Wear resistant material for manufacturing sub-soiling shovel

A technology of wear-resistant materials and subsoiling shovels, which is applied in the field of new materials for casting subsoiling shovels, can solve the problems of dependence on imports, difficulties in small-batch manufacturing, and high prices, and achieve low manufacturing costs, low raw material prices, and good casting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

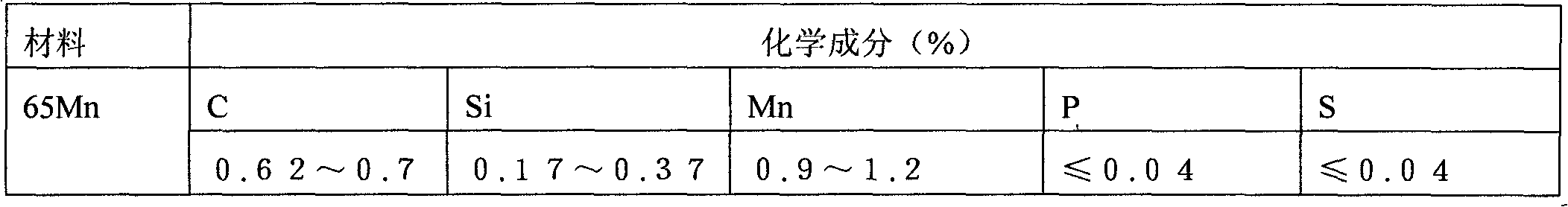

[0010] 1. The composition and ratio of casting charge: pig iron 100%, manganese steel 19-22% (66%), ferrosilicon 2.7-3.4% (75%), rare earth magnesium alloy 0.42-0.50 (No. 6).

[0011] 2. Casting ingredients and front furnace control:

[0012] Pig iron composition: C 4.3%, Mn0.57%, Si1.28%, S0.03%, P0.05%

[0013] Manganese steel composition: containing Mn63.5%

[0014] Rare earth magnesium alloy composition: Mg9.11%, Ca2.20%, Si40.20%, Re9.20%

[0015] 3. Furnace front control:

[0016] Hot metal out of the furnace temperature: 1370 ~ 1400 degrees

[0017] Nodulizer: Magnesium iron 1.0~1.8%, plus 3% ferrosilicon

[0018] When processing, add a nodulizer with a particle size of 5 mm to the bottom of the molten iron ladle, cover the top with inoculated ferrosilicon and plant ash, and then pour it into the molten iron at one time. After the nodularization reaction is stable, skim off the dregs and pour the test rod.

[0019] Casting process:

[0020] Wet mold casting, out o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com