Method for removing impurity oxide layer from polluted accelerating tube

A technology of accelerating tube and oxide layer, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning hollow objects, etc., can solve the problems of high processing accuracy and smoothness, pulse power loss of accelerating tube, complex cavity structure, etc. Achieve significant social and economic benefits, recover economic losses, and have a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A method for decontaminating the oxide layer of the polluted post-acceleration tube of the present invention, comprising the following steps:

[0020] 1. Fix the acceleration tube vertically, place the axis of the acceleration tube perpendicular to the horizontal plane (the neutral acceleration tube already in use meets the requirements), and the input end of the acceleration tube faces upward.

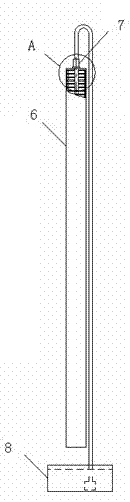

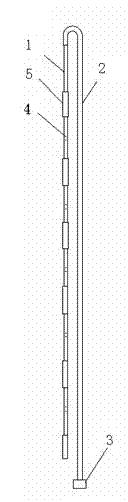

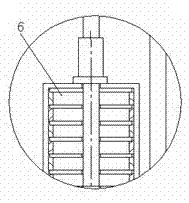

[0021] 2. Put the bottom of the cleaning tool in the plastic tank 8 equipped with cleaning liquid, pump the cleaning liquid into the metal pipe 1 of the cleaning tool through the water pump 3; insert the lower end of the metal pipe of the cleaning tool into the acceleration tube 6, and accelerate The inner wall of the lumen is cleaned. figure 1 It is a schematic diagram of cleaning tool connection in the present invention, figure 1 Middle 7 is connecting flange. The connecting flange fixes the metal tube 1 at the center of the cavity of the accelerating tube. figure 2 It is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com