Small cantilever-type fully-automatic loading and unloading crane pipe

A fully automatic, cantilever-type technology, applied in packaging, dispensing devices, transportation and packaging, etc., can solve the problems that threaten the safety production of petrochemical enterprises, easily generate sparks in transmission, and affect the health of loading personnel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

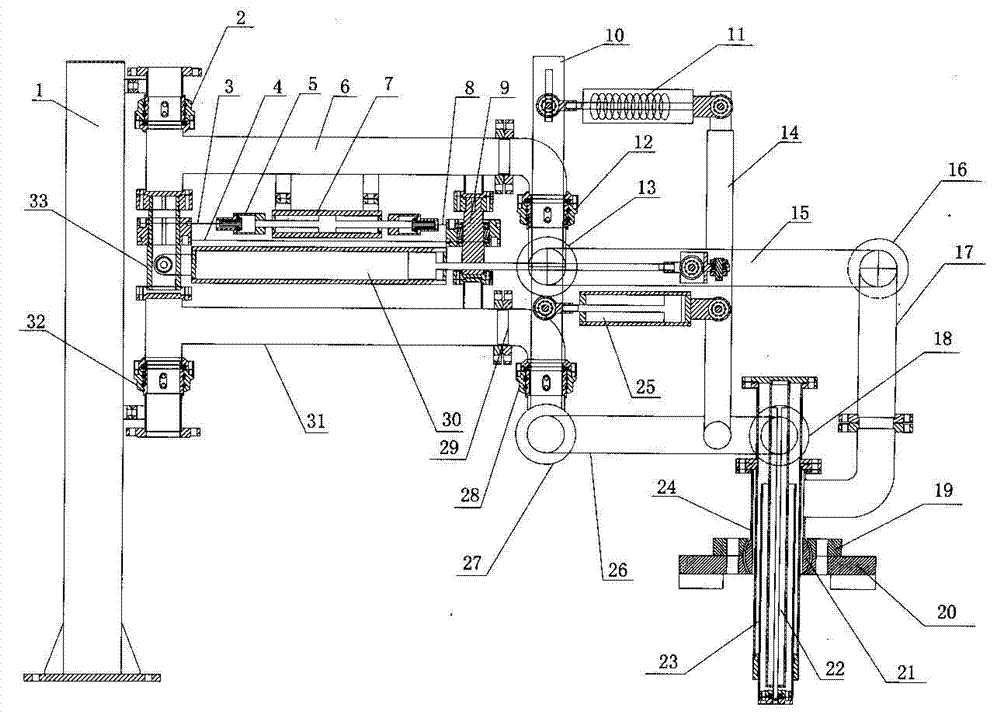

[0023] Such as figure 1 As shown, the cantilever type fully automatic loading and unloading small crane tube includes a column 1, a liquid phase crane tube, a gas phase crane tube and a vertical tube 24, and the liquid phase crane tube is composed of a flange 29, an elbow, and a second horizontal The inner arm 31 and the outer arm 26 which are connected together by the rotary joint 28 and the first up and down rotary joint 27 are formed. The joint 18 is connected with the vertical pipe 24, and a spring cylinder balance device is installed on the outside of the outer arm; the spring cylinder balance device includes a connecting plate A 10, a connecting plate B 14 and a spring cylinder 11, and the lower end of the connecting plate A 10 is connected to the first up and down rotation On the joint, the lower end of the connecting plate B 14 is connected to the outer arm 26, the connecting plate A and the connecting plate B are vertically parallel, the spring cylinder 11 is arranged...

