Method for preparing cyclopentanol through hydration of cyclopentene

A cyclopentene hydration and cyclopentene technology, which is applied in the preparation of hydroxyl addition and organic chemistry, can solve the problems of reduced activity of strongly acidic cation exchange resins, large circulation of raw material cyclopentene, and low reaction conversion rate. Achieve the effects of fewer types, improved mutual solubility, and less dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

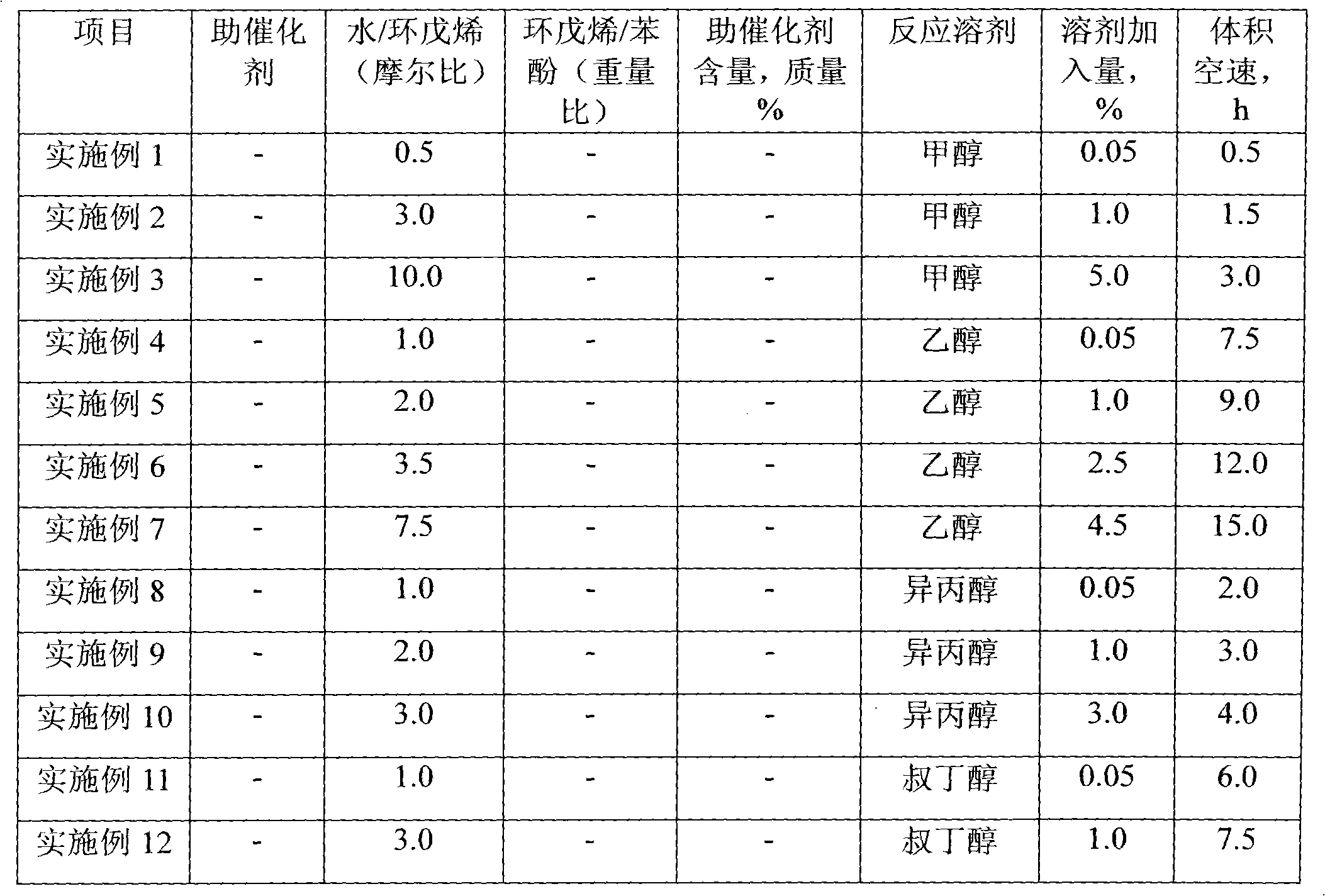

Embodiment 1~32

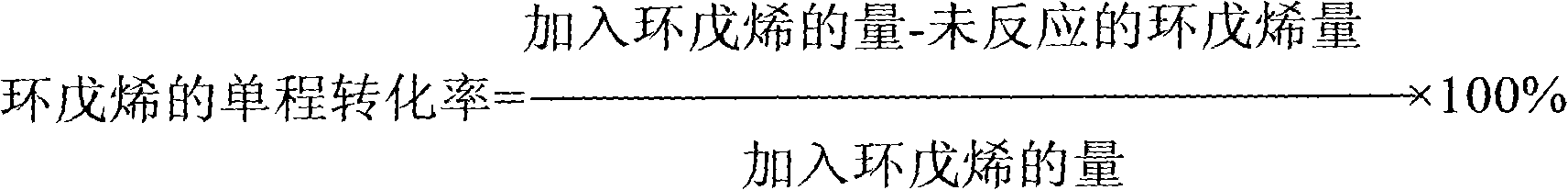

[0011] The hydration reaction is carried out in a stainless steel reactor of Φ18mm×1200mm, and 30ml of DNW-II temperature-resistant resin catalyst produced by Dandong Mingzhu Special Resin Co., Ltd. is loaded into the reactor, and the top and bottom of the reactor are respectively loaded with a diameter of Φ0. 5mm ~ 1.2mm quartz sand, after the reactor is installed, replace it with nitrogen three times, and pass the airtight test, put cyclopentene, water and C 1 ~C 4 The low-carbon alcohol is sent to the preheater according to the specified ratio by a metering pump, and the material is preheated to 100°C to 200°C. The preheated material enters the hydration reactor for hydration reaction, the reaction temperature is controlled at 100°C-200°C, and the reaction pressure is 1.0MPa-6.0MPa. In order to compare the reaction effects, each embodiment and comparative example were carried out at 130° C. and 2 MPa. Unreacted cyclopentene is recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com