Printed circuit board solder resist ink coating technology and coating apparatus

A technology for printed circuit boards and coating devices, which is applied to the secondary treatment of printed circuits and the application of non-metallic protective layers. It can solve the problems of not meeting the needs of circuit boards, low efficiency, and high labor intensity. Screen printing materials, reduce production costs, reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

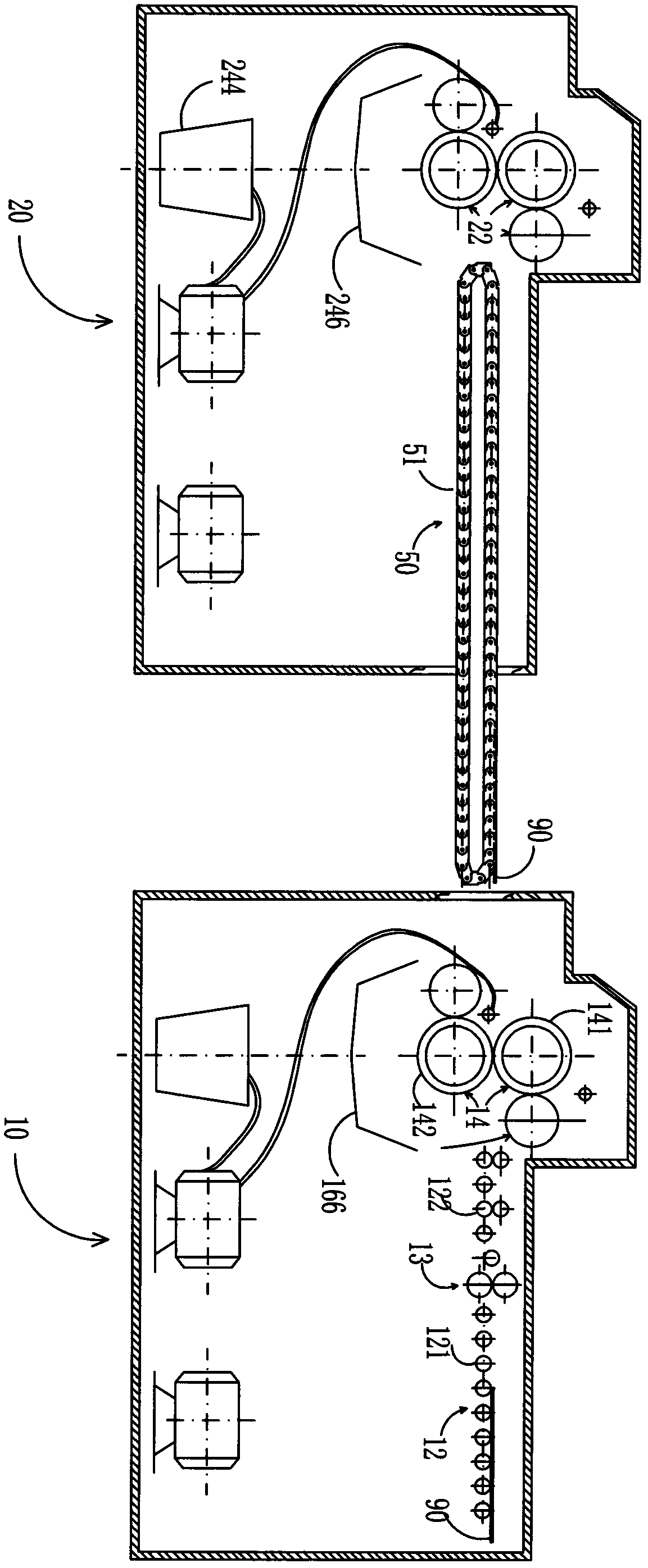

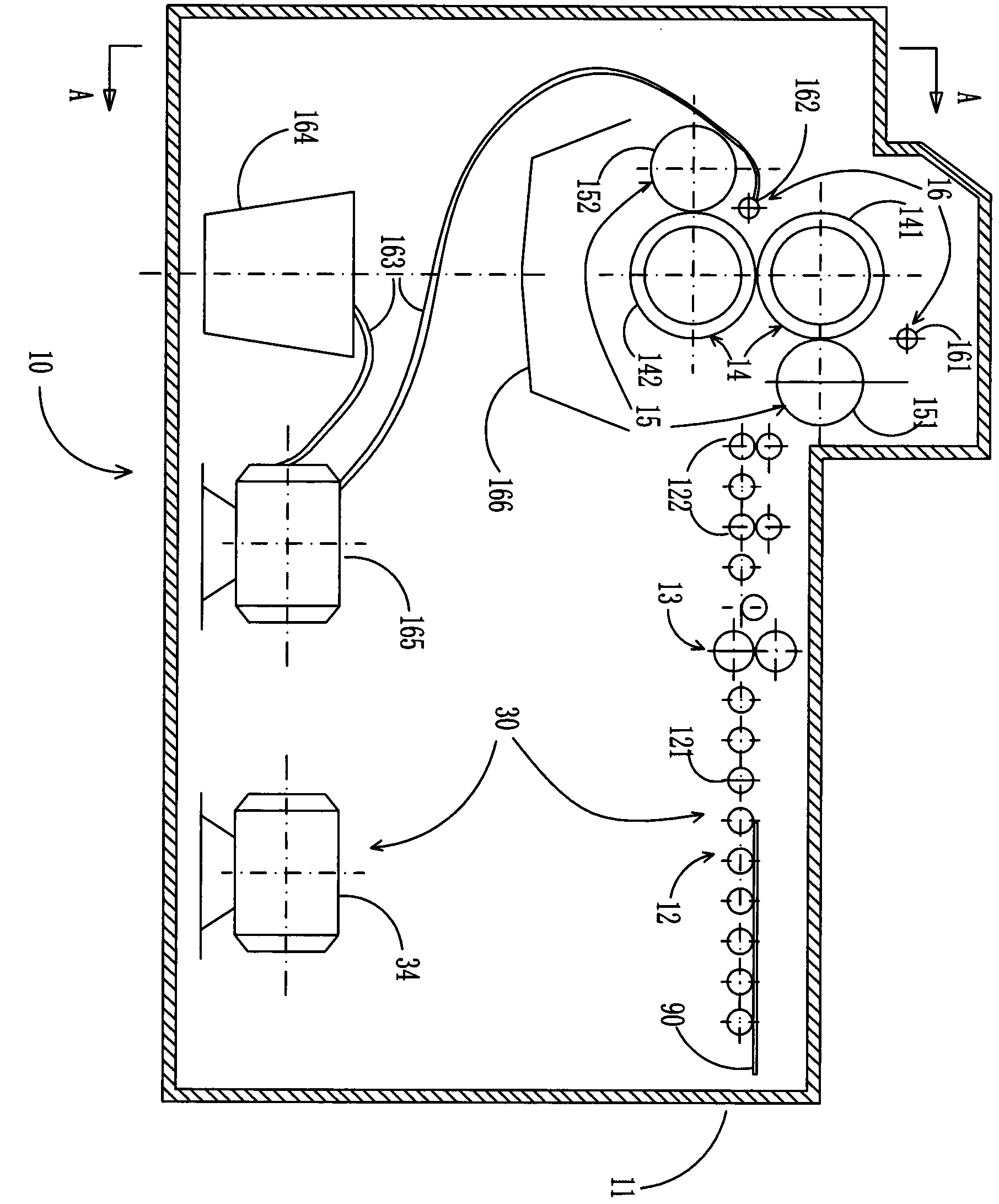

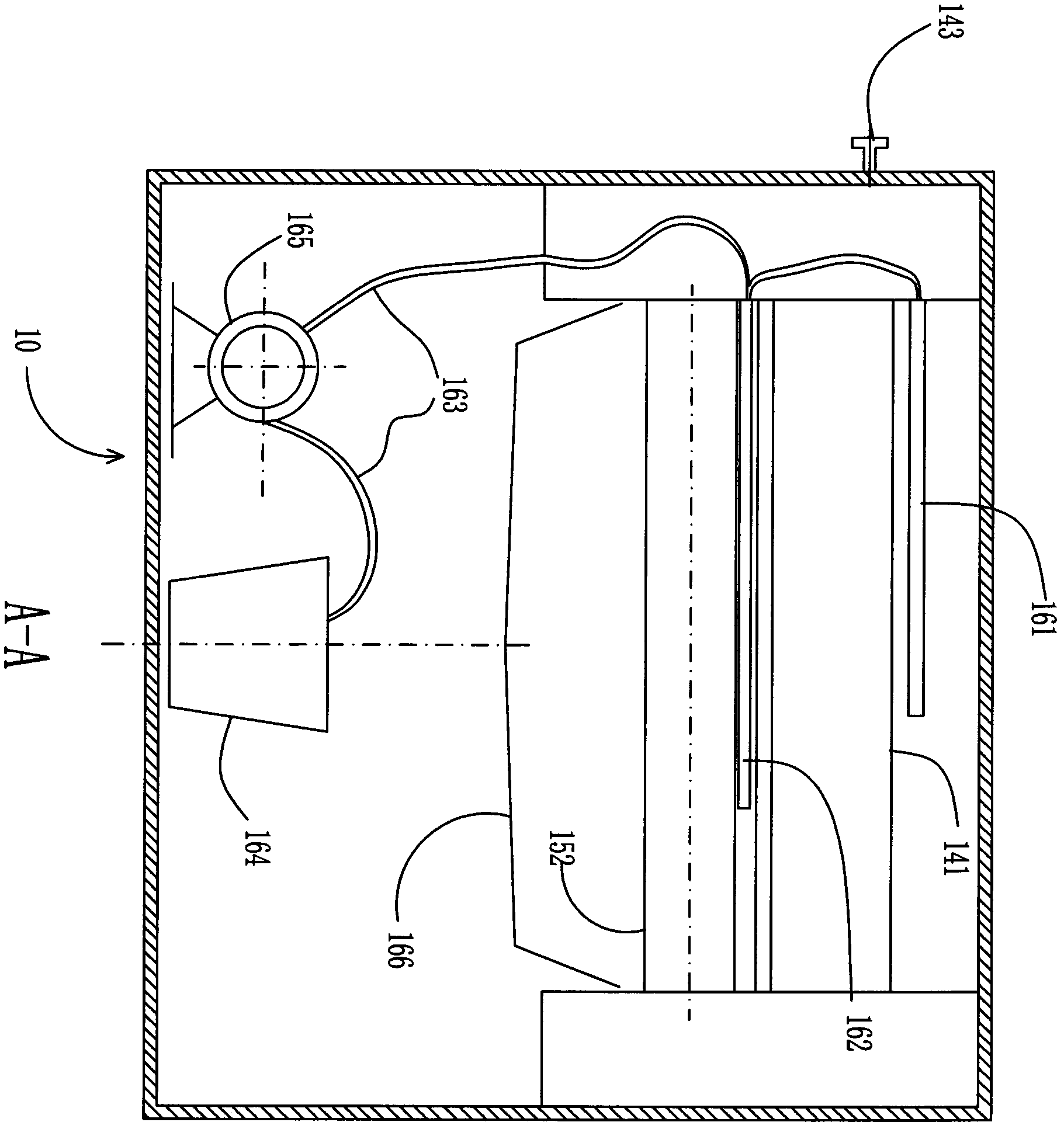

[0030] refer to Figure 1 ~ Figure 4 , take a double-sided circuit board that has been formed with a circuit pattern by etching, the thickness of the copper clad on the circuit board is 36 microns, and send the circuit