Thickness compensation method and compensation block for fuel rod end plug welding line X ray transillumination process

A technology of thickness compensation and fuel rods, applied in nuclear engineering, material analysis using radiation, nuclear reactor monitoring, etc., can solve the problems of insufficient detection sensitivity and large thickness of X-ray transillumination, so as to improve detection sensitivity and reduce transillumination Thickness, the effect of avoiding the interference of scattered rays

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

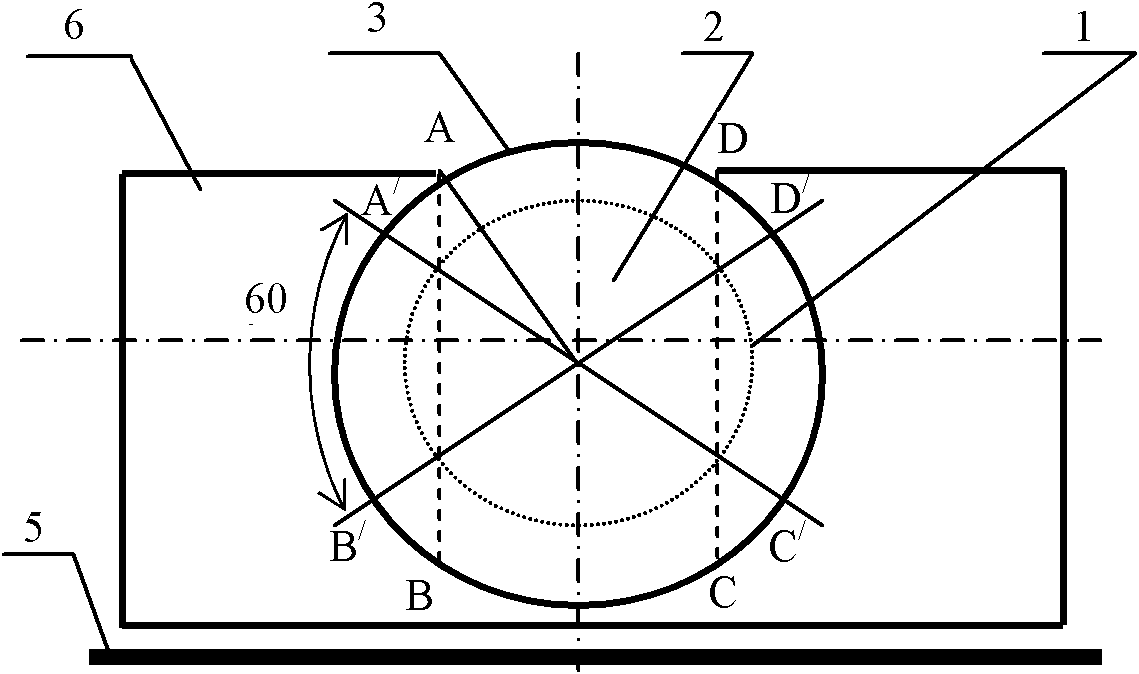

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

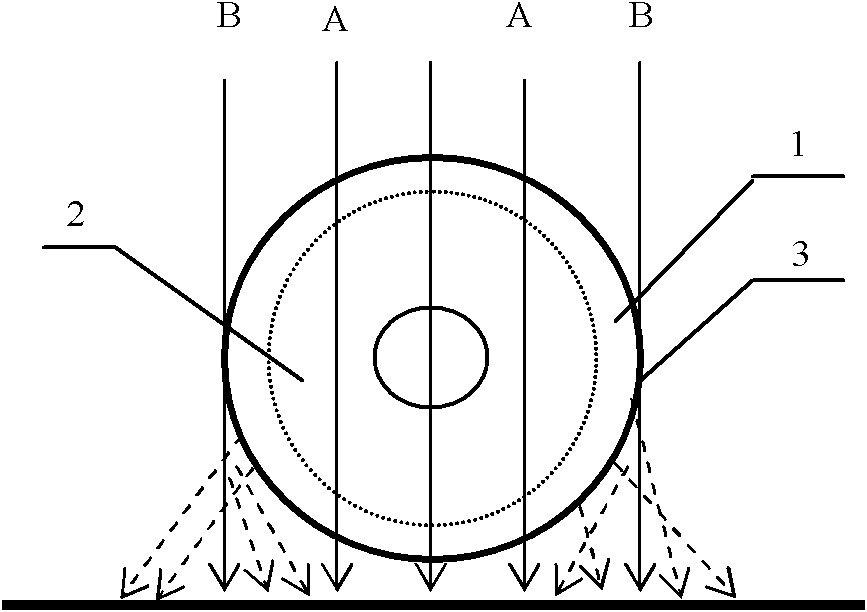

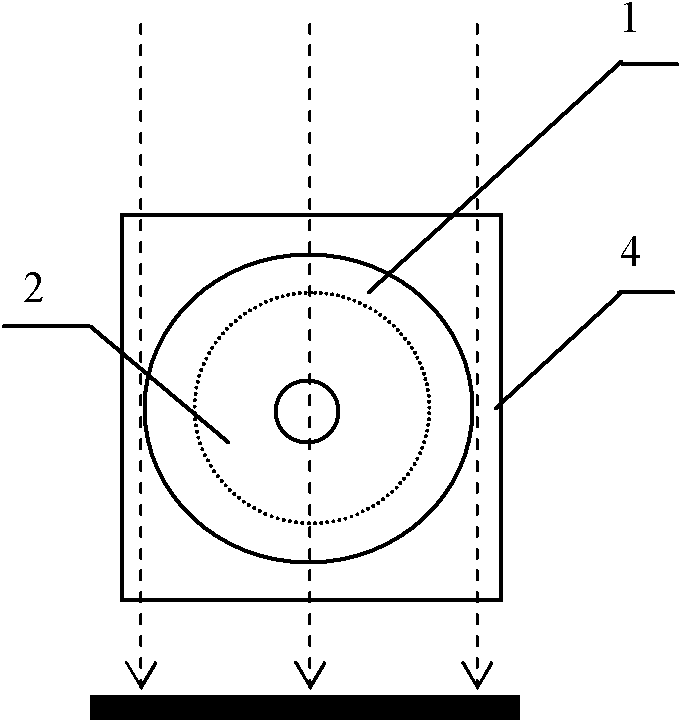

[0022] X-ray real-time imaging non-destructive testing method is usually used for nuclear fuel rod end plug welds. X-ray real-time imaging is to transmit the X-ray generated by a high-power X-ray machine to the weld of the end plug of the nuclear fuel rod, and use a digital flat panel detector to receive the X-ray transmitted through the end plug weld in real time and convert it into a digital image. The signal is transmitted to a special data processing microcomputer, which processes the data through special detection software, and displays the X-ray transillumination image of the nuclear fuel rod end plug weld on the computer screen in real time, and various defects in the weld will be displayed on the image in real time It shows that the microcomputer automatic processing system uses data processing software to analyze the defect situation through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com