Embodiment 2

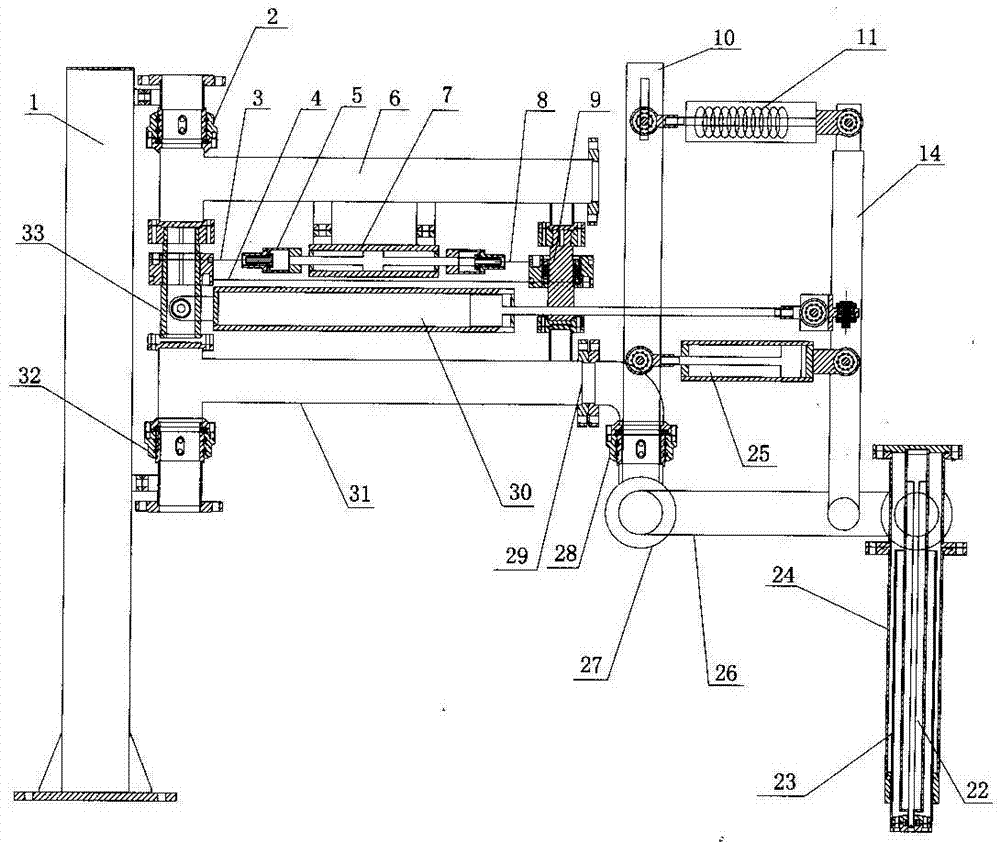

[0035] Such as figure 2 As shown, the cantilever type fully automatic loading and unloading small crane tube includes a column 1, a liquid phase crane tube and a vertical tube 24, and the liquid phase crane tube is composed of a flange 29, an elbow, a second horizontal rotary joint 28, The inner arm 31 and the outer arm 26 that are connected together by the first up and down rotary joint 27 are formed, the head end of the inner arm 31 is connected with the column 1 through the first horizontal rotary joint 32, and the tail end of the outer arm 26 is connected with the vertical column through the second up and down rotary joint 18. The tube 24 is connected, and a spring cylinder balancing device is installed on the outer side of the outer arm; the spring cylinder balancing device includes a connecting plate A 10, a connecting plate B 14 and a spring cylinder 11, and the lower end of the connecting plate A 10 is connected to the first upper and lower rotary joint, connected The...

Embodiment 3

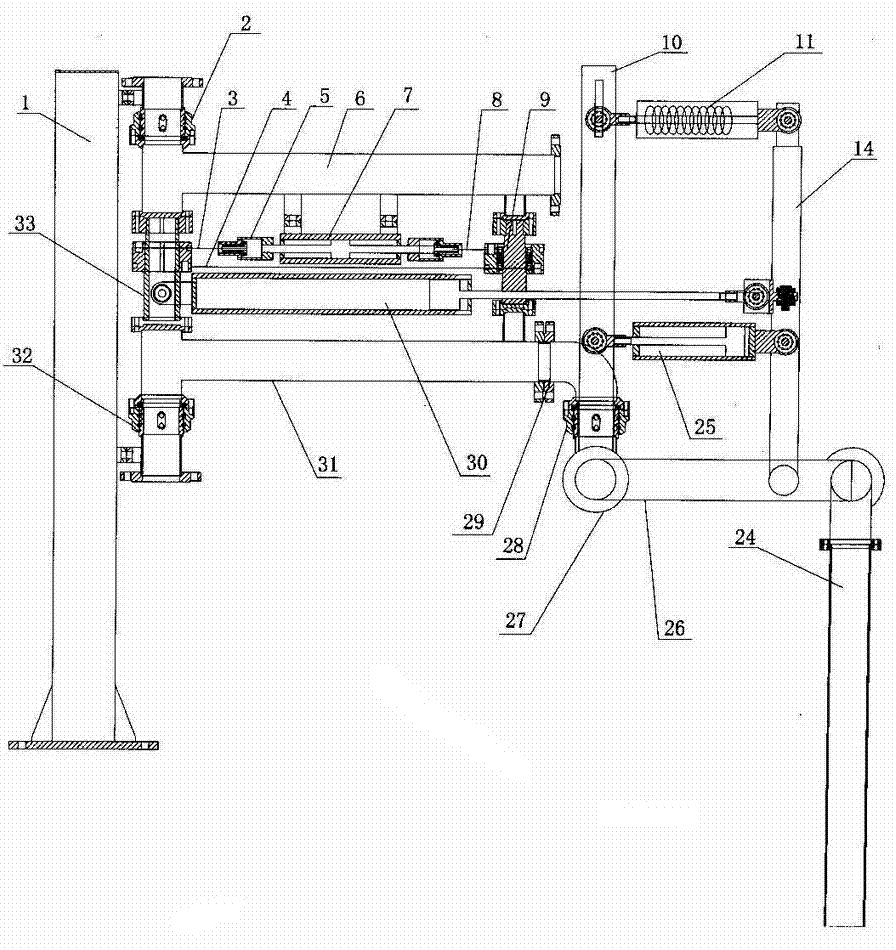

[0040] Such as image 3 As shown, the structure of the cantilever type fully automatic loading and unloading small crane tube is basically the same as that of the small crane tube in Embodiment 2, the only difference is that there is no telescopic tube inside the vertical tube 24, and a vertical telescopic cylinder that controls the vertical movement of the telescopic tube .

[0041] The working process of the cantilever type fully automatic loading and unloading of the small crane tube in this embodiment is the same as the operation process of the liquid phase crane tube controlled by the bidirectional cylinder, the horizontal telescopic cylinder and the lifting cylinder in the first embodiment.

[0042] In this embodiment, the cantilever-type fully automatic loading and unloading small crane tube is suitable for petroleum and chemical enterprises to pack crude oil, residual oil, bitumen and other liquids with high density, non-volatile and non-polluting to the environment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com