board 90 into the first solder resist oil coating device 10. like figure 1 , the wiring board 90 is placed at the front end of the coating device 10 ( figure 1 On the roller type feeding mechanism 12 on the right side of the middle), the circuit board 90 is conveyed forward by the roller type feeding mechanism 12, and when passing through the dust sticking wheel 13, the dust sticking wheel 13 sticks and removes the dust on the circuit board 90 , and the circuit board 90 is sent between the first upper coating roller 141 and the first lower coating roller 142 of the first coating roller assembly by two sets of feeding rollers 122, and the first upper spraying roller of the first oil spray assembly The solder resist oil sprayed from the oil pipe 161 and the firs...

Embodiment 2

[0044] The basic steps and the coating device of the coating process of solder resist oil are the same as in Example 1, the difference is that the thickness of the copper clad of the circuit board used is 50 microns, after the first coating of solder resist oil, after measurement, the The thickness of the solder resist oil on the surface of the circuit board in the area with dense lines is 5 microns, and the thickness of the solder resist oil on the surface of the circuit board in other areas is 13 microns. After the second coating, the thickness of the solder resist oil on the surface of the circuit board in the densely populated area is 15 microns, and the thickness of the solder resist oil on the surface of the circuit board in other areas is 21 microns, which has reached the specified requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com