Sealing device of rubber roller bearing

A technology of sealing device and rubber roller, which is applied in the direction of engine sealing, grinding device, mechanical equipment, etc., can solve the problems of complex replacement of bearings, short service life, difficulties, etc., and achieve improved work efficiency, good sealing effect and extended service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

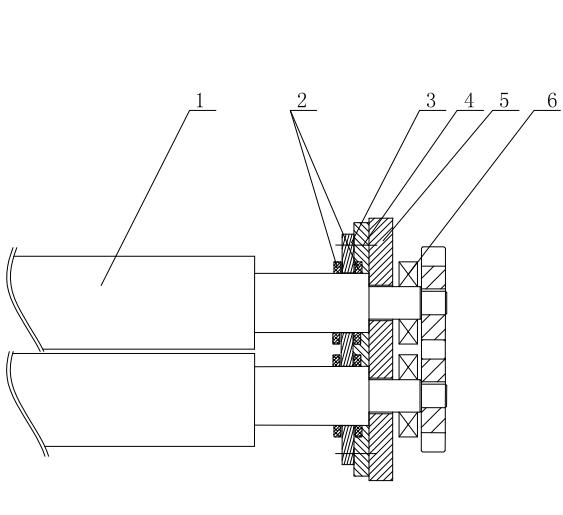

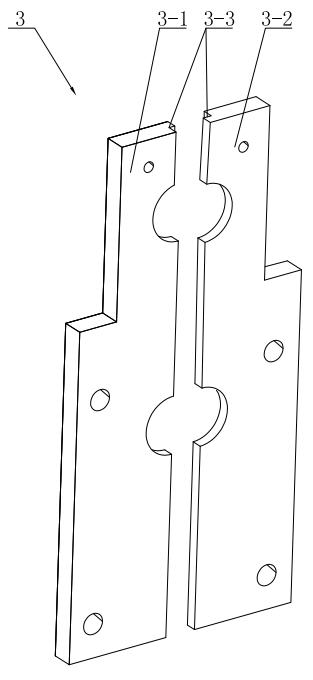

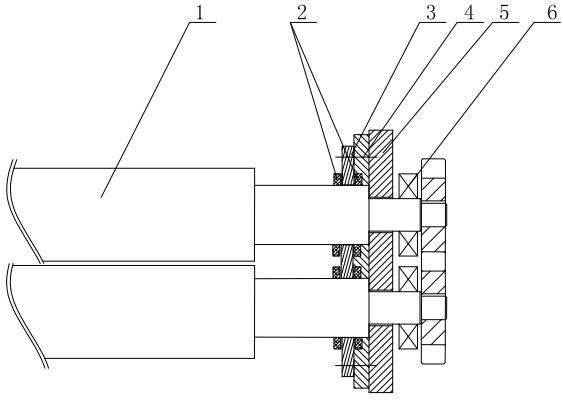

[0014] Such as figure 1 As shown, in the sealing device of the rubber roller bearing according to the present invention, the two ends of the rubber roller 1 are respectively installed in the grooves of the bracket baffle 5, and the two ends of the rubber roller 1 are supported by bearings 6, and the inner sides of the bracket baffle 5 at both ends are The steel plates 4 are respectively connected, and the steel plates 4 are connected to the bracket baffle 5 through fasteners; a pair of rubber rings 2 are set on both ends of the rubber roller 1 and are located on the inner side of the steel plates 4, and a plastic plate 3 is arranged between the rubber rings 2. The plastic plate 3 is connected and fixed with the steel plate by fasteners; figure 2 As shown, the plastic plate 3 is composed of two symmetrical plates 3-1 and 3-2, and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com