Uniform molecularly imprinted polymer microspheres for use as zeranol selective adsorbent, preparation method and application thereof

A technology of zearalanol and molecular imprinting, applied in alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of cumbersome operation, poor reproducibility, and large waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

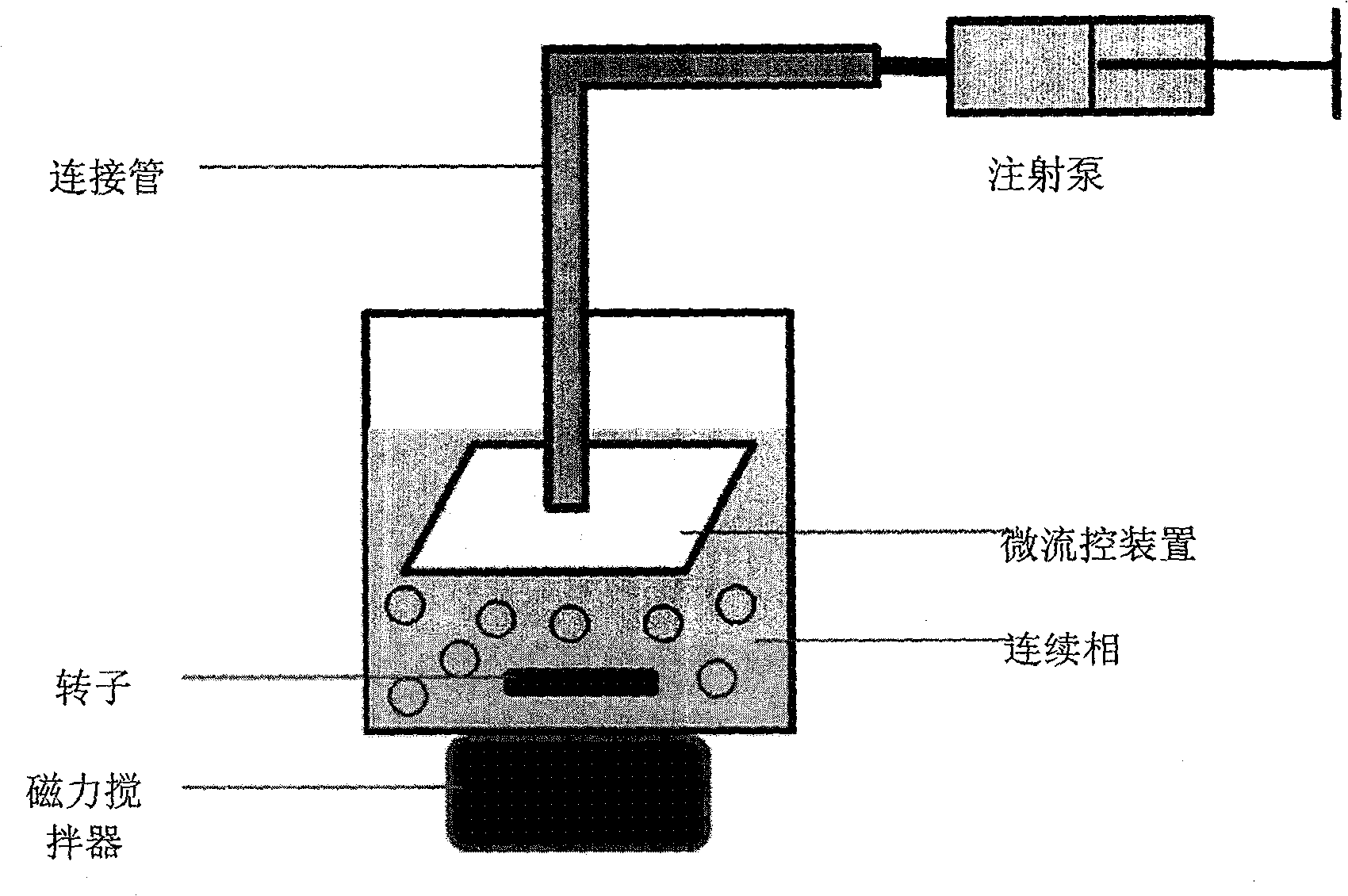

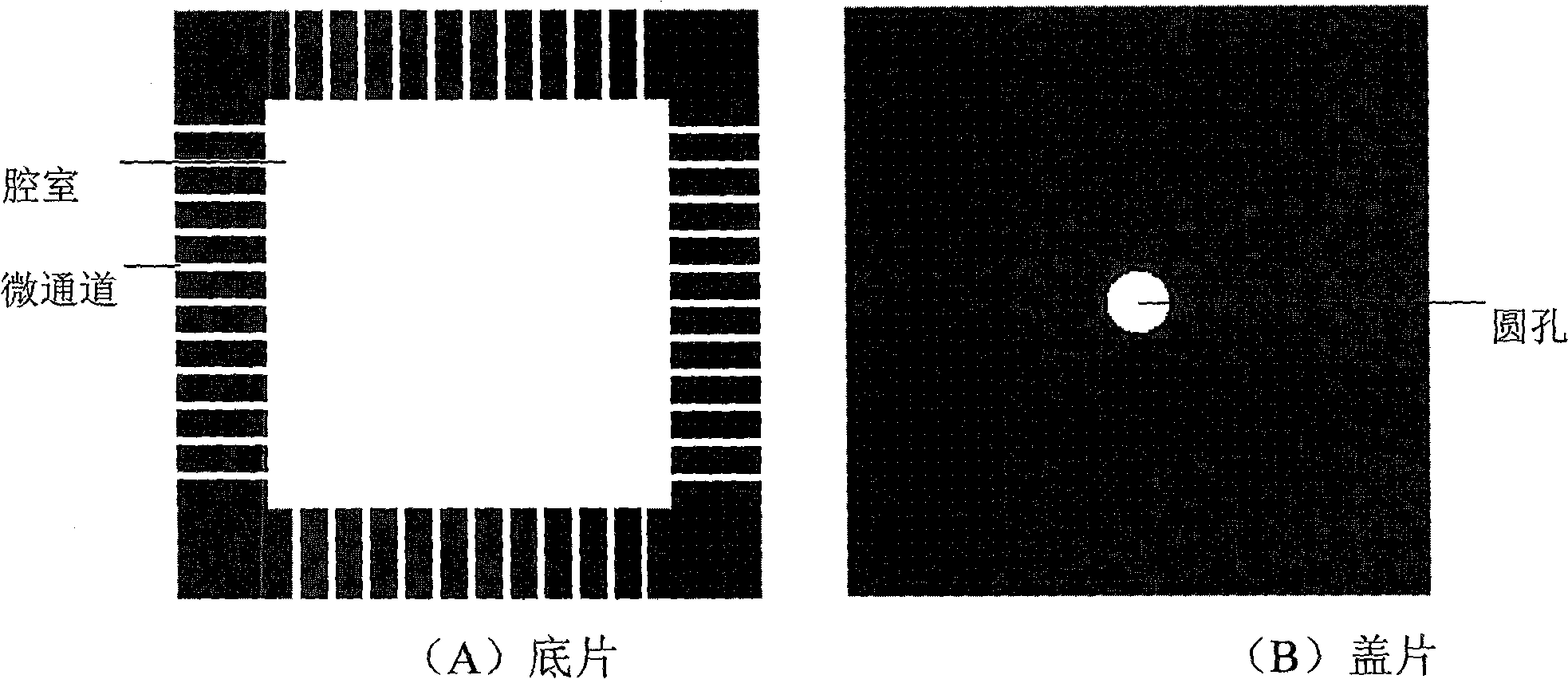

[0040] First prepare the dispersed phase solution, ultrasonically dissolve 1 mmol of the template molecule CDHB in 5 mL of the porogen chloroform and ethyl acetate (1:1 by weight), add 4 mmol of the functional monomer 4-vinylpyridine, 19 mmol of the cross-linking agent EDMA, Initiator azobisisobutyronitrile AIBN 0.20g, the solution was ultrasonically degassed for 5min, deoxygenated by nitrogen for 10min, and then the solution was moved into the syringe of the syringe pump (try to avoid air entering the syringe); the continuous phase solution was prepared, and the dispersed PVA 0.72g was added into 60mL water, stirred and dissolved, degassed by ultrasonic for 5min, deaerated by nitrogen gas for 20min, and placed in the continuous phase container.

[0041] The continuous phase was stirred at 210 rpm and sparged with nitrogen. Driven by the syringe pump, the dispersed phase solution enters the square chamber of the microfluidic device through the connecting tube, and then enters ...

Embodiment 2

[0046] First prepare the dispersed phase solution, ultrasonically dissolve 1 mmol of the template molecule CDHB in 6 mL of the porogen chloroform and ethyl acetate (4:6 by weight), add 3 mmol of the functional monomer allylpiperazine, 18 mmol of the cross-linking agent EDMA, Initiator