On-site full-automatic pressure calibrator

A fully automatic and calibrator technology, which is applied to the measurement of fluid pressure, instruments, machines/engines, etc. It can solve problems such as inability to calibrate, pressure controllers that cannot be carried, and pressure controllers that are large in size and externally connected to gas cylinders. Improve work efficiency, reduce its own weight and volume, and reduce the effect of weight and volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

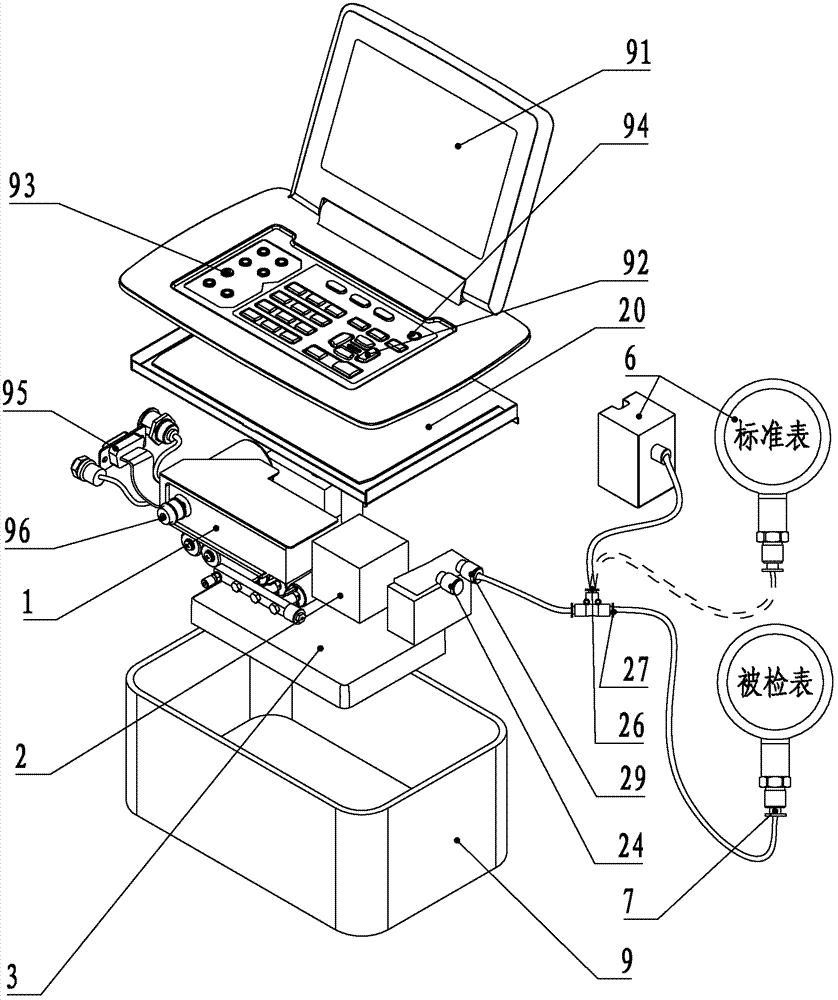

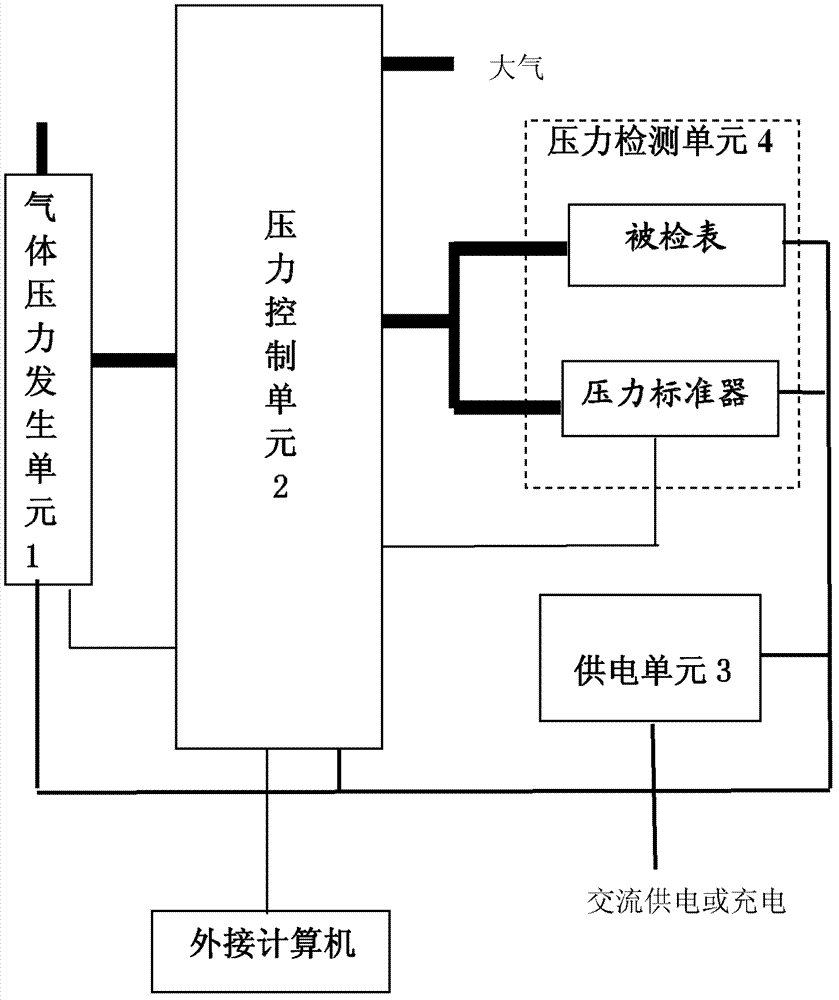

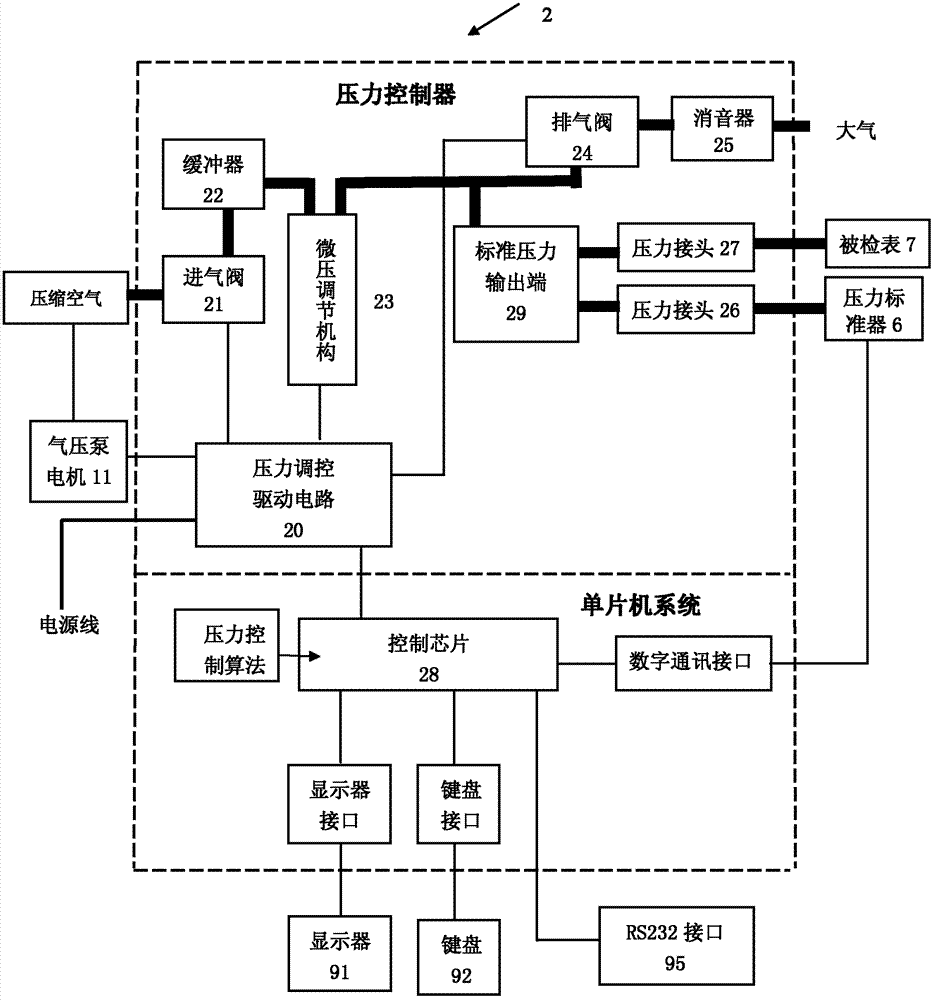

[0029] see figure 1 , figure 2 and image 3 The on-site fully automatic pressure calibrator provided by the present invention includes a housing 9, a gas pressure generating unit 1, a pressure control unit 2, a power supply unit 3 and a pressure detection unit 4 respectively assembled in the housing 9, placed in The display screen 91 and keyboard 92 at the uppermost end of the casing 9 and the conveniently used and properly distributed electrical signal output holes 93, power switch 94, RS232 interface 95, etc. Wherein, the gas pressure generating unit 1 is provided with a gas path input port (intake port) 96 connected to the atmosphere, its output port is connected to the pressure control unit 2, and the gas path output port 29 of the pressure control unit 2 is connected to the pressure detection unit 4 ( figure 2 The middle thick line represents the connection of the gas circuit); the pressure control unit 2 is also connected with the gas pressure generation unit 1 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com