Refining low-slag-quantity operating process

An operation process and small slag volume technology, which is applied in the field of refining small slag volume operation process, can solve the problems of high production cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

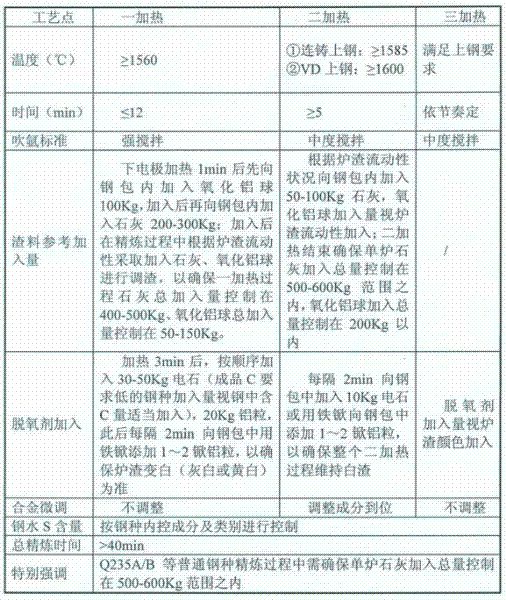

[0006] The refining small slag amount operation process of the present invention includes two parts, that is, the slagging agent is divided into two parts and added: a part of the slagging agent is added after the converter is tapped, and a part of the slagging agent is added when the molten steel enters refining; adding lime in the converter 100-200kg / furnace, add lime 500-600kg / furnace and alumina balls ≤150kg / furnace during refining.

[0007] This process is mainly divided into two parts; one part is completed after the converter puts steel, and the other part is completed when the molten steel enters refining.

[0008] 1. Converter process

[0009] During the tapping process, only lime is added to the ladle, specifically:

[0010] ① For ordinary steel, 100Kg of lime is added to the ladle during the tapping process of the converter;

[0011] ② For the variety steel, 200Kg of lime is added from the high-level silo during the tapping process of the converter.

[0012] 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com