azobisisobutyronitrile AIBN 0.22g, the solution was ultrasonically degassed for 5min, deoxygenated by nitrogen gas for 10min, and then the solution was moved into the syringe of the syringe pump (try to avoid air entering the syringe); the continuous phase solution was prepared, and the dispersed Add 0.78g of agent PVA into 66mL of water, stir to dissolve, ultrasonically degas for 5min, pass nitrogen gas for deoxygenation for 20min, and place in a continuous phase container.

[0047] The continuous phase was stirred at 230 rpm and sparged with nitrogen. Driven by the syringe pump, the dispersed phase solution enters the square chamber of the microfluidic device through the connecting tube, and th...

Embodiment 3

[0052] First prepare the dispersed phase solution, ultrasonically dissolve 1 mmol of the template molecule CDHB in 9 mL of the porogen chloroform and ethyl acetate (4:6 by weight), add 5 mmol of the functional monomer allylpiperazine, 30 mmol of the cross-linking agent EDMA, Initiator azobisisobutyronitrile AIBN 0.22g, the solution was ultrasonically degassed for 5min, deoxygenated by nitrogen gas for 10min, and then the solution was moved into the syringe of the syringe pump (try to avoid air entering the syringe); the continuous phase solution was prepared, and the dispersed Add 1.28g of agent PVA into 90mL of water, stir to dissolve, ultrasonically degas for 5min, pass nitrogen gas for deoxygenation for 20min, and place in a continuous phase container.

[0053] The continuous phase was stirred at 180 rpm and sparged with nitrogen. Driven by the syringe pump, the dispersed phase solution enters the square chamber of the microfluidic device through the connecting tube, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com