Micro-dynamic ash-discharging ball valve

A micro-power, ball valve technology, applied in valve devices, engine components, cocks including cut-off devices, etc., can solve the problems of large opening torque, difficult manufacturing, sealing failure, etc., to reduce driving torque, transmission effort, and reliable sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

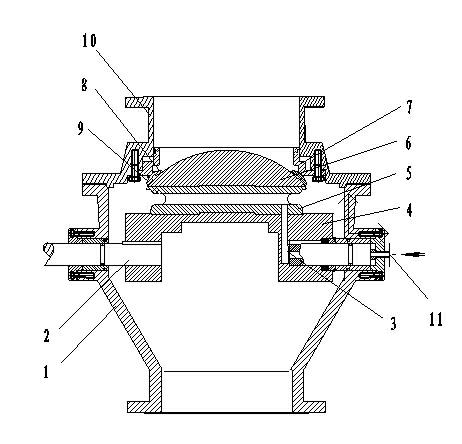

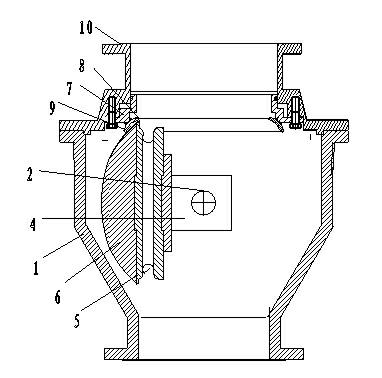

[0023] As shown in the figure, the micro-power ash unloading ball valve of the present invention includes a valve body 1, a valve stem 2, a valve seat 7, and a valve cover 10. Its sphere is a hemisphere 6, and the bottom of the hemisphere 6 is connected with the expansion bag 5, and the expansion bag 5 is fixed. On the hemispherical bracket 4, the hemispherical bracket 4 is fixedly connected with the valve stem 2, the cavity of the expansion bag 5 is connected with the compressed air pipeline, and a double-sided stainless steel sealing ring is fixed on the valve seat 7, and the double-sided stainless steel sealing ring is connected to the surface of the hemisphere 6. touch.

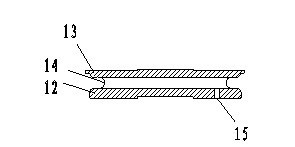

[0024] As shown in the figure, the expansion package 5 is a metal structure expansion package 5, and the bottom surface 12 and the top surface 13 of the expansion package 5 are parallel circular metal flat blind plates, and the middle is connected by an elastic thin metal ring 14, and the thin metal circle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com