Extrusion mechanism of rubber mould preforming machine

A preformer and model technology, applied in the field of extrusion mechanism of rubber model preformer, can solve the problems of single function, low degree of automation, low quality of rubber blank, etc., and achieves good sealing effect, stable and reliable operation, and novel structure and setting. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

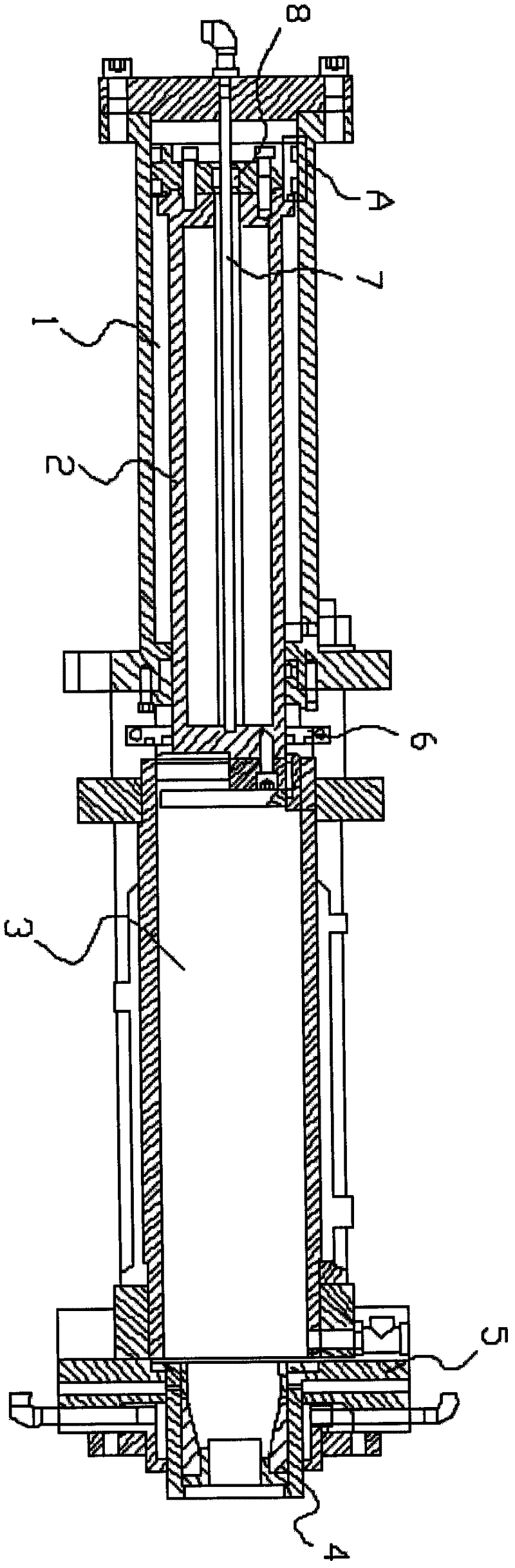

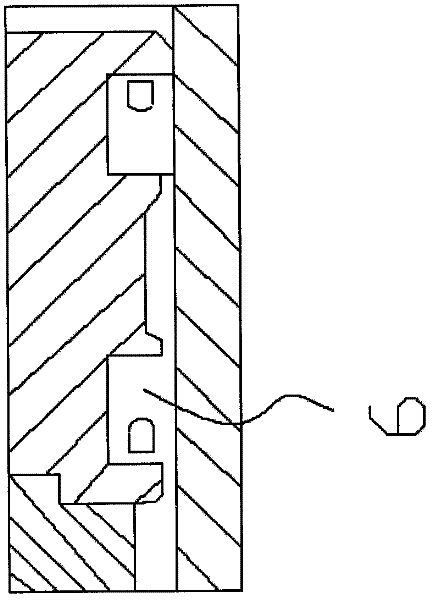

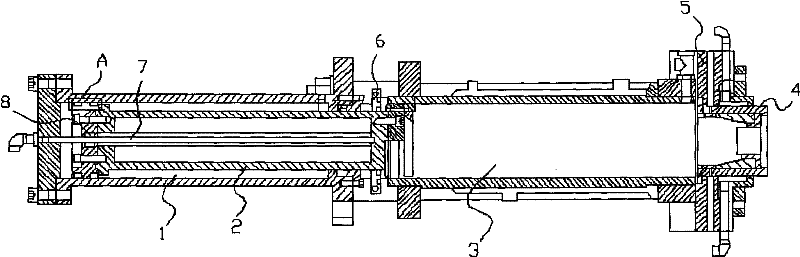

[0012] Such as figure 1 , figure 2 As shown, the extrusion mechanism of the rubber model preforming machine includes a hydraulic cylinder 1, a storage cylinder 3 and a machine head 5. The hydraulic cylinder 1 is connected to one end of the storage cylinder 3 through a sealing device 6, and the storage cylinder 3 The other end is connected with the machine head 5, the hydraulic cylinder 1 is provided with a cylinder plunger 2, and the oil cylinder plunger 2 is provided with a stroke control rod 7 and a magnetic steel 8, and the mouth shape assembly 4 is installed in the machine head 5, and the stroke control rod 7 is interspersed In the cylinder plunger 2, the Yx-shaped hole seal 9 is used to seal between the cylinder plunger 2 and the hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com