Paste for nonaqueous lithium ion battery positive electrode

A slurry technology for lithium-ion batteries and positive electrodes, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as high defect rate in the production process, poor bonding performance of slurry, loss of financial or material resources, etc., and achieve superior adhesion. Cohesion, improve bonding performance, improve the effect of bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

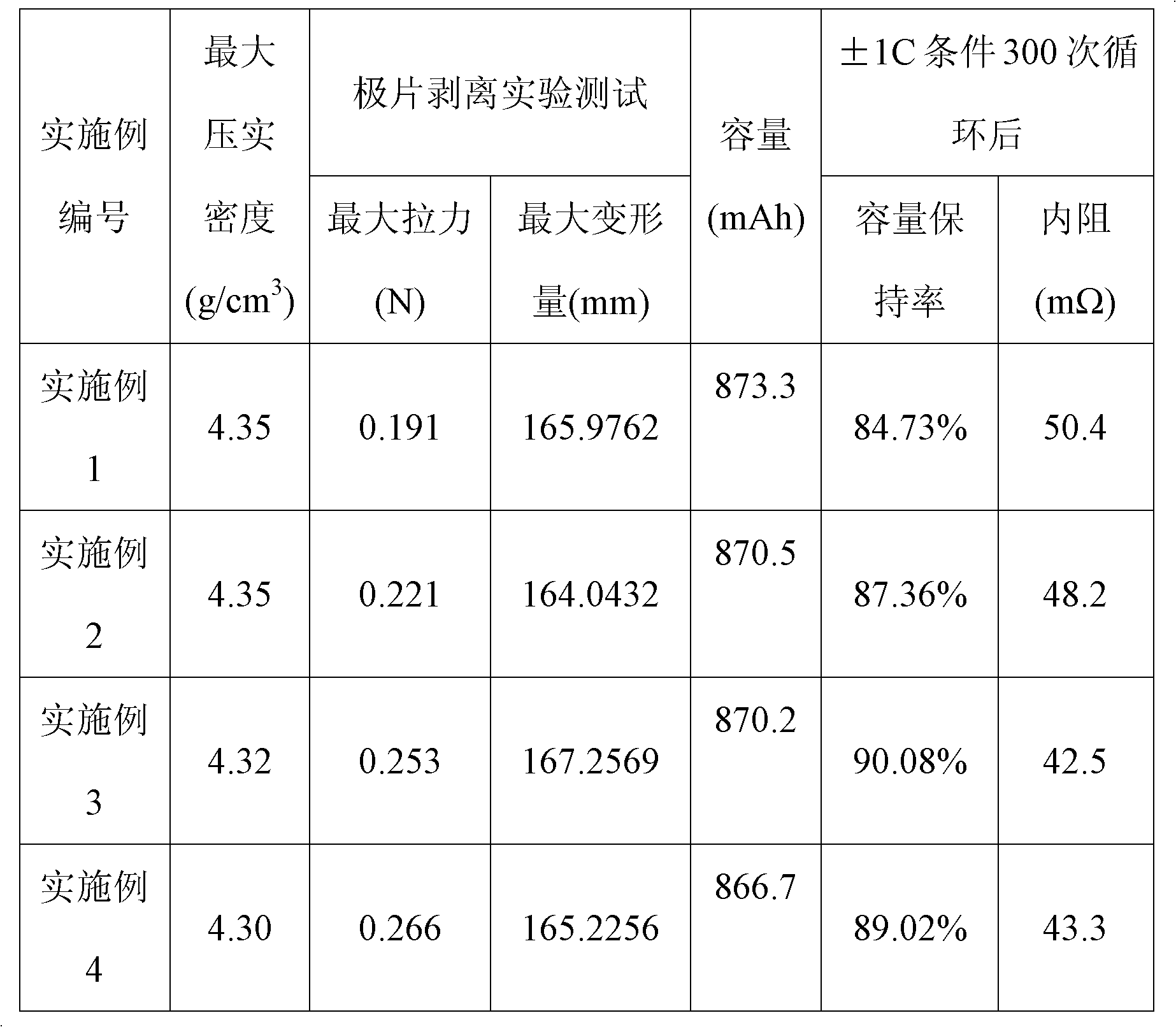

[0034] Lithium cobalt oxide (LiCoO 2) material is used as the positive electrode active material, ultrafine carbon powder is the conductive agent, polyimide is the binder, and N-methylpyrrolidone is the solvent. The ratio of the total mass of the three components of imide to the mass of N-methylpyrrolidone is 100:50, and the percentages of lithium cobaltate, conductive agent, and polyimide in the total mass of the three components are 97.5%. , 2.0%, 0.5%, and then go through the process of coating and sheet-making to make pole pieces. The maximum compaction density test and peeling test are carried out on the pole piece. It is 200mm / min. A single battery with a capacity of 850mAh was prepared using the above pole piece, and the battery was tested for 300 cycles under the condition of ±1C, the voltage range was 3.0-4.2V, the cut-off current of constant voltage charging was 0.05C, and after 300 cycles of testing The internal resistance of the battery. The obtained test result...

Embodiment 2

[0036] The ratio of the total mass of lithium cobaltate, conductive agent, and polyimide to the mass of N-methylpyrrolidone is 100:50, and lithium cobaltate, conductive agent, and polyimide account for the three components respectively The percentage content of the total mass is 97.0%, 2.0%, and 1.0%, and the others are completely made according to the conditions of Example 1, and all tests of Example 1 are carried out, and the obtained test results are shown in Table 1.

Embodiment 3

[0038] The ratio of the total mass of lithium cobaltate, conductive agent, and polyimide to the mass of N-methylpyrrolidone is 100:50, and lithium cobaltate, conductive agent, and polyimide account for the three components respectively The percentage content of the total mass is 96.5%, 2.0%, 1.5%, and the others are made completely according to the conditions of Example 1, and all tests of Example 1 are carried out, and the obtained test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com