Method for producing low iron aluminum sulfate by utilization of coal gangue

A low-iron aluminum sulfate and coal gangue technology, which is applied in the removal of aluminum sulfate, aluminum-sulfur compounds, and solid waste, etc., can solve the problem of no public reports of low-iron aluminum sulfate, fine coal gangue grinding particle size, and low product quality grade. and other problems, to achieve the effect of reducing aluminum loss, less aluminum loss and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

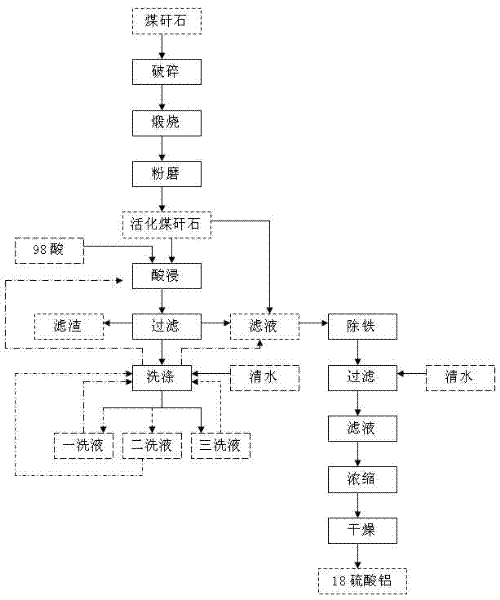

Image

Examples

Embodiment 1

[0039] Example 1: Al 2 o 3 30kg of coal gangue slag with >25% and total iron 2 o 3 , TFe content were 31.57% and 6.16%.

[0040] The following process steps are adopted to produce low-iron aluminum sulfate from coal gangue:

[0041] 1. First pickling

[0042] Get 2000g of activated gangue slag in a 1000ml three-necked flask, add 4050g of water, put it into a water bath, and finally add 1950g of sulfuric acid with a concentration of 98%, which is 1.05 times the amount of acid used in theory, and the total liquid-solid ratio of the reactant is 3:1. Control the temperature in the three-neck flask to 95°C, and the reaction time is 3 hours. Filter while hot, replace with 1000ml of water, incorporate into the filtrate, wash with 9000ml of water three times, and keep the lotion for next use. Obtain filtrate and add up to 6520ml, weight 7978g, Al in the analysis filtrate 2 o 3 : Fe=5.7.

[0043] 2. The first iron removal

[0044] Add 570g of fresh coal gangue slag to the ab...

Embodiment 2

[0050] Example 2: Al 2 o 3 30kg of coal gangue slag with >25% and total iron 2 o 3 , TFe content were 26.52.% and 9.17%.

[0051] The following process steps are adopted to produce low-iron aluminum sulfate from coal gangue:

[0052] 1. First pickling

[0053] Get 2000g of activated coal gangue slag in a three-necked flask of 10000ml, add 6284g of water, put it into a water bath, and finally add 1716g of sulfuric acid with a concentration of 98%, which is 1.09 times the amount of acid used in theory, and the total liquid-solid ratio of the reactant is 4:1. Control the temperature in the three-necked flask to 90°C, and the reaction time is 4 hours. Filter while hot, replace with 500ml of water, incorporate into the filtrate, wash with 9000ml of water three times, and keep the lotion for next use. Obtain filtrate and add up to 6715ml, weight 7978g, through analyzing Al in filtrate 2 o 3 : Fe=7.5.

[0054] 2. The first iron removal

[0055] Add 1200g of fresh coal gang...

Embodiment 3

[0061] Example 3: Al 2 o 3 > 25% and total iron 2 o 3 , TFe content were 32.42% and 4.76%.

[0062] The following process steps are adopted to produce low-iron aluminum sulfate from coal gangue:

[0063] 1. First pickling

[0064] Get activated coal gangue slag 2000g in the there-necked flask of 10000ml, add water 3940g, put in the water bath, add 2060g concentration at last and be 98% sulfuric acid, be 1.08 times of theoretically used acid amount, then the total liquid-solid ratio of reactant is 3:1. Control the temperature in the three-neck flask to 93°C, and the reaction time is 3 hours. Filter while it is hot, replace it with 1000ml hot water, merge it into the filtrate, wash it with 9000ml water three times, and keep the lotion for next use. Obtain filtrate and add up to 6550ml, weight 8013g, Al in the analysis filtrate 2 o 3 : Fe=4.2.

[0065] 2. The first iron removal

[0066] Add 700g of fresh coal gangue slag to the above-mentioned first acid leaching filtr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com