Vehicle body correcting machine and control system mounted on base of correcting machine

A control system and correction machine technology, applied in the direction of lifting devices, lifting frames, etc., can solve the problems of increasing secondary installation costs, increasing site area, intermittent control process, etc., and achieve the goal of saving manpower, simple layout, and shortening the movement drop Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Referring to the accompanying drawings, specific embodiments of the present invention are given below to further describe the present invention.

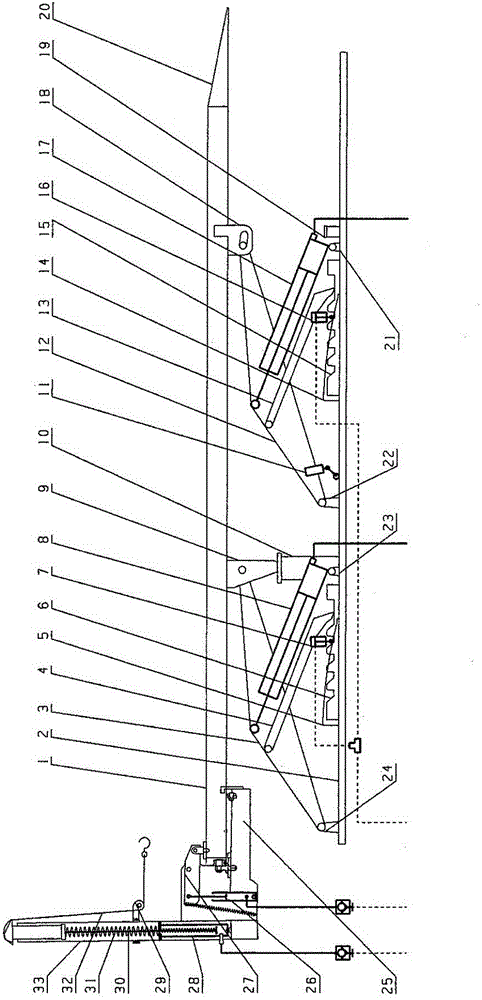

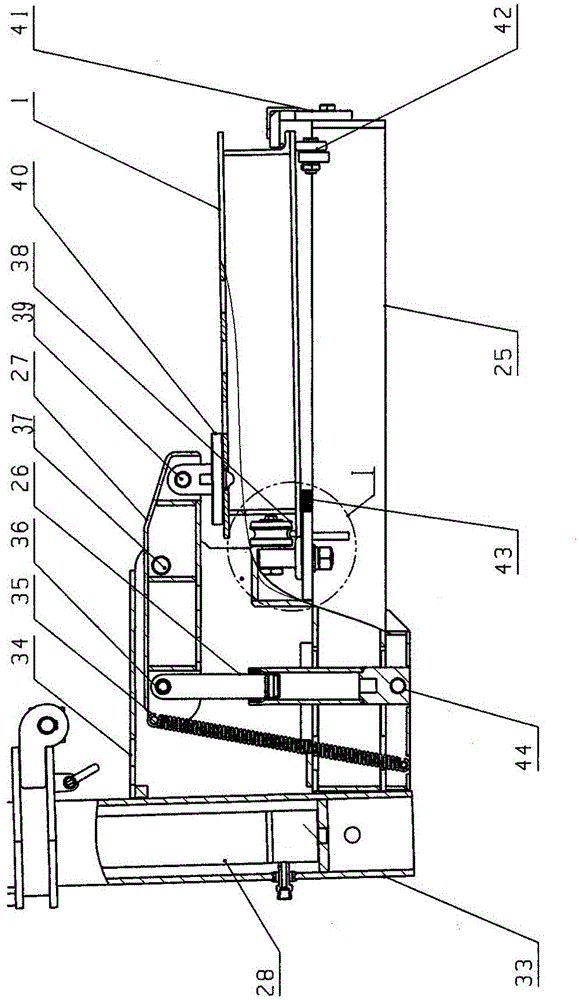

[0055] Such as figure 1 , the car body correction machine of the present invention includes a flexible lifting mechanism and a pull tower, and the pull tower is locked and installed on the platform 1 including the flexible lifting mechanism through the pull tower quick locking mechanism.

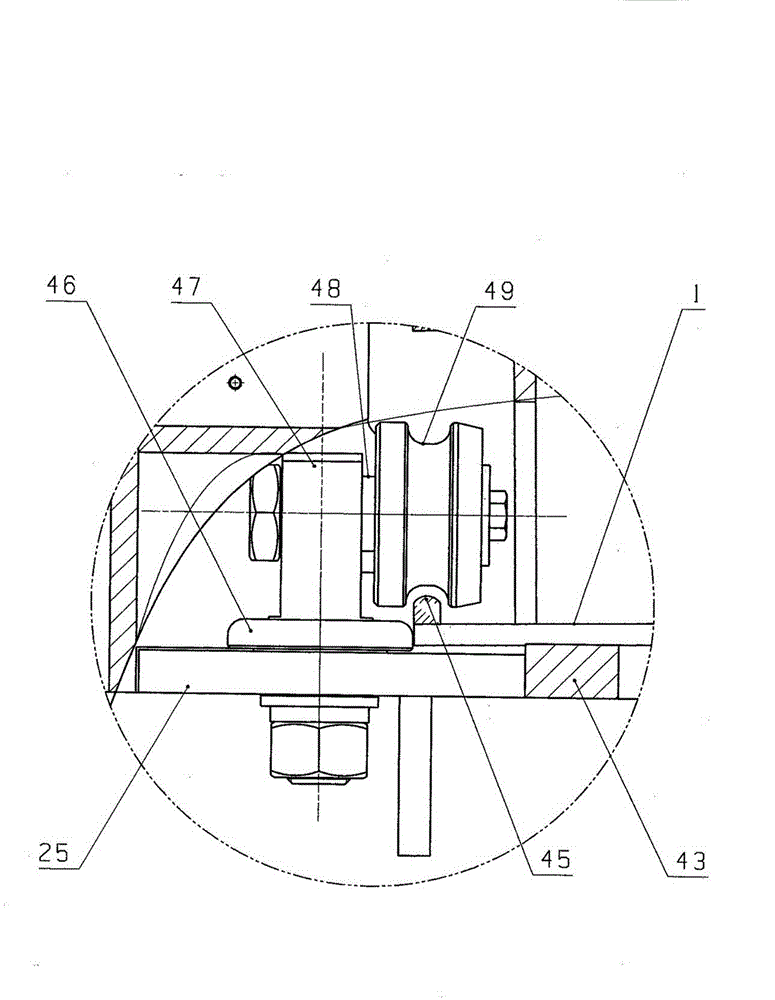

[0056] The pull tower comprises a pull tower cross arm 25 and a tower column 33 installed on the pull tower cross arm 25, a stretching oil cylinder 28 is installed at the inner bottom of the tower column 33, and the stretch oil cylinder 28 is connected with a push rod 30. A ring sleeve 29 is installed on the outer circle of the ring sleeve 29, and the stretch chain 32 with a pull hook passes through the sprocket wheel on the ring sleeve 29, and is fixed on the push rod 30 through the chute on the top surface of the push rod 30, and also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com