A non-metallic compensator for power plant boiler flue gas transmission pipeline

A non-metallic compensator and boiler flue gas technology, which is applied to expansion compensation devices for pipelines, pipe components, exhaust gas devices, etc. Achieve the effect of novel structure setting, prolong service life and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

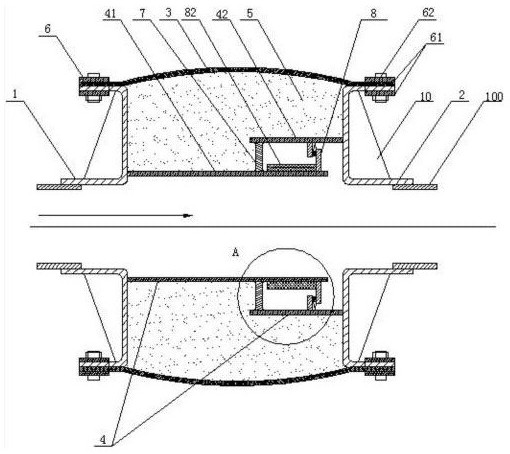

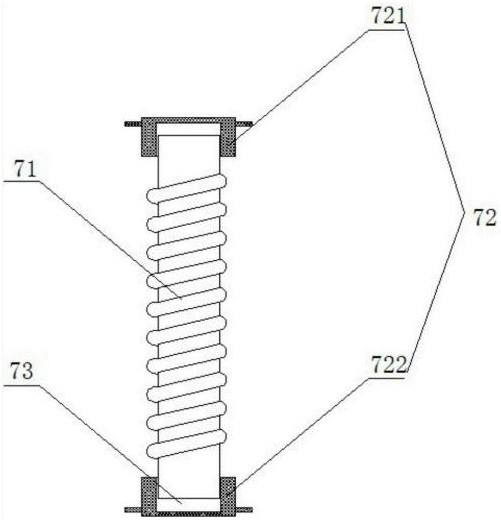

[0031] Such as figure 1 , figure 2 , Figure 4As shown, a non-metallic compensator for a power plant boiler flue gas transmission pipeline includes a left interface bracket 1, a right interface bracket 2, a skin 3, a diversion component 4, a non-metallic heat preservation component 5, and a compression component 6. Wherein, the left and right interface brackets are connected to the smoke discharge pipe 100 . The two ends of the skin are respectively connected to the left interface bracket and the left interface bracket through the pressing assembly 6. The pressing assembly includes a pressing plate 61, bolts and nuts 62; Flow tube 42, one end of the first flow guide tube is fixedly connected to the left interface bracket, and there is a gap between the other end of the first flow guide tube and the right interface bracket; one end of the second flow guide tube is fixedly connected to the right interface bracket Above, there is a gap between the other end of the second guid...

Embodiment 2

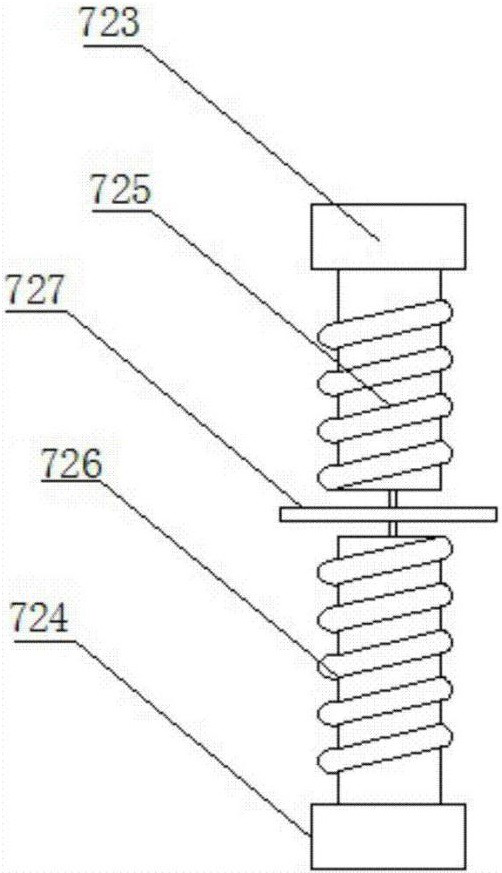

[0040] Such as image 3 As shown, in this embodiment, the elastic assembly includes an upper base 723, a lower base 724, an upper spring 725, a lower spring 726, and a middle connecting piece 727. One end of the upper base is fixedly connected to the second guide tube, and the other end is fixedly connected to The upper spring is detachably connected to the connecting piece, one end of the lower base is fixedly connected to the second guide tube, the other end is fixedly connected to the lower spring, and the lower spring is detachably connected to the middle connecting piece. The detachable connection between the spring and the middle connector is displayed by means of hooks, rings, buckles and the like in the prior art.

[0041] The rest of the structure can adopt the structure of Embodiment 1, which will not be repeated here.

Embodiment 3

[0043] Such as 5, Image 6 As shown, a non-metallic compensator for power plant boiler flue gas transmission pipeline, the non-metallic compensator for power plant boiler flue gas transmission pipeline also includes an auxiliary compensation assembly 9, the auxiliary compensation assembly includes a left vertical plate 91, a right vertical plate 92, a compensation Rod 93; the left vertical plate is vertically connected to the left interface support, and the right vertical plate is vertically connected to the right interface support; between the left vertical plate and the right vertical plate, there are left compensation rod 931, right compensation rod 932, middle compensation rod 933, left compensation rod One end of the left vertical plate is connected, and the other end of the left compensating rod is connected with the middle compensating rod by the pin shaft 94, and the middle compensating rod is connected with an end of the right compensating rod by the pin shaft, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com