Forced discharge pulverizing mill for crushed materials

A grinding machine and discharge technology, applied in grain processing, etc., can solve the problems of not being able to meet the particle size and output of various products, increase equipment use costs, and low equipment efficiency, so as to save equipment space and equipment consumables , Reduce equipment investment, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

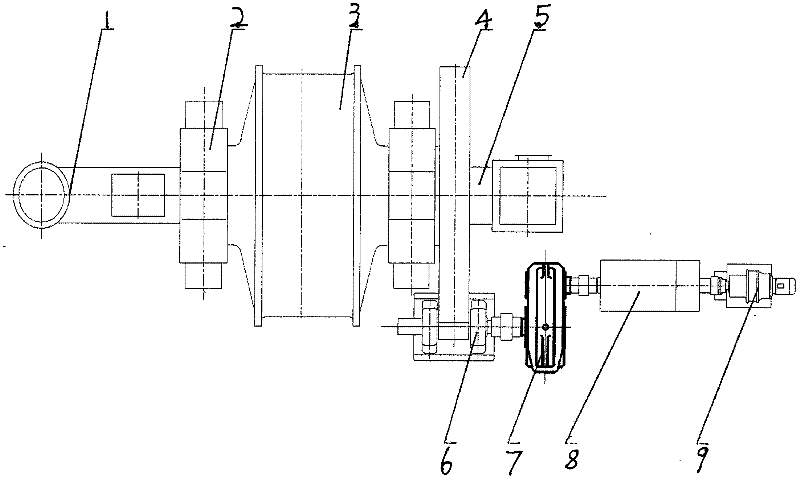

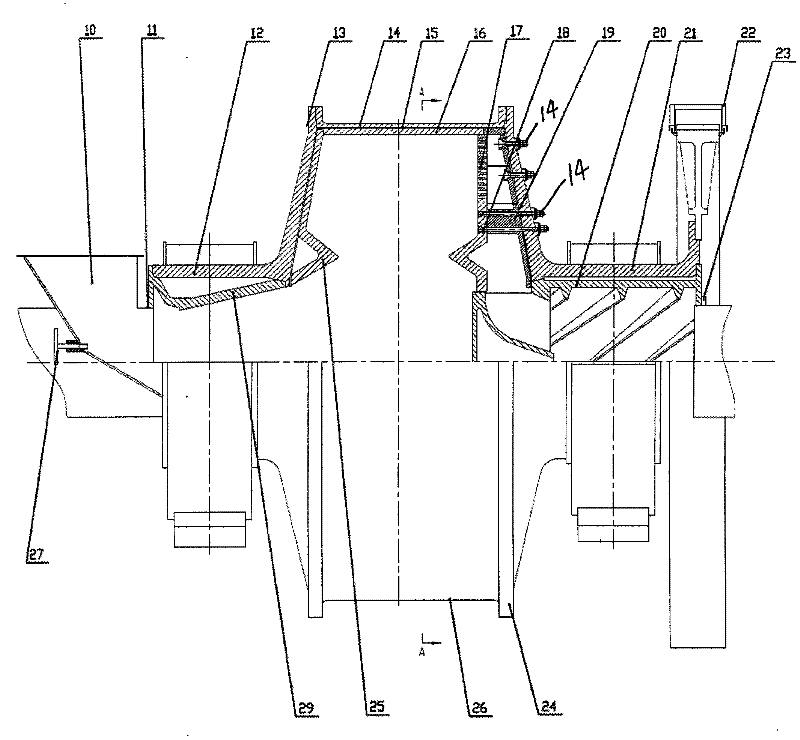

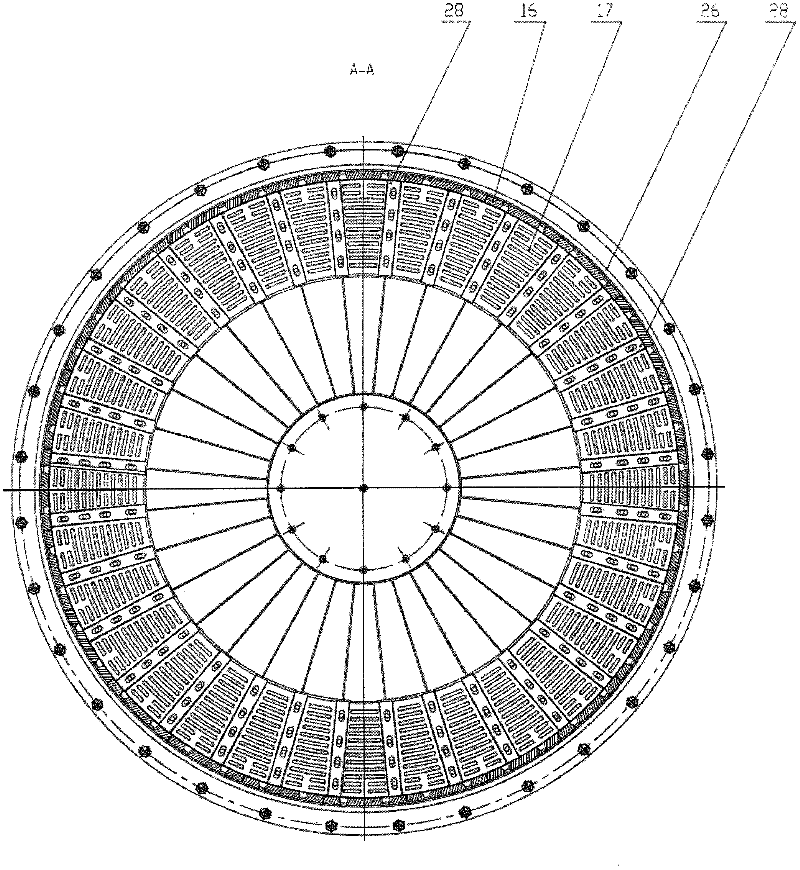

[0032] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0033] As shown in the figure, one end of the cylindrical feeding part 1 is connected to the main bearing 2, one side of the main bearing 2 is connected to the rotary part 3, the other side of the rotary part 3 is connected to the main bearing 2, and one side of the main bearing 2 is solidly connected The driven gear 4, one side of the driven gear 4 is connected to the discharge part 5; the outer end of the driven gear 4 is correspondingly meshed with the driving gear 6, one side of the driving gear 6 is connected to the speed reducer 7, and one side of the speed reducer 7 is connected to the main gear. Motor 8, one side of main motor 8 is connected with slow speed drive device 9;

[0034] One end of the feed part 1 is connected to an elbow-shaped feed port 10, and a pushing device 27 is installed at the corner of the feed port 10, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com