Hot-blast furnace combined grate suitable for stacking checker bricks with different structures

A checker brick and furnace grate technology is applied in the field of combined furnace grate of a hot blast stove, and can solve problems such as checker brick breakage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

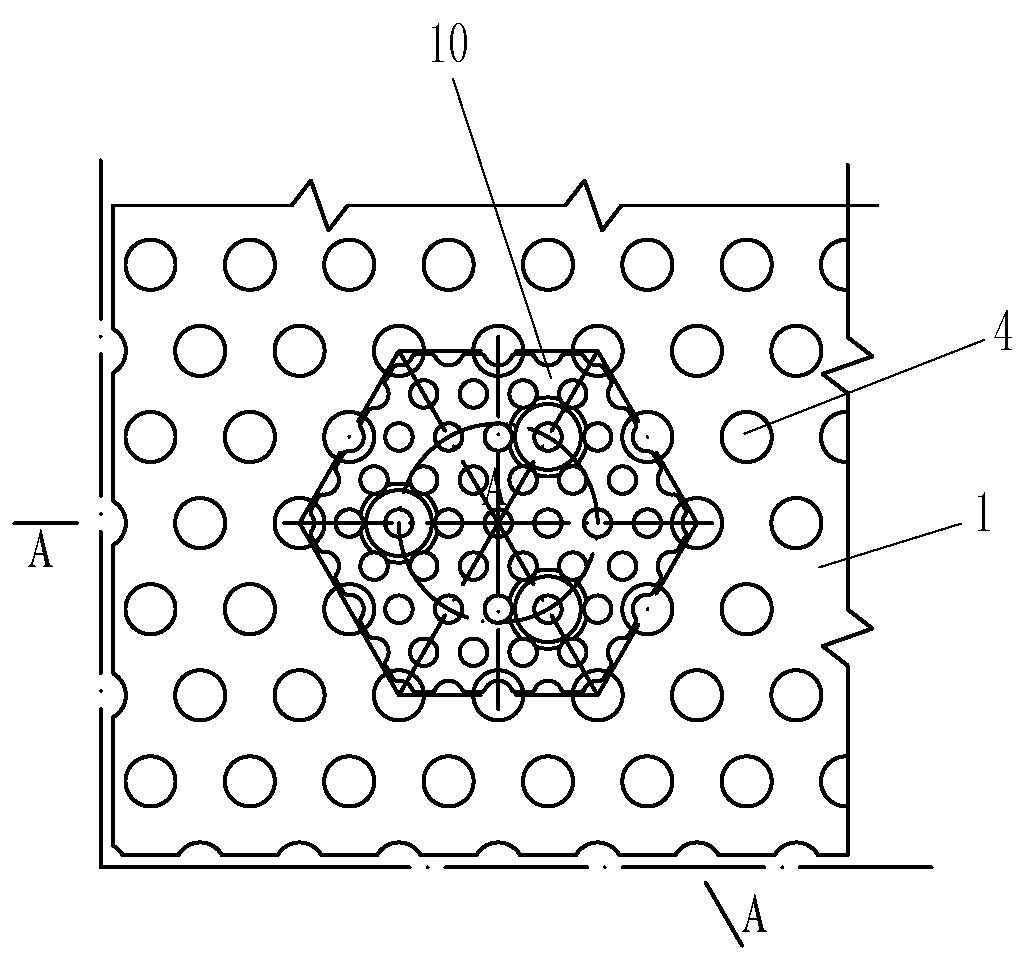

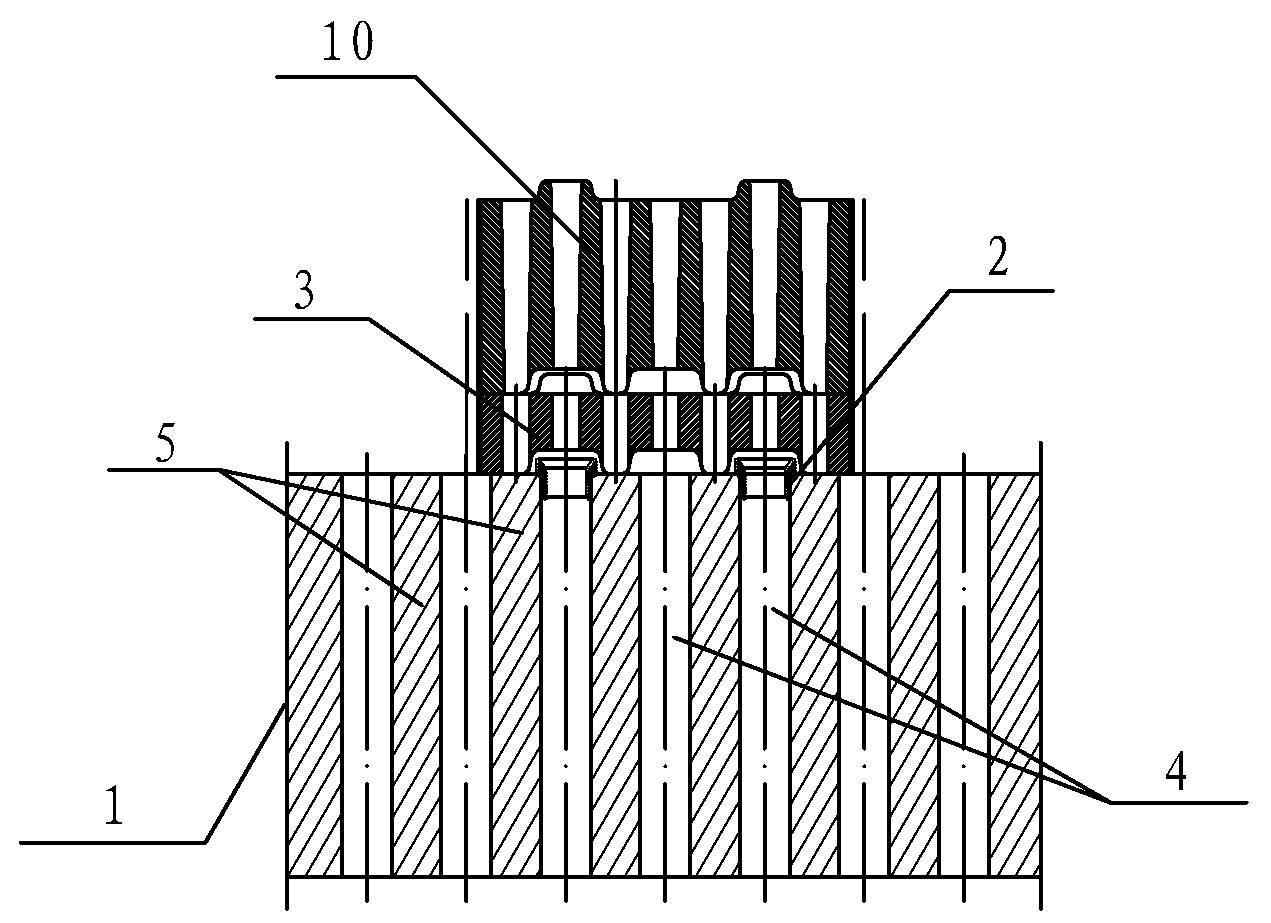

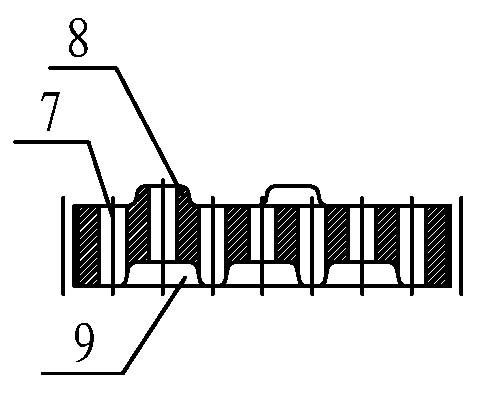

[0014] Depend on Figure 1-Figure 7 Given, the present invention is made up of a plate-shaped grate body 1, a T-shaped positioning sleeve 2 and a checker brick transition block 3, and the grate body 1 is provided with circular through holes 4 evenly arranged at intervals of regular triangles. , the hole walls 5 between the holes all become the load-bearing structure of the grate, and the positioning sleeve 2 is a T-shaped cylindrical body composed of a large ring sleeved on one end of a small cylinder, and the small cylinders are equidistant The intervals are placed in the circular through holes 4 evenly arranged on the grate body 1, the lower end face 6 of the large ring is placed on the hole wall 5 of the grate body, and the positioning on the grate body 1 is placed at intervals. The sleeve 2 forms regularly arranged position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com