Method for improving grade of rutile through microwave pretreatment-magnetic separation combined process

A combined process and pretreatment technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of not meeting the requirements of titanium dioxide raw materials into the furnace, and achieve low cost, good environment and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

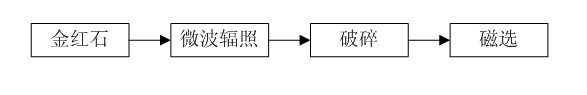

[0014] Example 1: according to figure 1 As shown in the process flow, 100g of natural rutile ore is subjected to microwave irradiation for 20s, the microwave power is 1kW, and the microwave frequency is 2350MHz, and then the ore grinding treatment is carried out. The ore grinding time is 40min. After grinding, the rutile ore particle size is below 200 mesh. 80g, the rutile ore after grinding is put into the magnetic separation equipment with current intensity of 3A, and magnetic separation is carried out to obtain iron concentrate and enriched rutile ore. The grade of rutile after magnetic separation is 90.12%, which is higher than that before magnetic separation. An increase of 2.58%.

Embodiment 2

[0015] Example 2: according to figure 1 As shown in the process flow, 150g of artificial rutile ore is subjected to microwave irradiation for 60s, the microwave power is 3kW, and the microwave frequency is 2550MHz, and then the ore grinding treatment is carried out, and the grinding time is 60min. After grinding, the rutile ore particle size is below 200 mesh. 128g, put the rutile ore after grinding into the magnetic separation equipment with a current intensity of 5A, and carry out magnetic separation to obtain iron concentrate and enriched rutile ore. The grade of rutile after magnetic separation is 91.25%, which is higher than that before magnetic separation. An increase of 3.71%.

Embodiment 3

[0016] Embodiment 3: press figure 1 As shown in the process flow, 200g of natural rutile ore is subjected to microwave irradiation for 40s, the microwave power is 2kW, and the microwave frequency is 2450MHz, and then the ore grinding treatment is carried out, and the grinding time is 50min. After grinding, the rutile ore particle size is below 200 mesh. 180g, the rutile ore after grinding is put into the magnetic separation equipment with a current intensity of 4A, and magnetic separation is carried out to obtain iron concentrate and enriched rutile ore. The grade of rutile after magnetic separation is 90.87%, which is higher than that before magnetic separation. An increase of 3.33%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com