellow solid, which was the α-diimine palladium...

Embodiment 2

[0037] Example 2: MgCl 2 / EtOH complex preparation steps

[0038] In a 250 ml branched round bottom flask equipped with a magnetic stirring and condensing device, add anhydrous MgCl successively at room temperature 2 10.00 g, 20.0 ml of anhydrous EtOH, then gradually increase the temperature to make MgCl 2 Dissolves to form a homogeneous clear solution. Add 50 ml of dry n-heptane to fully disperse and emulsify the solution, then drain n-heptane and excess EtOH under vacuum to obtain white powder MgCl 2 / EtOH complex, then N 2 Store under airtight protection.

[0039] All the above operations are carried out under anhydrous and oxygen-free conditions.

Embodiment 3

[0040] Embodiment 3: Acryloyl chloride treatment MgCl 2 / EtOH complex steps

[0041] Under nitrogen protection, the MgCl prepared in 2.70g embodiment 2 2 / EtOH complex was added to a 250 ml glass reaction bottle, 20 ml of n-heptane was added, stirred to form a slurry, at 0°C, 2.0 ml of acryloyl chloride was slowly added, slowly raised to room temperature, reacted for 24 h, and then the liquid was filtered out, The solid was washed three times with n-heptane, and the n-heptane was sucked dry until a fluid powder was obtained, acryloyl chloride modified MgCl 2 / EtOH complex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com