Flotation method for waste residue of phosphate gypsum

A phosphogypsum and waste residue technology is applied in the field of positive flotation of calcium sulfate dihydrate to achieve the effects of reducing impurity content, reducing pollution and facilitating large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

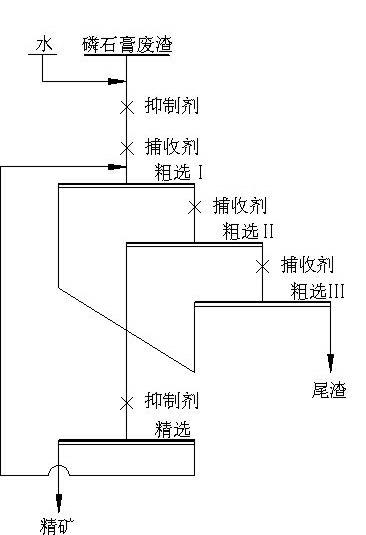

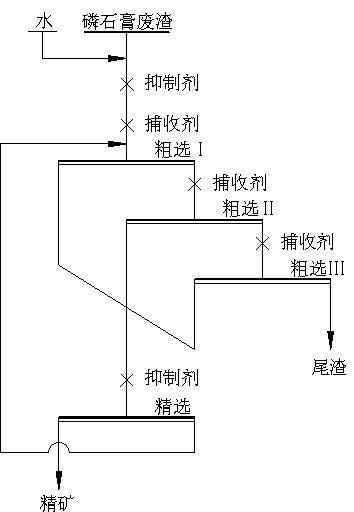

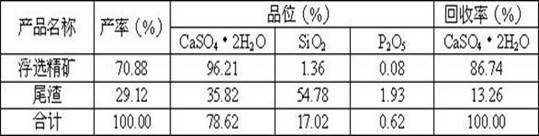

[0013] Embodiment 1, a flotation method of phosphogypsum waste residue, the steps are as follows: add water to the phosphogypsum waste residue, control the mass concentration of the pulp at 15%, and perform flotation in a flotation machine; flotation adopts 2 times of roughing and 1 beneficiation operation; add inhibitor 1.5kg / t phosphogypsum waste residue, collector 100g / t phosphogypsum waste residue for rough separation Ⅰ operation, and then carry out another roughing operation, and add collector 50g / t phosphogypsum waste residue in each roughing operation; the roughing tank is tailings; after merging roughing foam products, add inhibitor 0.1kg / t The phosphogypsum waste slag is selected for one time; the selected foam is high-quality phosphogypsum for flotation concentrate, and the product in the selected tank is returned to roughing as middle ore Ⅰ operation; the inhibitor is water glass; the collector is acetate or hydrochloride of alkyl fatty amine with 8 to 18 carbon ato...

Embodiment 2

[0014] Embodiment 2, a flotation method of phosphogypsum waste residue, the steps are as follows: add water to the phosphogypsum waste residue, control the mass concentration of the pulp at 30%, and perform flotation in a flotation machine; flotation adopts 5 times of roughing and 2 beneficiation operations; add inhibitor 3.5kg / t phosphogypsum waste residue, collector 300g / t phosphogypsum waste residue for rough separation Ⅰ operation, and then 4 times of roughing operations, and each roughing operation is added with collector 150g / t phosphogypsum waste residue; the roughing tank is tailings; after merging roughing foam products, add inhibitor 1kg / t phosphorus The gypsum waste residue is selected twice; the selected foam is flotation concentrate high-quality phosphogypsum, and the product in the selected tank is returned to roughing as middle ore Ⅰ operation; the inhibitor is water glass; the collector is acetate or hydrochloride of alkyl fatty amine with 8 to 18 carbon atoms....

Embodiment 3

[0015] Embodiment 3, a flotation method of phosphogypsum waste residue, the steps are as follows: add water to the phosphogypsum waste residue, control the mass concentration of the pulp at 22%, and perform flotation in a flotation machine; flotation adopts 3 times of roughing and one beneficiation operation; add inhibitor 2.5kg / t phosphogypsum waste residue, collector 200g / t phosphogypsum waste residue for rough separation Ⅰ operation, and then carry out 2 roughing operations, and add collector 100g / t phosphogypsum waste residue in each roughing operation; the roughing tank is tailings; after merging roughing foam products, add inhibitor 0.5kg / t The phosphogypsum waste slag is selected for one time; the selected foam is high-quality phosphogypsum for flotation concentrate, and the product in the selected tank is returned to roughing as middle ore Ⅰ operation; the inhibitor is water glass; the collector is acetate or hydrochloride of alkyl fatty amine with 8 to 18 carbon atoms...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com