Irregular micro electrolysis iron carbon filling material

A micro-electrolytic iron, irregular technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem that waste water treatment takes a long time, the production process has high requirements, and the reaction The flushing operation is not easy and other problems, so as to achieve the effect of stable and long-lasting treatment effect, reduce the amount of manual operation, and improve the effect of sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

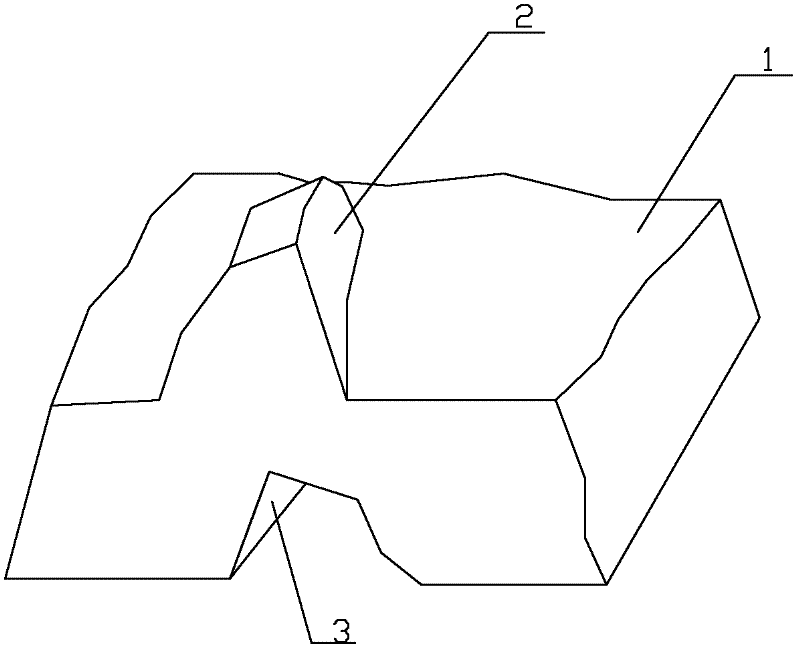

[0026] Such as figure 1 As shown, an irregular micro-electrolytic iron-carbon filler is in the shape of a block, and at least one irregular protrusion 2 and at least one irregular groove 3 are respectively arranged on the opposite end surfaces of the filler 1 .

Embodiment 2

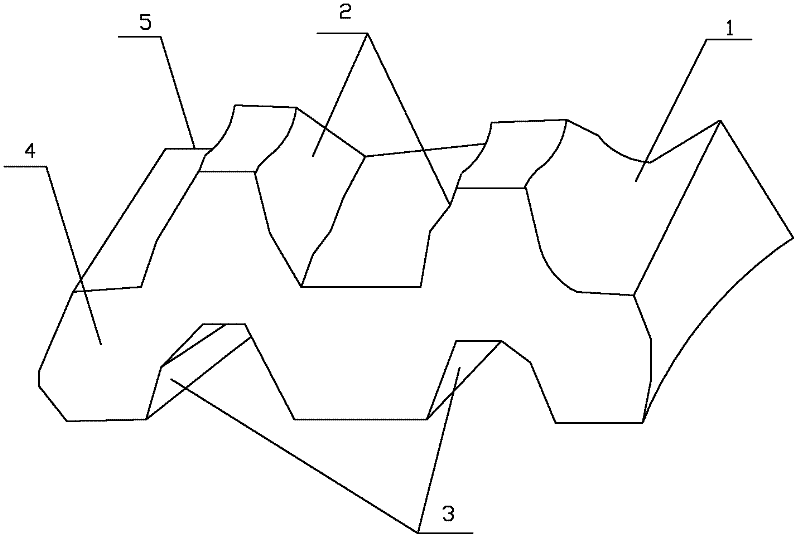

[0028] Such as figure 2 As shown, an irregular micro-electrolytic iron-carbon filler is block-shaped, and at least one irregular protrusion 2 and at least one irregular groove 3 are respectively arranged on the opposite end faces of the filler 1, and the irregular The protrusions 2 and the irregular grooves 3 are correspondingly arranged up and down on opposite end surfaces. A first side 4 is sandwiched between opposite end surfaces of the packing 1, and the opposite side of the first side 4 is a second side 5, and the irregular protrusion 2 and the irregular groove 3 are located on the first side. Between the side 4 and the second side 5 .

Embodiment 3

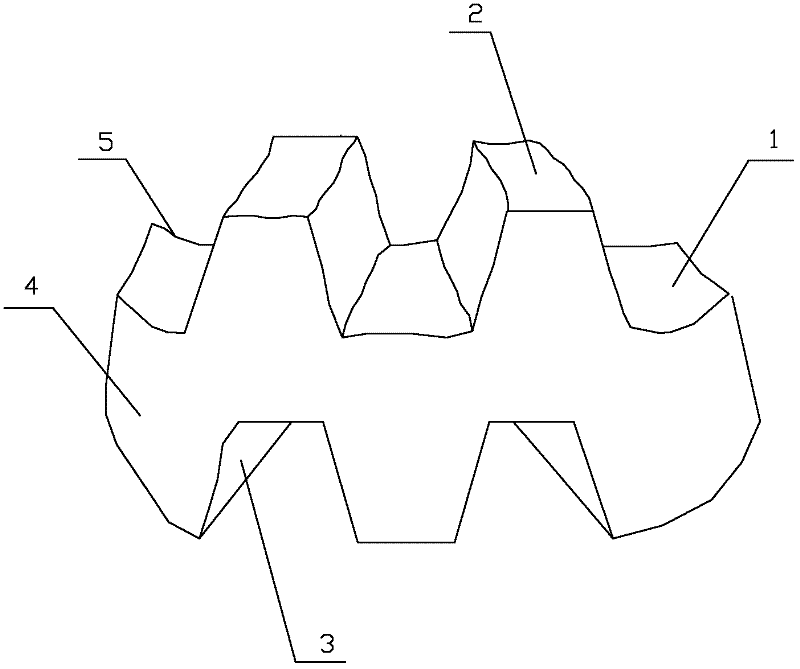

[0030] Such as image 3 As shown, an irregular micro-electrolytic iron-carbon filler is block-shaped, and at least one irregular protrusion 2 and at least one irregular groove 3 are respectively arranged on the opposite end faces of the filler 1, and the irregular The protrusions 2 and the irregular grooves 3 are correspondingly arranged up and down on the opposite end surfaces, the first side 4 is sandwiched between the opposite end surfaces of the filler 1, and the opposite surface of the first side 4 is the second side 5, The irregular protrusion 2 and the irregular groove 3 are located between the first side 4 and the second side 5, the irregular protrusion 2 and the irregular groove 3 are roughly gear-shaped, the The filler 1 is inclined as a whole and has radians.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com